Heavy Duty and Durable Collaborative Palletizing Robot

1. Powerful load capacity: With high load characteristics, it can easily handle the stacking task of heavy goods. Its designed load capacity can meet the handling and stacking of heavy objects such as large mechanical parts and building materials.

2. Efficient heavy cargo handling capacity: It shows excellent efficiency when handling large and heavy goods. The movement speed and strength of its robotic arm are optimized, which can quickly and stably grasp and place heavy objects.

3. Use of high-quality materials: High-quality materials such as high-strength alloy steel and wear-resistant alloy are used to manufacture key components. These materials have excellent strength and wear resistance, and can withstand the friction, impact and pressure of heavy objects during long-term use.

4. Strict durability test guarantee: After long-term load testing and fatigue life testing, the durability of the robot in actual use is ensured. These tests simulate various complex and extreme working conditions, and only robots that pass rigorous testing can be put on the market

5. High safety of human-machine collaboration: In the work scenario of handling heavy goods, which has certain dangers, special attention is paid to the safety of human-machine collaboration. Equipped with a complete personnel protection mechanism, it can detect the approach of personnel in real time and automatically stop or adjust the robot's movements when necessary to avoid harm to the operator.

6. Seamless coordination with other equipment: It can achieve seamless docking with peripheral equipment such as conveyor lines and pallet supply systems. The palletizing rhythm can be automatically adjusted according to the flow and type of goods on the conveyor line to ensure the continuous supply and accurate stacking of goods.

7. Efficient palletizing speed and multiple modes: Maintaining a high palletizing speed under heavy load conditions, its optimized robot arm motion path and efficient grabbing/placing actions enable more heavy cargo palletizing tasks to be completed per unit time. This helps to improve production efficiency and meet the palletizing needs of large-scale heavy product production.

In the field of modern industrial production and logistics, the heavy-duty and durable collaborative palletizing robot is a high-performance equipment carefully designed to meet the challenges of heavy-duty cargo palletizing. It combines advanced technology with excellent engineering design to bring reliable and efficient palletizing solutions to enterprises.

