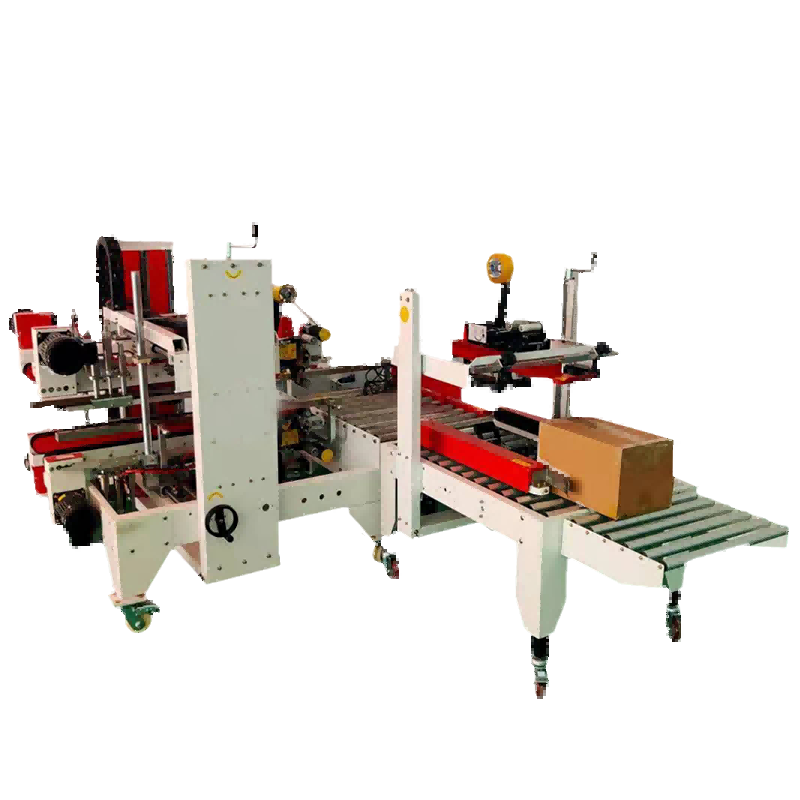

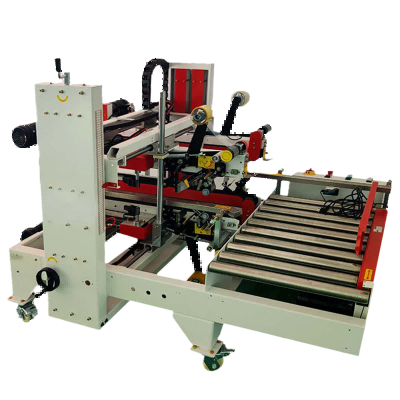

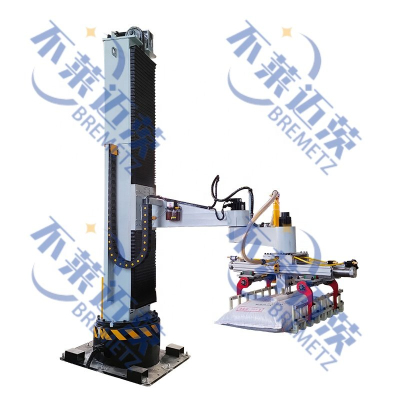

Automatic carton sealing machine

1. Equipped with high-speed motor and precise mechanical transmission system, it can achieve a high number of carton sealing per minute.

2. It can run continuously for a long time without obvious performance degradation. It can adapt to high-intensity packaging operations.

