Bottle cap sealing machine

1. The machine can work continuously and stably without being affected by factors such as fatigue. It can seal bottles uninterruptedly, reducing the downtime in the production process.

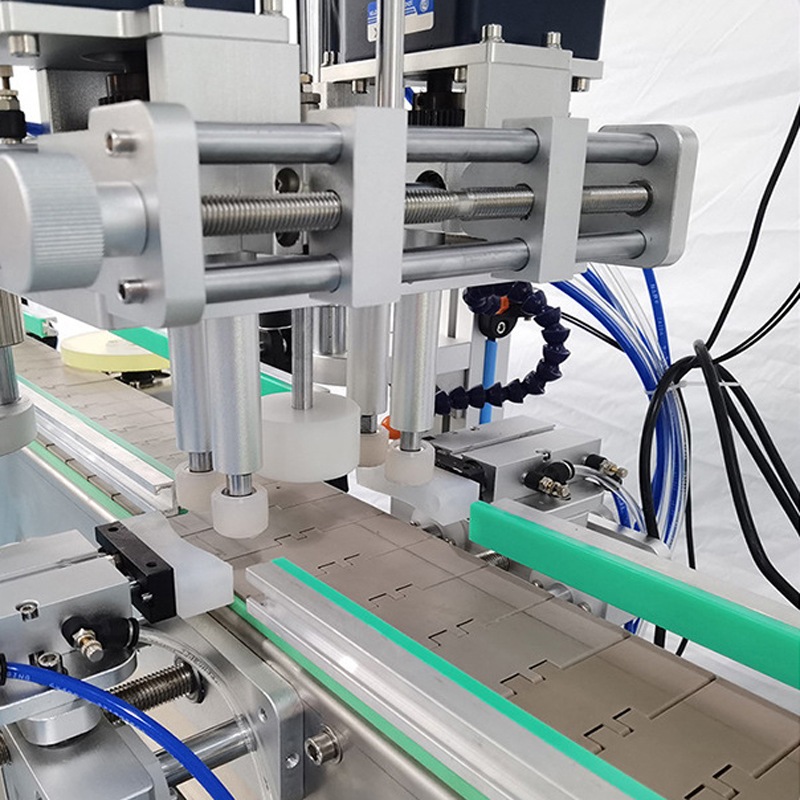

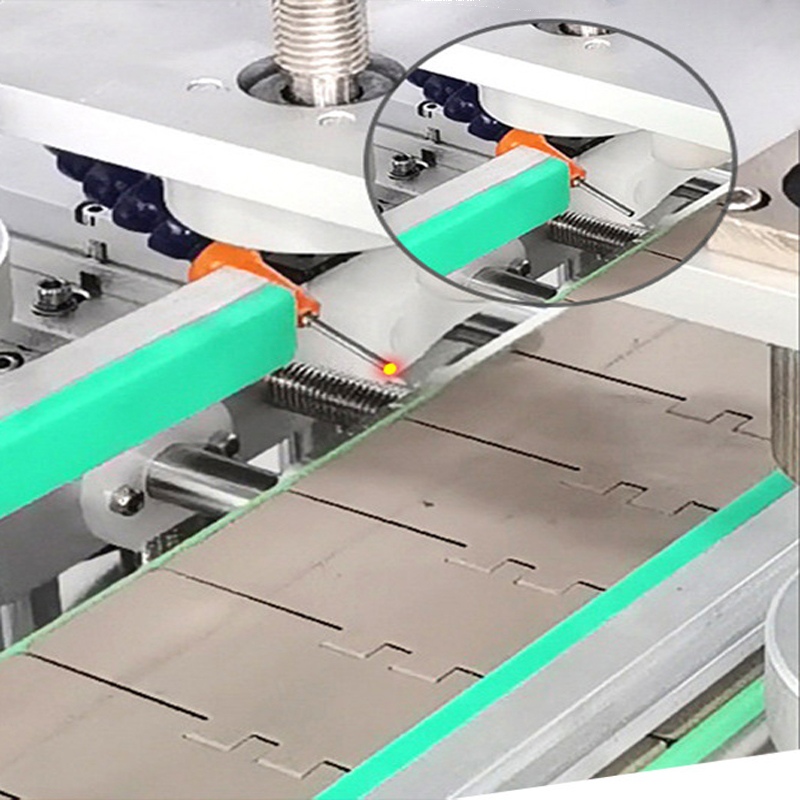

2. Through precise mechanical structure and pressure control system, it can ensure that the bottle cap fits tightly with the bottle mouth to form a good sealing effect.

3. The sealing quality of each bottle can be highly consistent. It makes the appearance of the product more neat and beautiful, and improves the overall quality and brand image of the product.

4. It can handle a variety of bottle shapes and bottle cap types. Whether it is round, square or special-shaped bottles, as well as bottle caps of different materials such as plastic caps, metal caps, aluminum foil caps, etc., you can find a suitable sealing method on the corresponding bottle sealing machine.