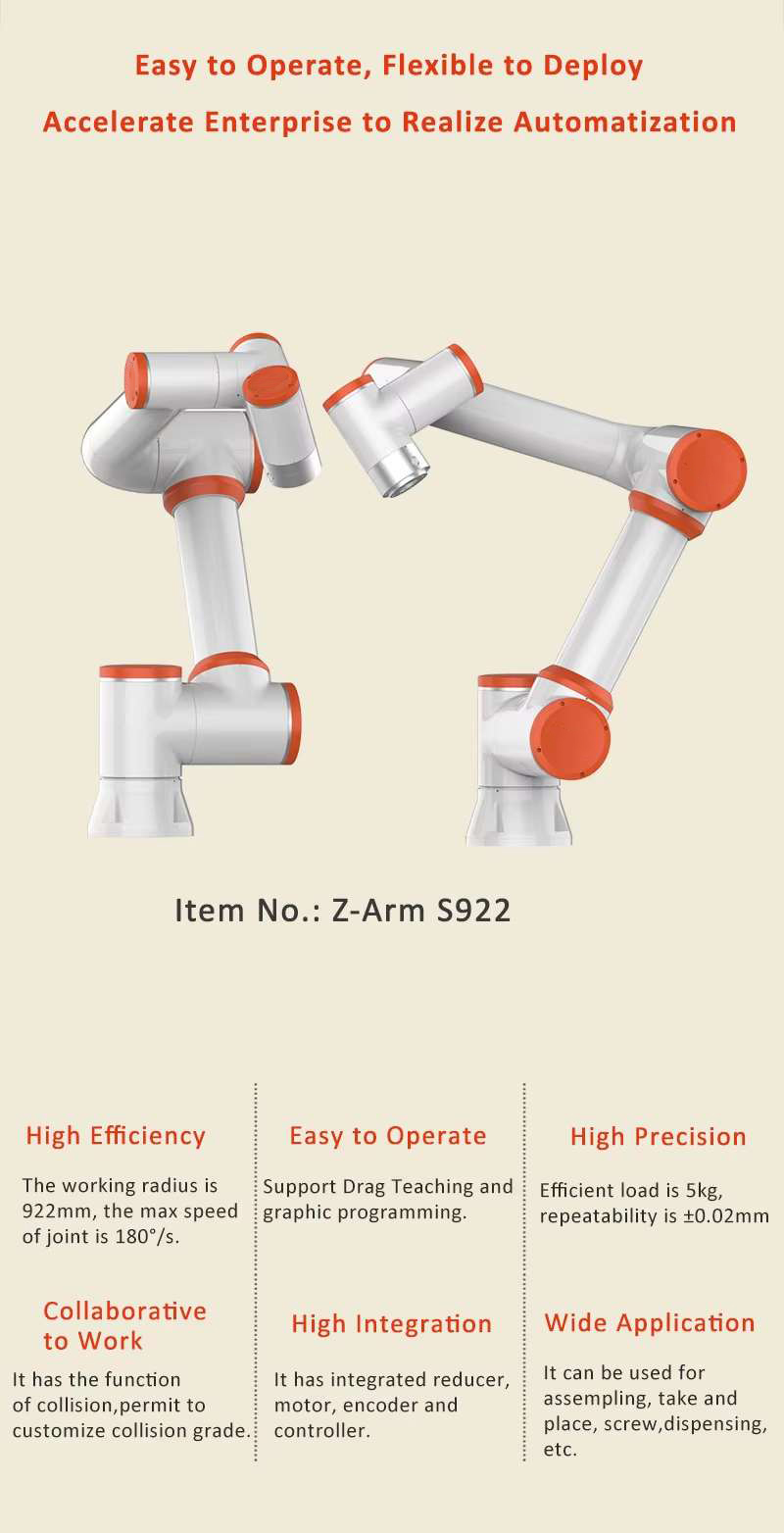

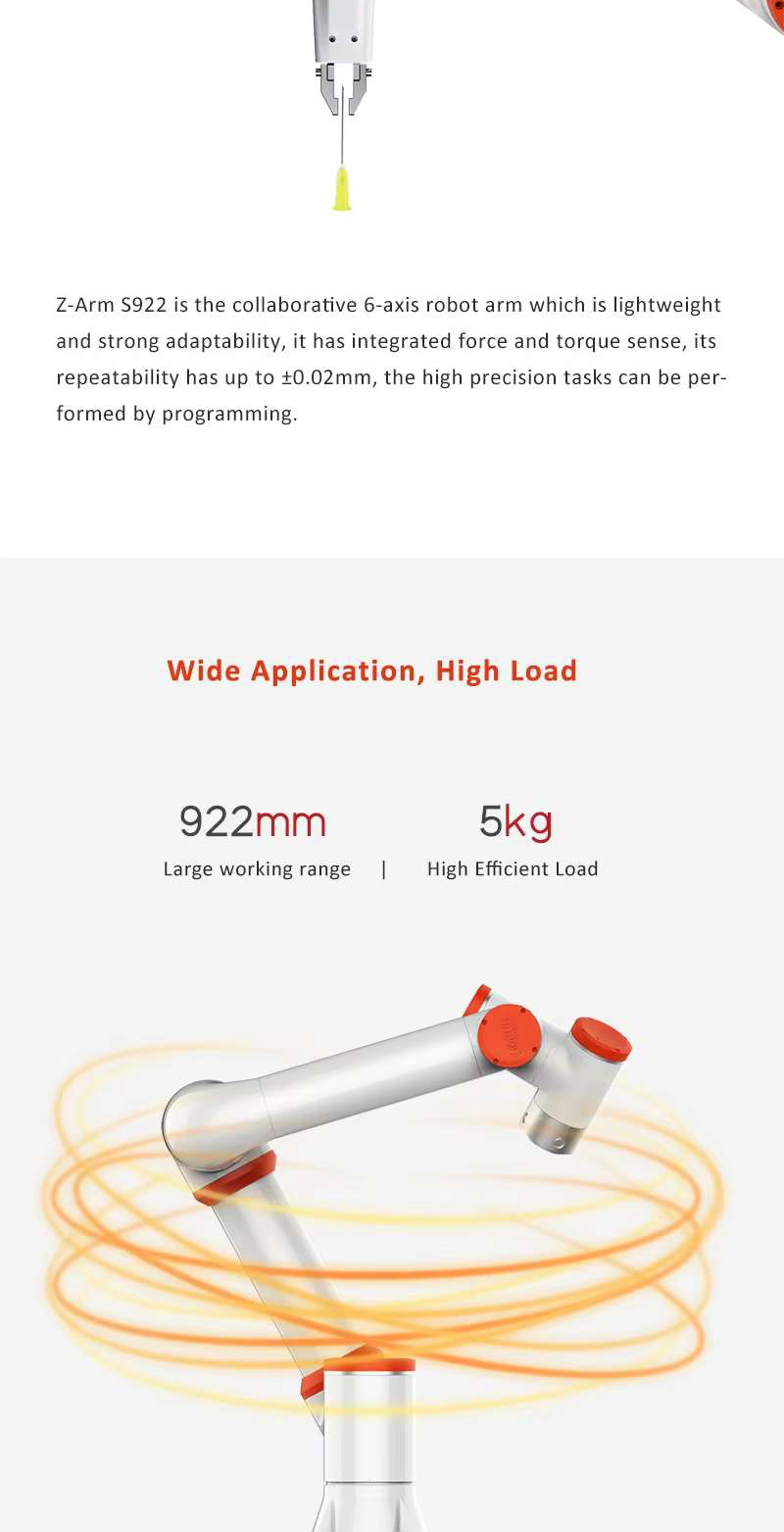

High efficiency: working radius is 922mm, maximum joint speed is 180°/s.

Collaborative work: with collision function, allowing customized collision level.

