High-efficiency and precise aluminum foil sealing machine

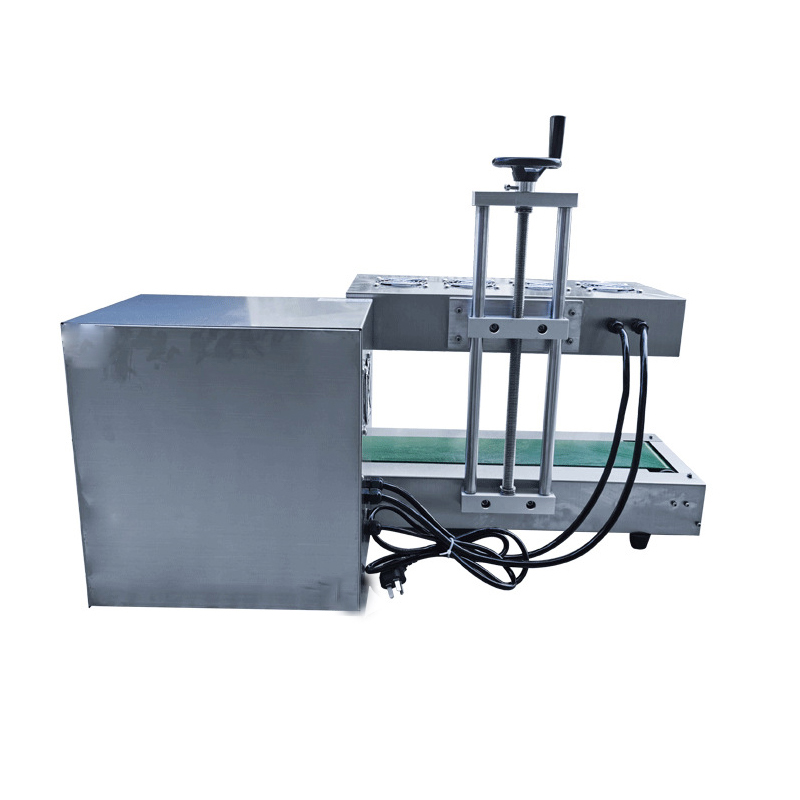

1. The use of advanced power system and optimized mechanical structure makes the sealing action fast and stable. Greatly improves production efficiency.

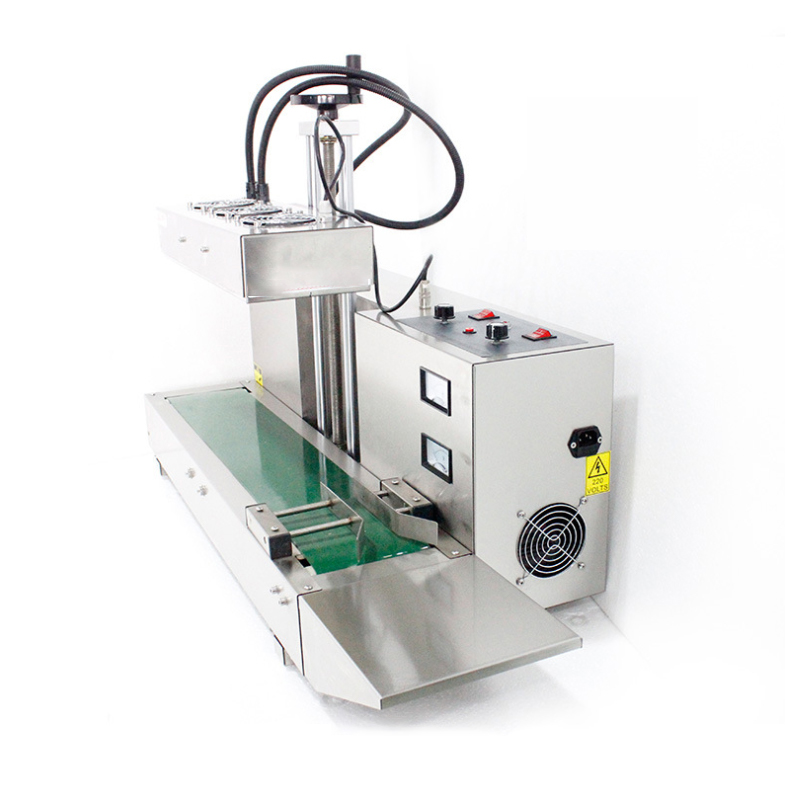

2. The power components such as the motor have good heat dissipation performance, and the mechanical transmission part uses wear-resistant materials to reduce wear and failure caused by long-term operation.

