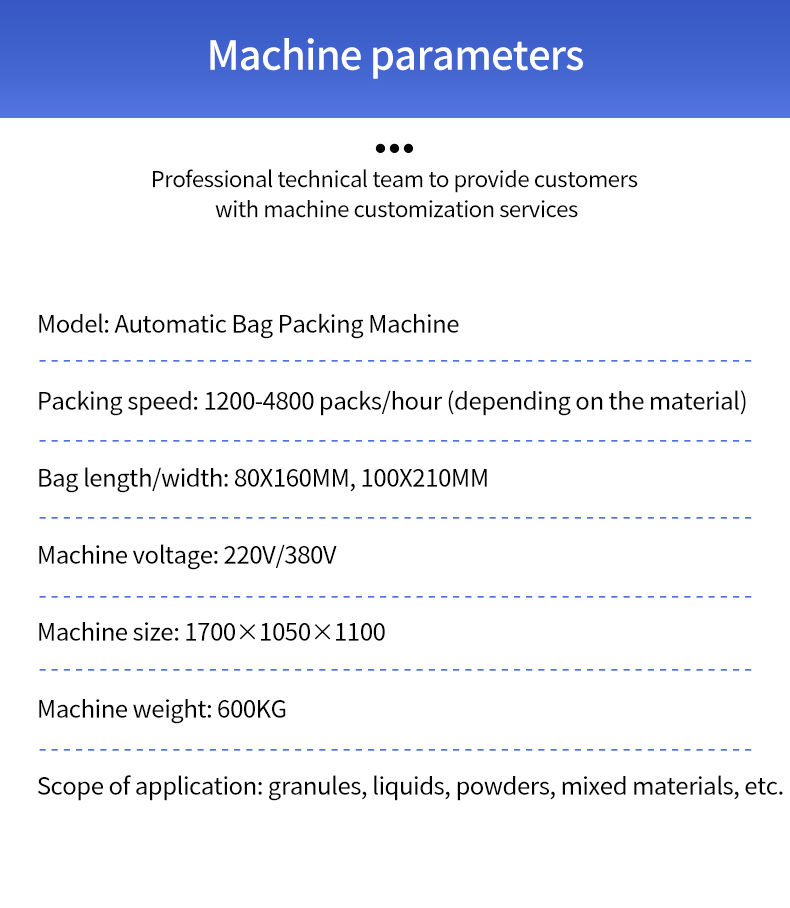

Full automatic bag packing machine

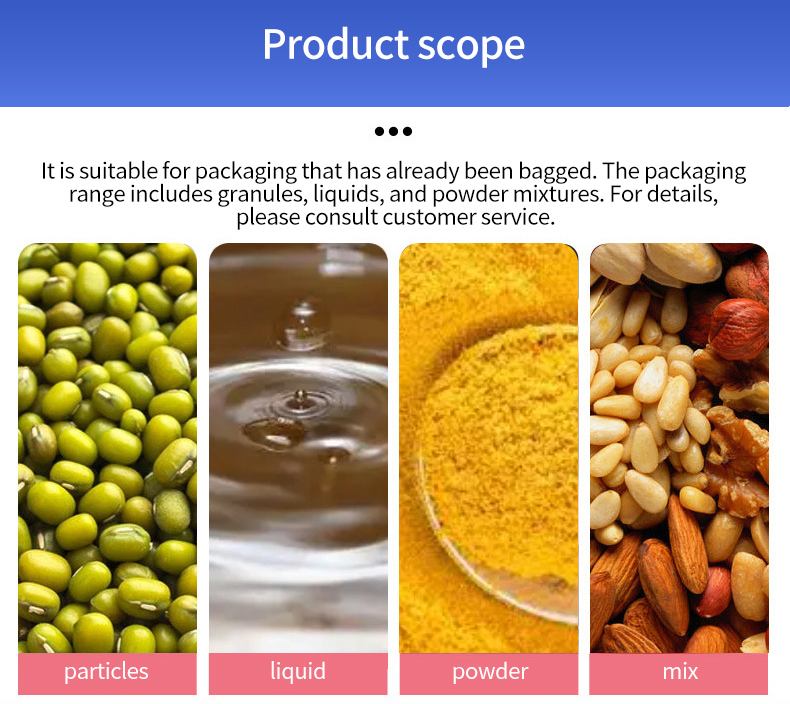

1. Versatility: Food packaging machines are suitable for various food types, such as solid, liquid, powder, etc., and can meet the packaging needs of different foods.