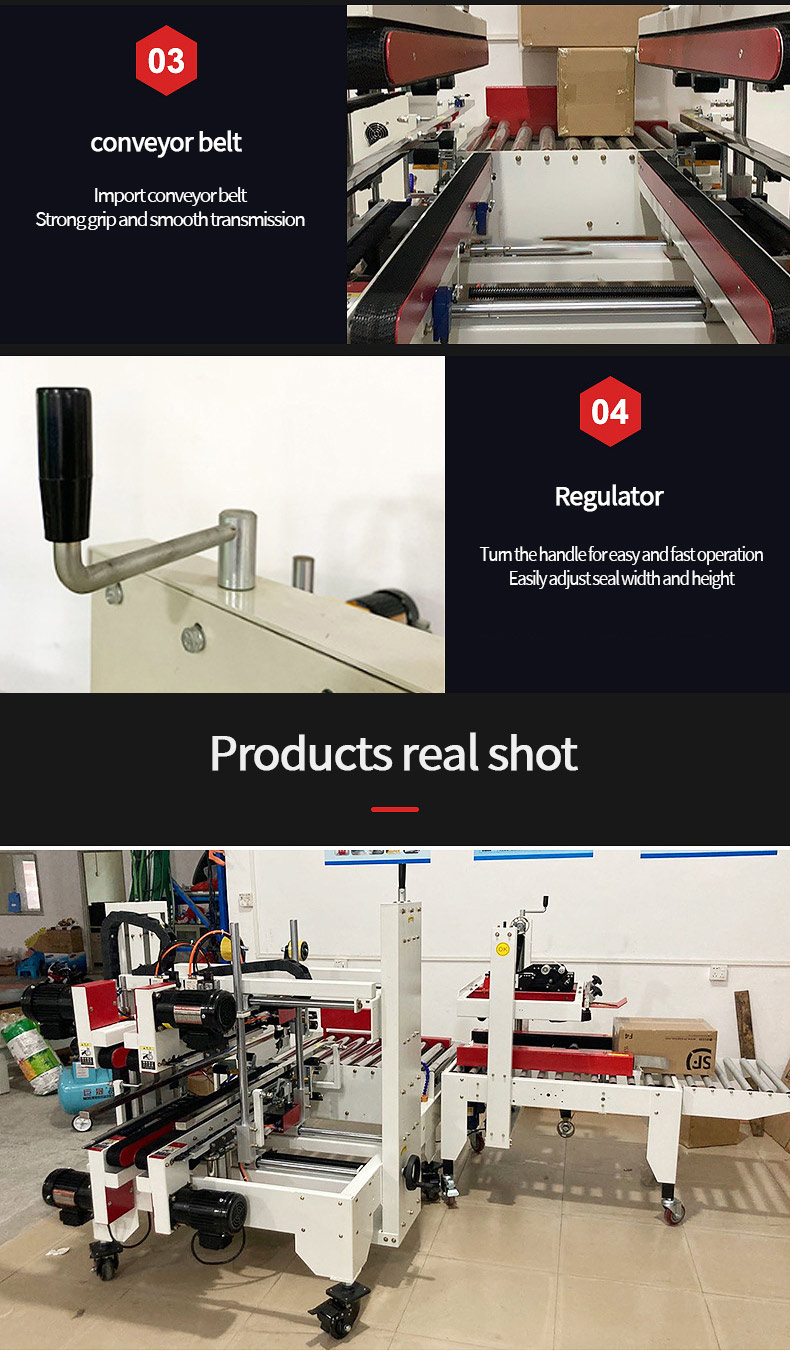

3. Through the precise pressure adjustment device and high-quality tape pasting mechanism, it can ensure that the tape is tightly and firmly pasted on the carton.

4. The machine's tape cutting and pasting actions are precisely coordinated, so that the edges of the tape after sealing are neat and the appearance of the carton is neat.

5. In addition to automatic sealing, it can also integrate functions such as automatic folding and automatic adjustment of carton position.

It can realize continuous carton sealing operation, and the sealing speed is usually fast, which can reach 30 cartons per minute or even higher, greatly improving the packaging efficiency and is suitable for large-scale production and logistics packaging operations.

Through precise mechanical structure and control system, it ensures that the tape or glue is firmly attached to the carton, the seal is tight, neat and beautiful, and the carton seal is effectively prevented from cracking during transportation and storage, ensuring the safety of the product.