3. Equipped with a high-precision sealing parameter adjustment system, the operator can accurately adjust the parameters according to different product packaging.

4. Through the combination of precise mechanical guide devices and advanced control systems, it is ensured that the aluminum foil can fit the packaging container along a precise trajectory during the sealing process.

5. It can be applied to a variety of packaging containers and aluminum foil materials, including various plastic bottles, glass bottles, cans, and aluminum foils of different thicknesses and materials.

It has the characteristics of high-speed sealing and strong continuous working ability. It can complete the sealing work of a large number of products in a short time and meet the needs of large-scale production.

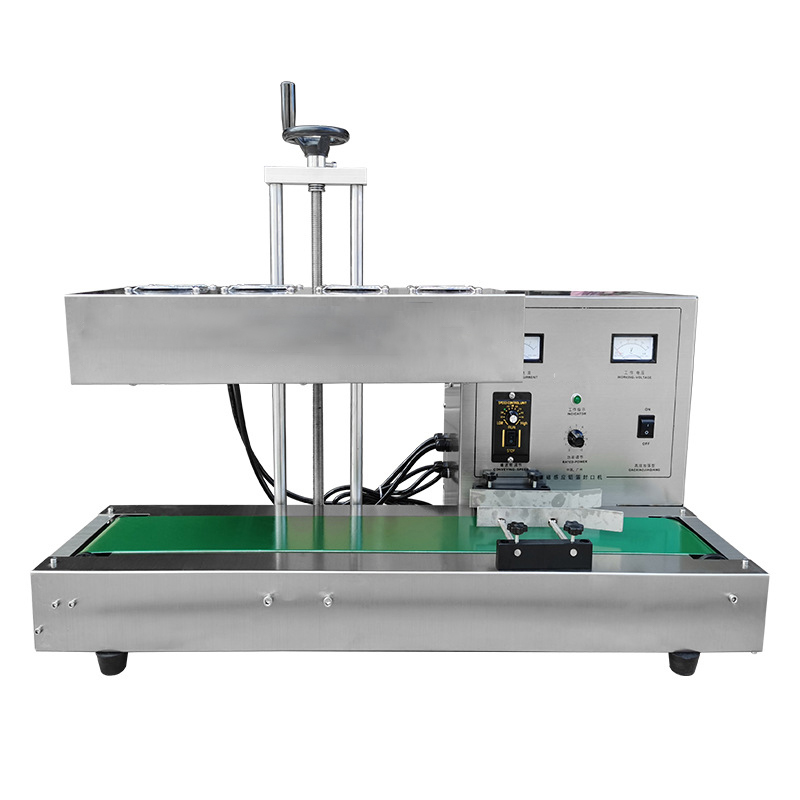

Equipped with a high-precision sealing parameter adjustment system, it can accurately control sealing parameters such as temperature, time, and pressure to ensure the stability and consistency of sealing quality.

It is compatible with a variety of packaging forms and can be used for packaging containers and aluminum foil materials of different materials, shapes and sizes. Some models also have additional functions such as coding and nitrogen filling.