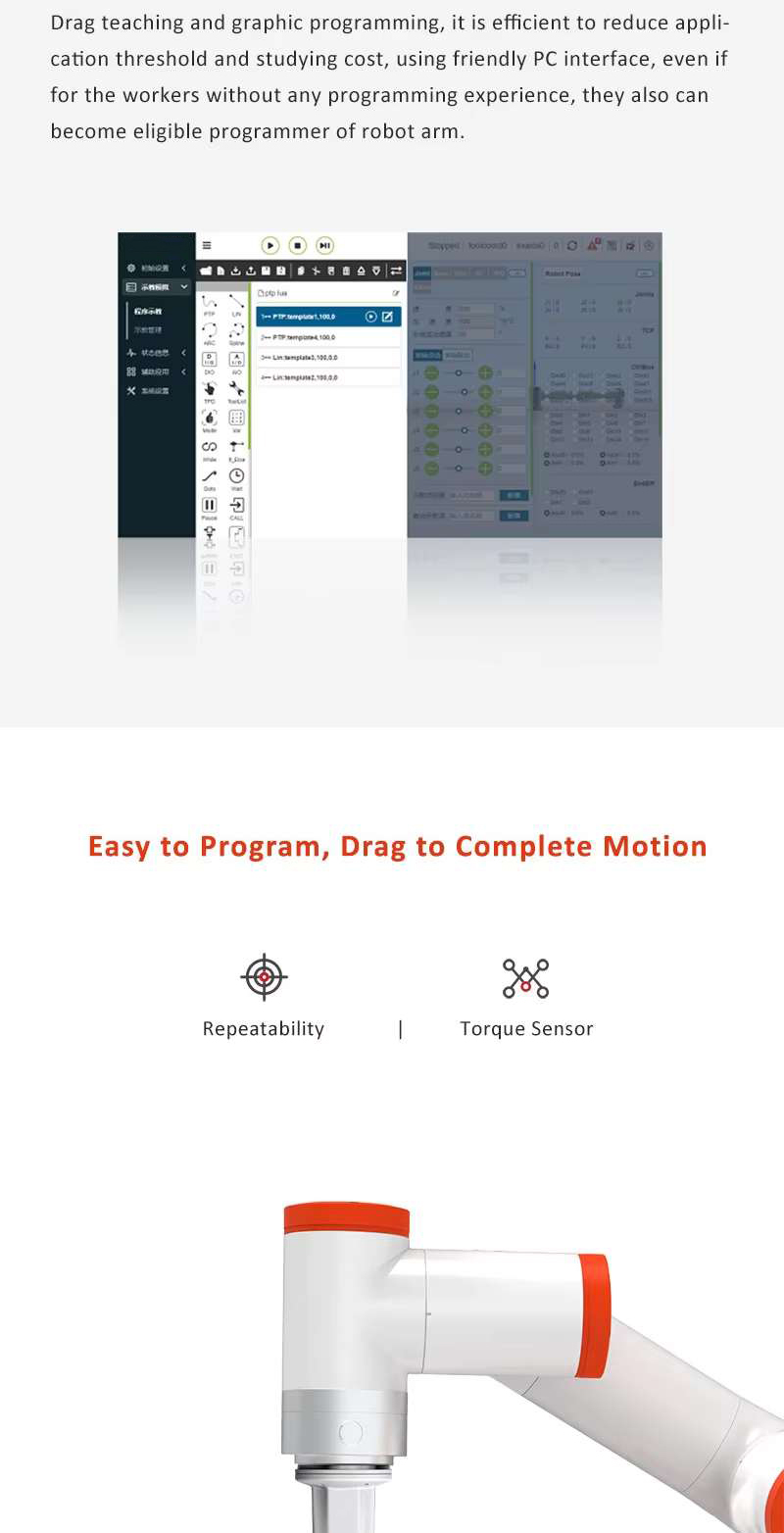

Easy to operate: support drag teaching, graphical programming.

High precision: payload 5kg, repeatability ±0.02mm

High integration; it integrates reducer, motor, encoder and controller.

Wide application: can be used for assembly, pick and place, screwing, dispensing, etc.

The heavy-duty and durable collaborative palletizing robot is extremely sophisticated in material selection. Key components are made of high-quality materials such as high-strength alloy steel and wear-resistant alloy. The joints and transmission parts of the robot arm, which are often subjected to high pressure and friction, use alloy materials with excellent wear resistance and high strength, which can effectively resist wear and fatigue during long-term and frequent heavy cargo handling.

During the research and development process, this robot has undergone long-term rigorous testing. These include long-term load tests and fatigue life tests that simulate actual working scenarios. The test conditions cover various extreme situations, such as overweight loads, frequent starts and stops, and long-term continuous operation.

Whether it is large industrial machinery parts, building materials weighing thousands of pounds, or other heavy goods, it can stably carry and stack them. This powerful load capacity greatly expands the range of goods that can be handled and meets the needs of heavy industry, construction, energy and other industries for heavy goods stacking.

The robot demonstrates high efficiency when handling heavy goods. The movement speed and strength of the robot arm have been carefully optimized to quickly and stably grasp heavy objects. Its unique power system provides a strong driving force for the robot arm, ensuring smooth and seamless movements when grasping heavy goods. In addition, in view of the irregular shapes of heavy industrial products, the robot is equipped with special grasping devices, such as adaptively adjustable grippers and suction cups, combined with advanced intelligent algorithms. No matter how complex the shape of the goods is, it can accurately grasp them and place them firmly on the pallet, greatly shortening the stacking time of heavy goods and improving the efficiency of the entire production process.