5. It can adapt to bottles and caps of different sizes by simply adjusting or replacing some accessories.

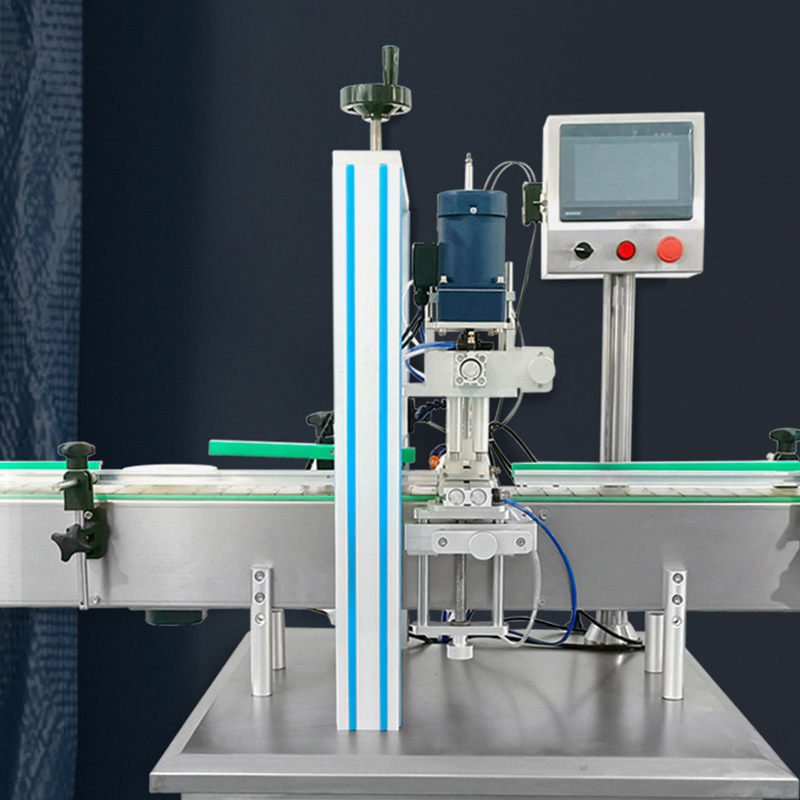

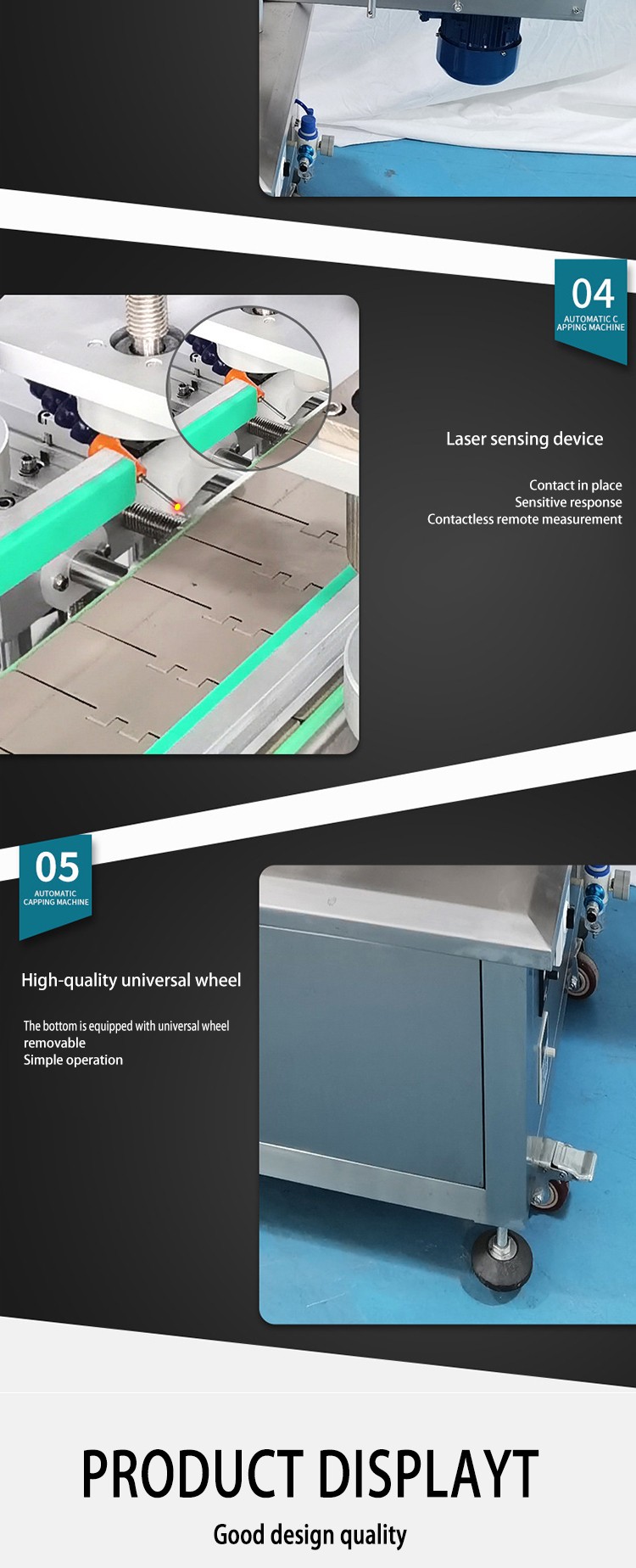

The body is usually made of materials such as stainless steel or aluminum alloy, which is durable, corrosion-resistant, and easy to clean, providing stable support and protection for the entire machine.