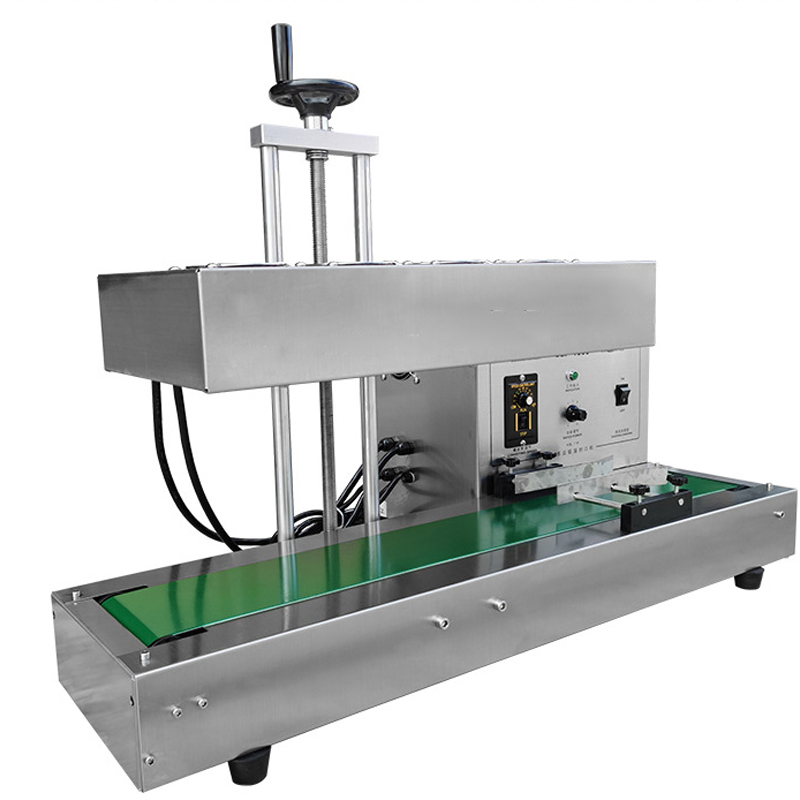

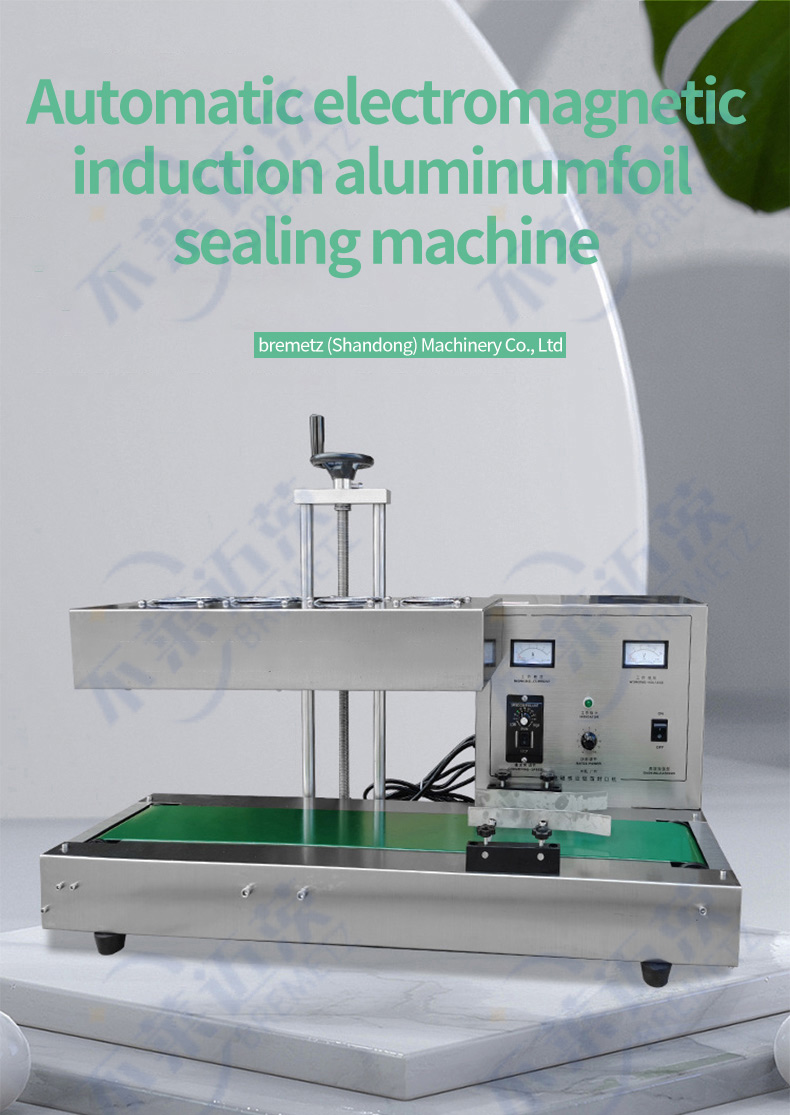

Product name:Electromagnetic induction sealing machine

Sealing diameter:15-60/35-85/50-120(mm)

Sealing speed:20-50 bottles/min

Sealing height:20-280mm

Product material:Stainless steel body

Conveying speed:0–12.5 m/min

Motor power:220V/2200W

Overall dimension:90*45-50cm

The operation interface is intuitive and convenient, and ordinary workers can operate it after simple training; the intelligent control system can automatically monitor and adjust various parameters in the sealing process, and has fault diagnosis and remote monitoring functions.

Multiple safety protection devices are set up, such as protective doors, guardrails, grounding protection, leakage protection, etc., to ensure the safety of operators; using high-quality materials and advanced manufacturing technology, the equipment has reliable quality, long service life, and provides good after-sales service.