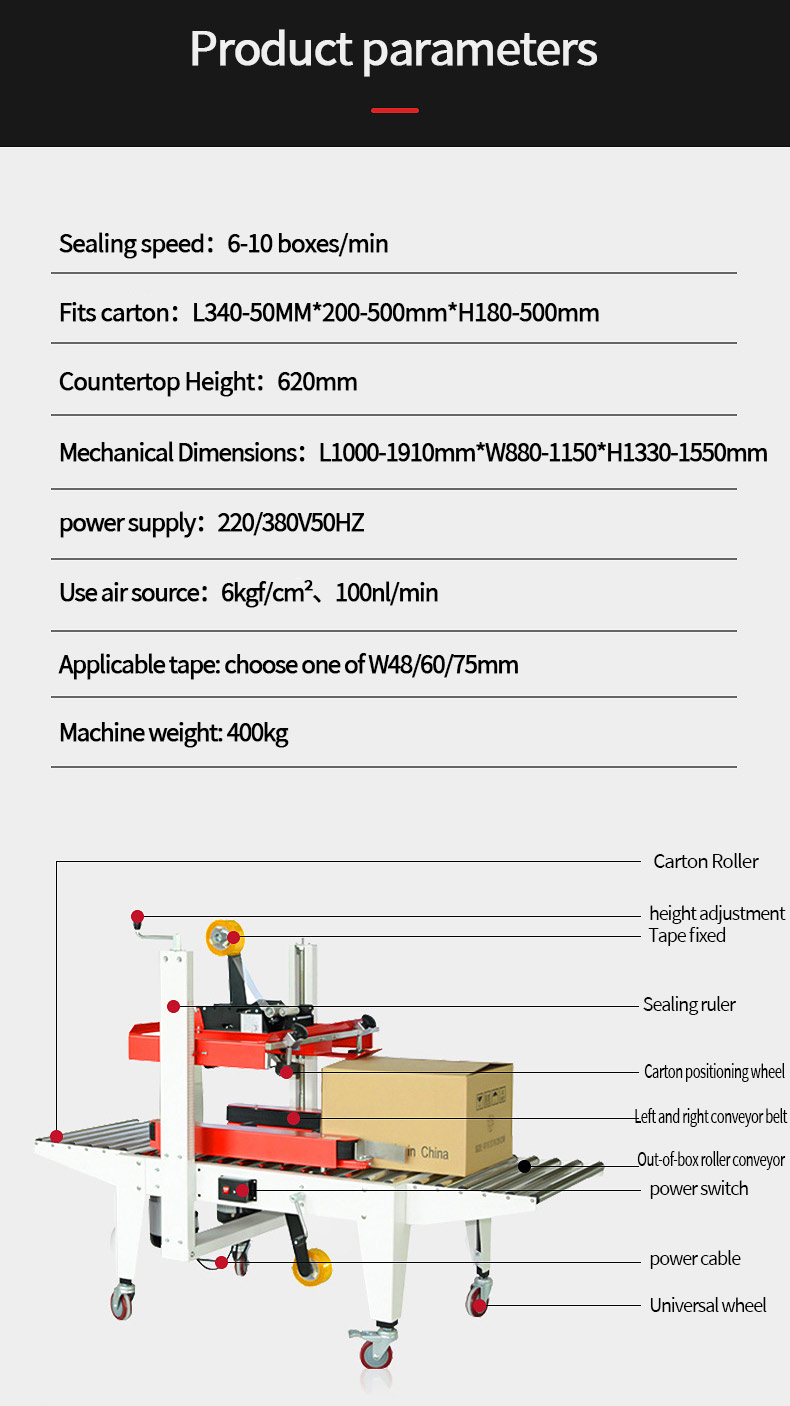

Sealing speed: 6-10 boxes/min

Fits carton: L340-50MM*200-500mm*H180-500mm

Countertop Height: 620mm

Mechanical Dimensions: L1000-1910mm*W880-1150*H1330-1550mm

power supply: 220/380V50HZ

Use air source: 6kgf/cm²、100nl/min

Applicable tape: choose one of W48/60/75mm

Machine weight: 400kg

It has the functions of automatic induction start, automatic folding, automatic adjustment of carton position, etc., which reduces manual intervention, reduces labor intensity, and improves the consistency and stability of packaging. Some advanced models can also form an automated production line with other packaging equipment such as cartoning machines, labeling machines, inkjet printers, etc. to achieve full automation of the packaging process.

It can adapt to cartons of different sizes, shapes and materials, and can meet various packaging needs by simply adjusting or replacing some accessories. At the same time, it is also compatible with a variety of packaging materials, such as ordinary tape, printing tape, hot melt adhesive, etc.

The use of advanced control systems and user-friendly operating interfaces, such as touch screens, PLC programmable control systems, etc., enables operators to easily perform operations such as parameter setting, equipment debugging, and fault diagnosis. It also has automatic fault alarm and prompt functions, which facilitates timely troubleshooting and improves the operating efficiency and reliability of the equipment.