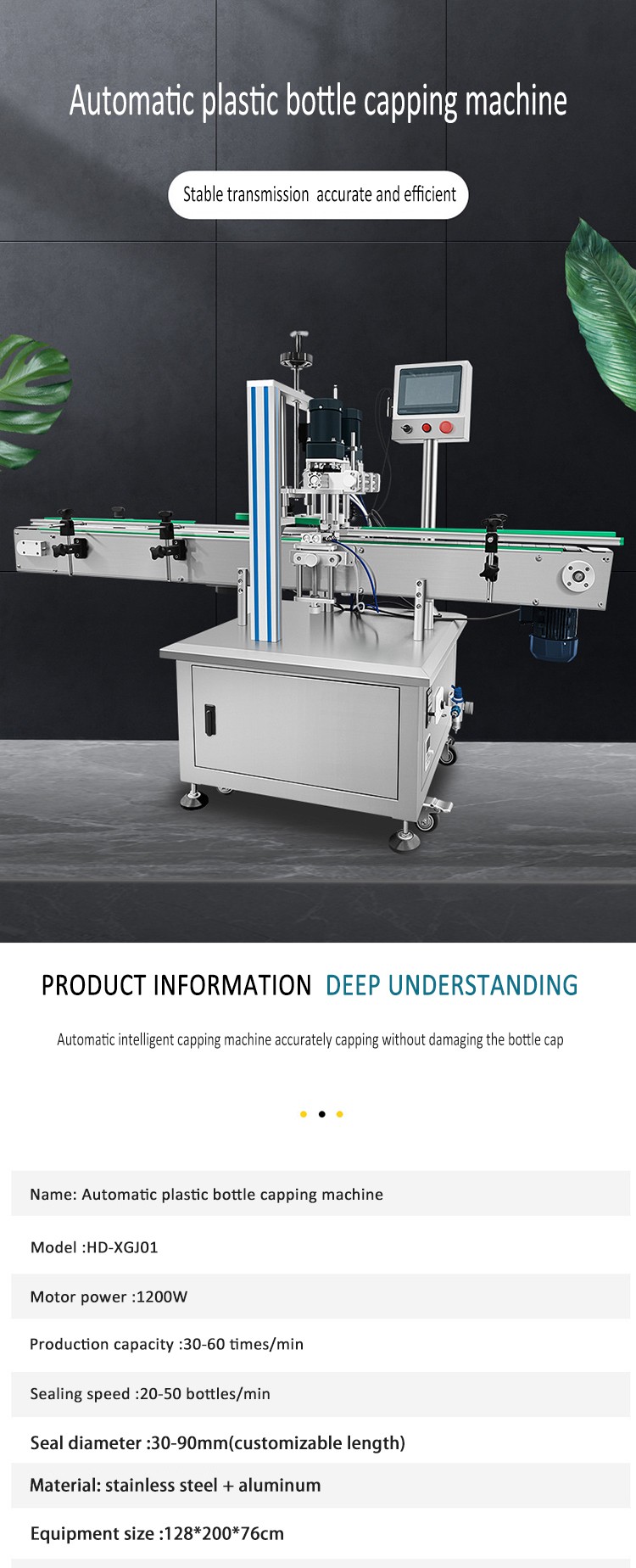

Name: Automatic plastic bottle capping machine

Model: HD-XGJ01

Motor power : 1200W

Production capacity :30-60 times/min

Sealing speed :20-50 bottles/min

Seal diameter : 30-90mm(customizable length)

Material: stainless steel + aluminum

Equipment size:128*200*76cm

With a high sealing speed, it can realize automatic continuous operation, greatly improve production efficiency and reduce labor costs. For example, the fully automatic bottle sealing machine can seal thousands of bottles per hour, which can meet the needs of large-scale production.

It can accurately control parameters such as sealing force, angle and position to ensure a tight fit between the bottle cap and the bottle mouth, consistent sealing quality, and avoid problems such as loose sealing and crooked bottle cap that may be caused by manual operation.

Equipped with multiple safety protection devices, such as emergency stop button, protective door, light curtain sensor, etc., to prevent operators from accidental injuries during machine operation and ensure the safety of the production environment.

The main components are made of high-quality materials and precise manufacturing technology, which ensures the stability and reliability of the equipment during long-term operation and reduces the failure rate and maintenance costs.