2. Efficient automation: This type of machine is usually highly automated and can quickly complete the packaging process and improve production efficiency.

3. Hygiene and safety: Food packaging machines are usually made of materials that meet food hygiene standards, which can ensure the hygiene and safety of food packaging.

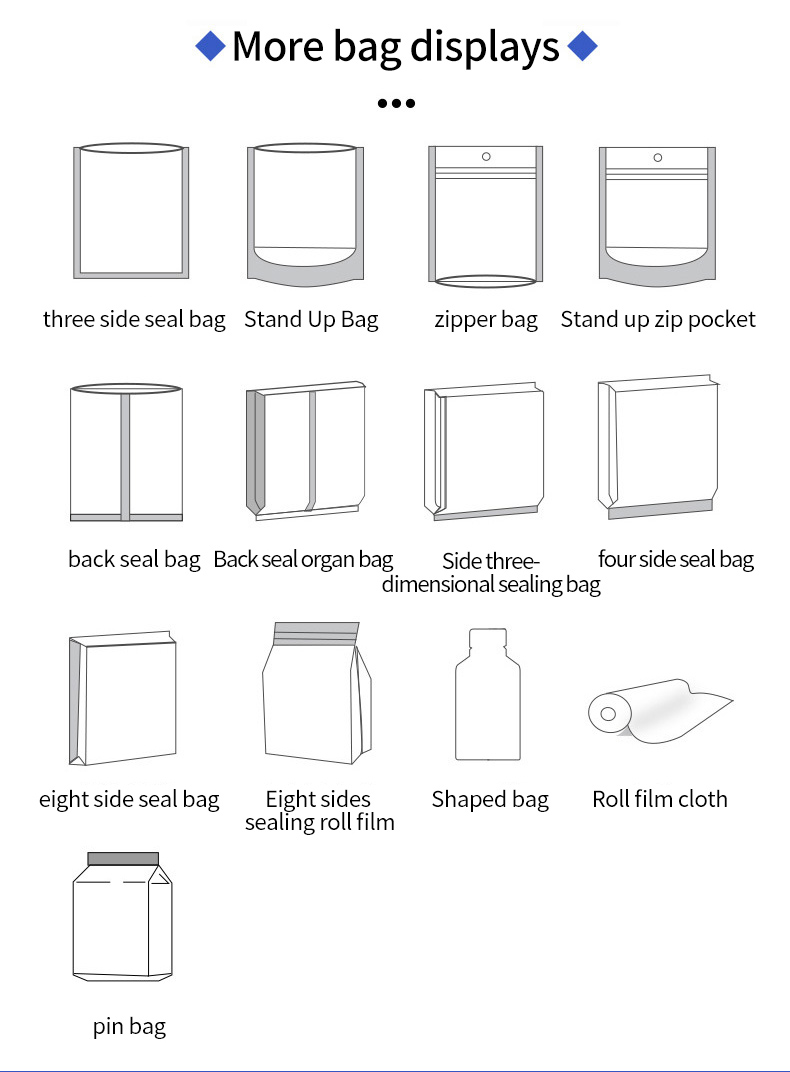

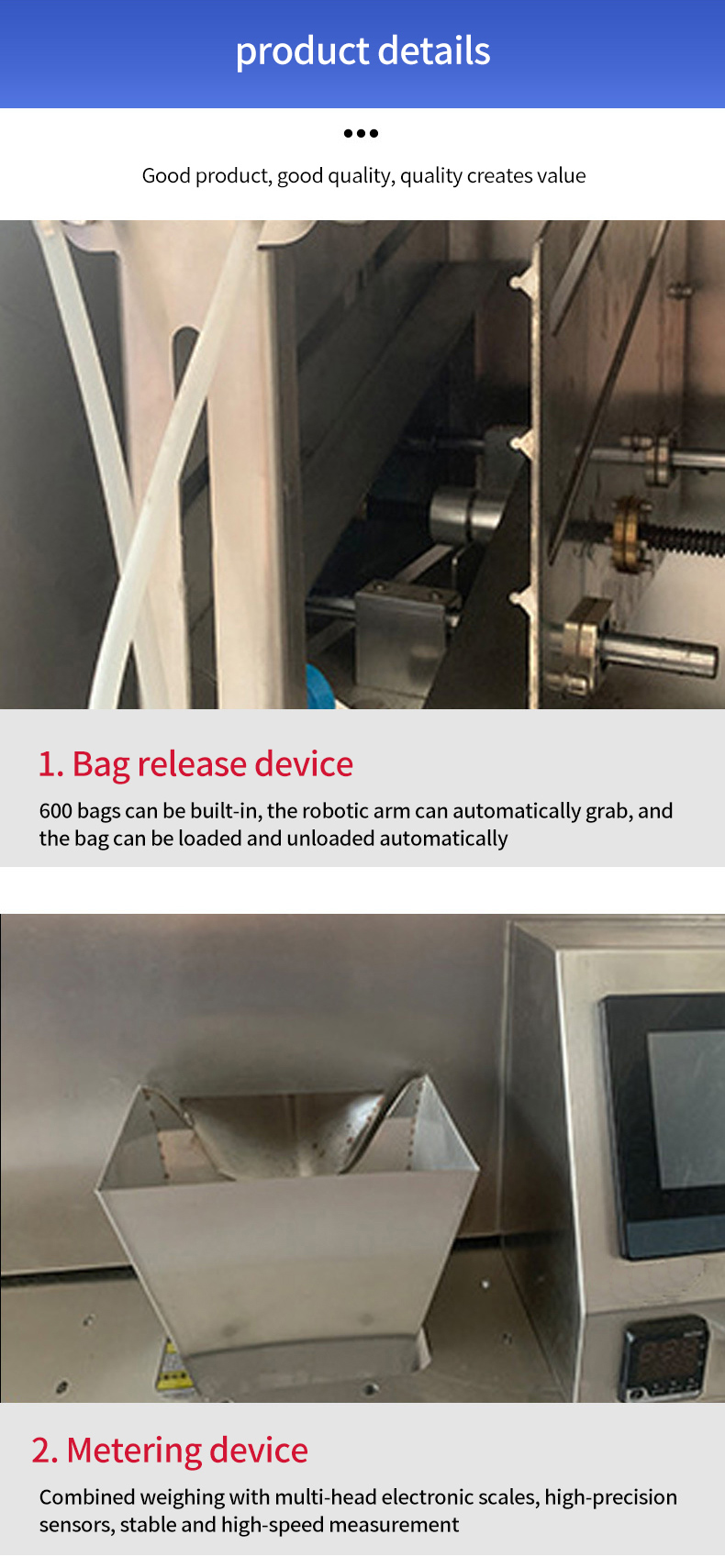

The bag type automatic packaging machine is usually composed of two parts: the bag feeding machine and the weighing machine. The weighing machine can be a weighing type or a screw type, and particles and powder materials can be packed. The working principle of the machine is to use the manipulator to take the user's prefabricated bag, open the bag, bag and seal, and at the same time complete the filling, coding and other functions under the coordinated control of the microcomputer, so as to realize the automatic packaging of the prefabricated bag.

Its characteristic is that the robot replaces the manual bagging, which can effectively reduce the bacterial pollution of the packaging link, and improve the level of automation. It is suitable for the automatic packaging of small quantities of food, condiments and other products. The disadvantage is that the prefabricated bag is required to remove static electricity, otherwise it is easy to take double bags and open bags. It is also inconvenient for the machine to change the packaging specifications.