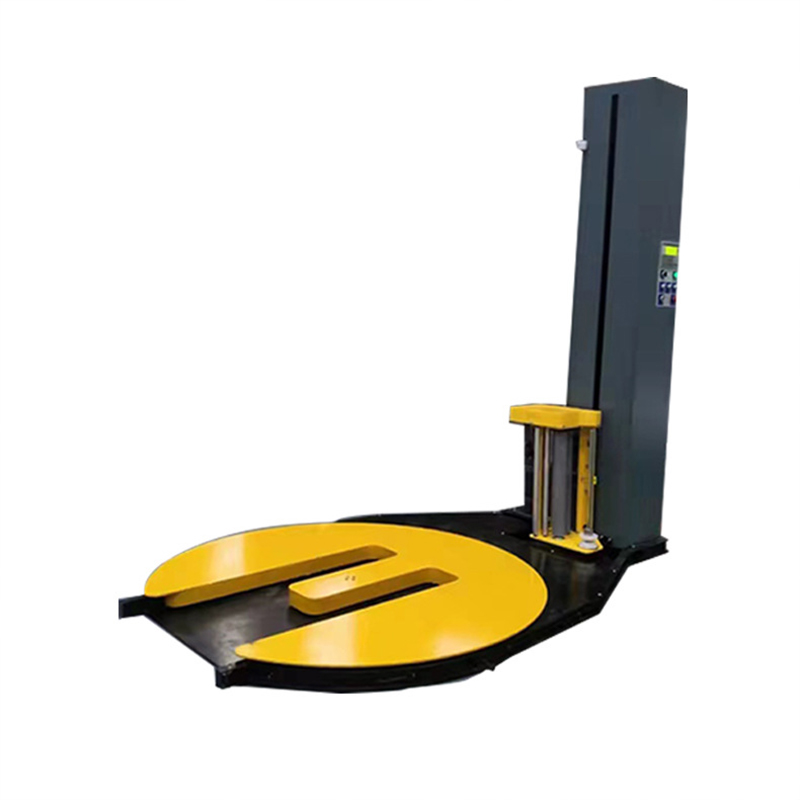

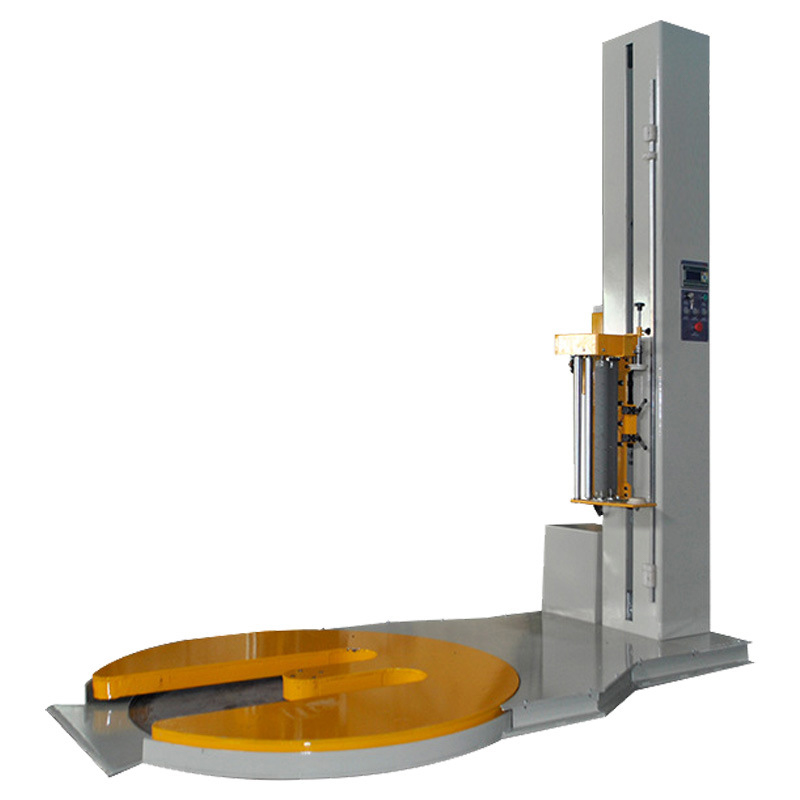

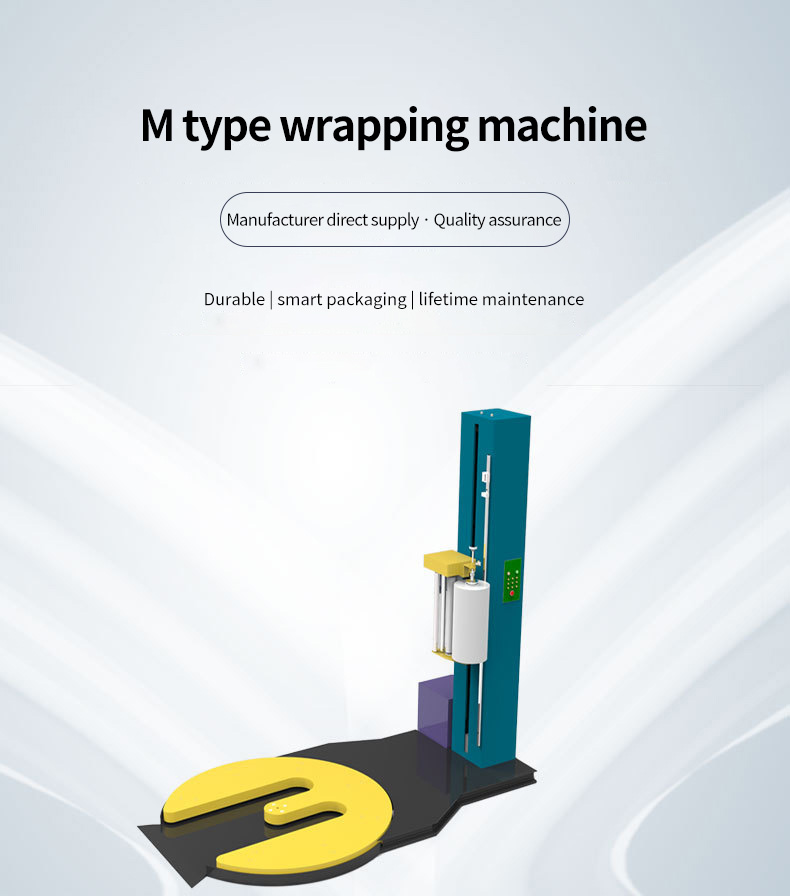

M type automatic wrapping machine

1. The M-type automatic packaging machine adopts advanced packaging technology and design, which can wrap the product tightly, making the packaging appearance neat and beautiful.

2. The appropriate packaging material can be selected according to the characteristics of the product, which can effectively protect the product from the influence of external environmental factors.

