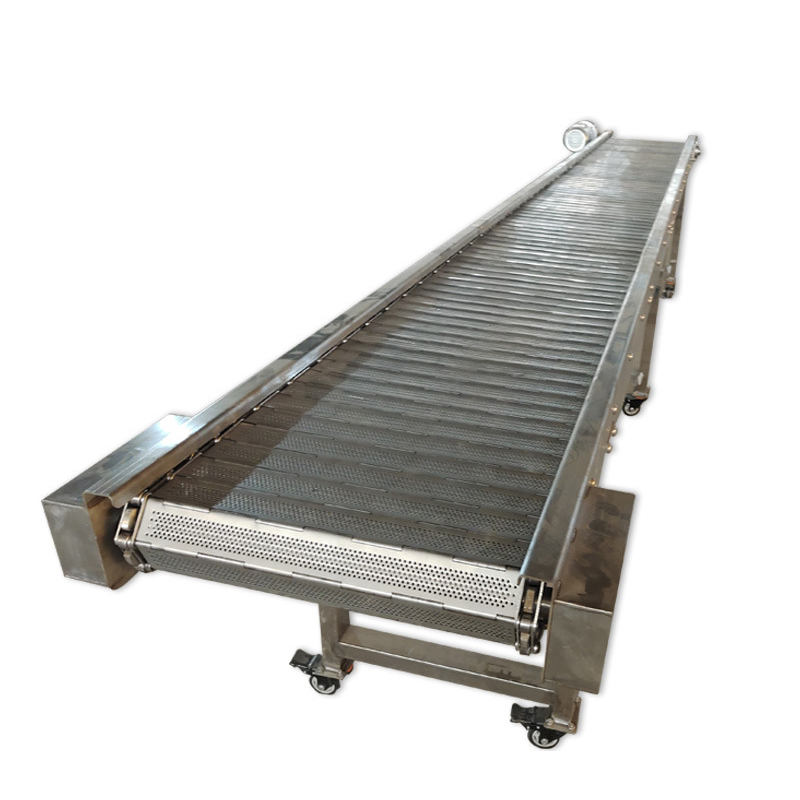

The main structural components of chain conveyor

Chain: As a core component, it is made of high-quality alloy steel or carbon steel, has high tensile strength and wear resistance, and can carry heavy-duty materials. Common chain types include sleeve roller chain, bent plate chain, etc.

Sprocket: It precisely meshes with the chain to transmit power. The surface is specially treated, wear-resistant and runs smoothly, ensuring smooth chain transmission.

Frame: It is welded from steel sections, with a stable structure, supporting the entire conveying system and ensuring stable operation of the equipment.

Drive device: It includes motors and reducers. Different power motors and reduction ratio reducers can be selected according to the conveying requirements to provide stable power output.

Tensioning device: Automatically or manually adjust the chain tension to prevent the chain from being loose or too tight, and ensure the normal operation of the equipment.