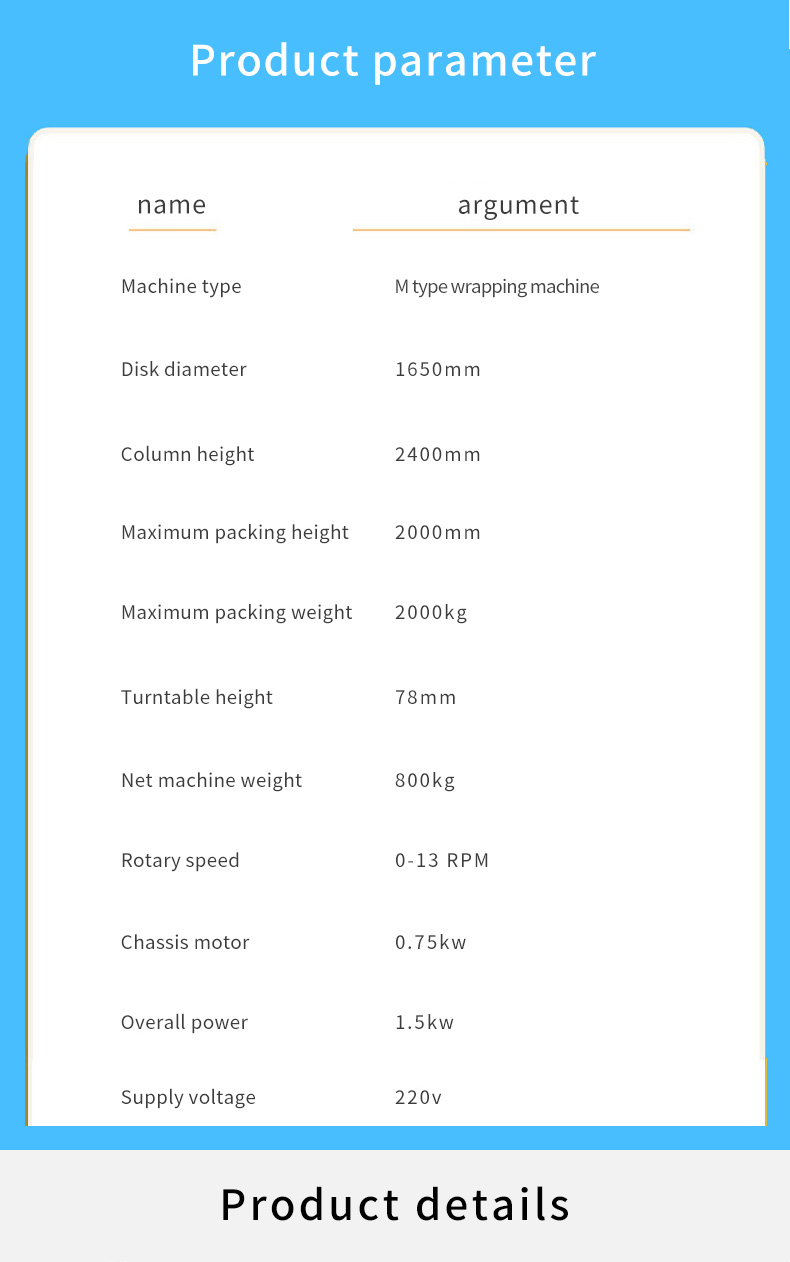

3. Through precise packaging technology and control system, the M-type automatic packaging machine can accurately control the amount of packaging materials.

4. The M-type automatic packaging machine has a high packaging speed, which greatly improves production efficiency. Its degree of automation is high.

5. This type of packaging machine adopts high-quality parts and advanced manufacturing technology, and the equipment has high stability and reliability.

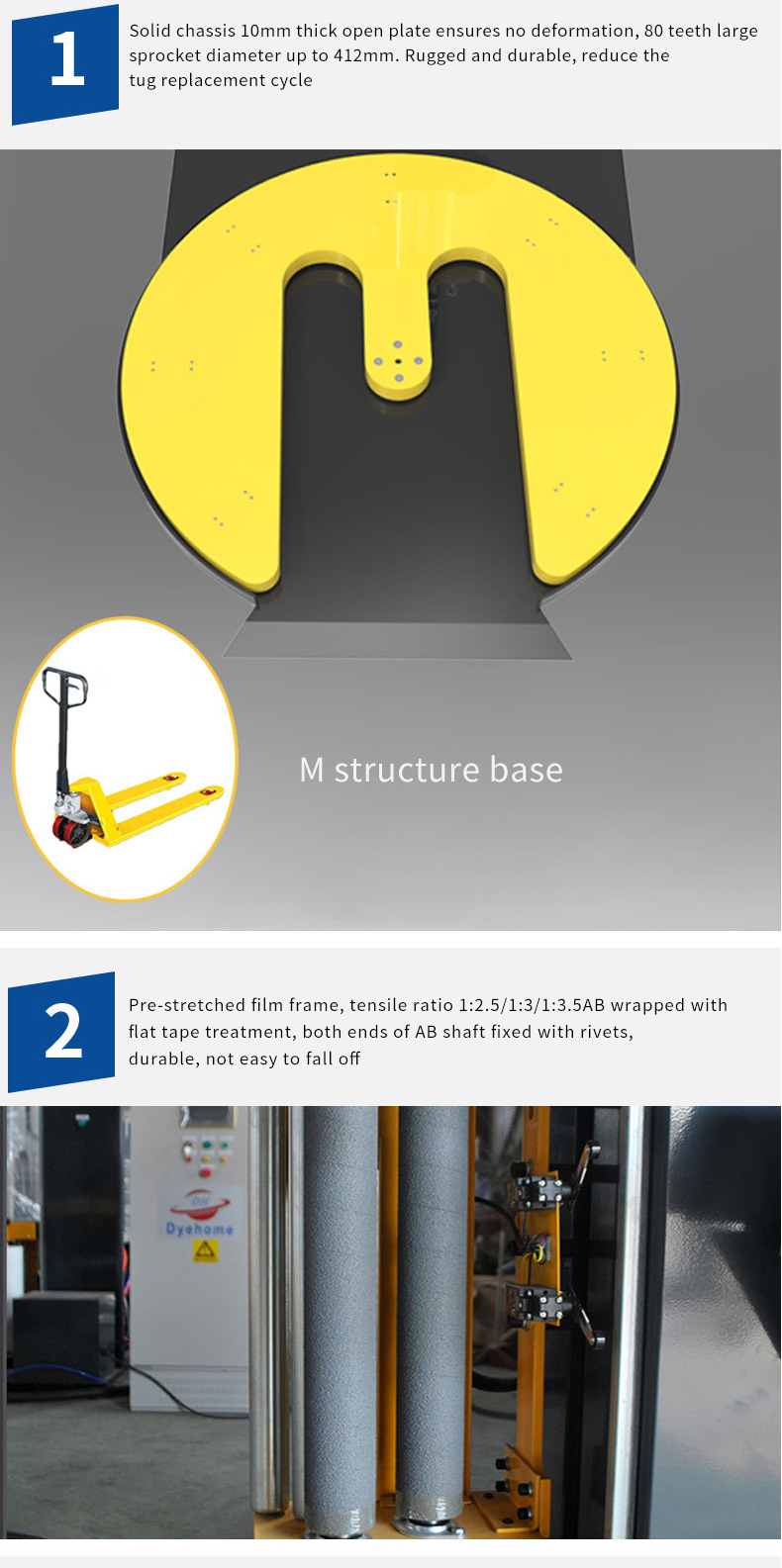

Usually made of solid metal materials such as stainless steel or carbon steel, it has good stability and durability and can withstand long-term operation and heavy workloads.

The power is transmitted to each working part by means of chains, belts or gears to ensure the stable operation and accurate movement of the packaging machine.

Used to install and convey packaging film. The film racks of some packaging machines have a pre-stretching function, which can save packaging materials and improve packaging effects.

It can automatically complete the entire packaging process including feeding, packaging, sealing and discharging, reduce manual operations, improve production efficiency and reduce labor intensity.

Equipped with high-precision sensors and control systems, it can accurately control the amount of packaging materials, sealing position, packaging size, etc. to ensure the consistency and accuracy of packaging.

Packaging parameters such as packaging speed, sealing time, temperature, number of wrapping layers, etc. can be flexibly adjusted according to the packaging requirements of different products.

It is mainly used for wrapping pallet cargo and is suitable for logistics, warehousing, manufacturing and other industries. It can fix cargo on pallets to prevent it from scattering and shifting during transportation and storage, thus protecting the cargo.