Safe and stable collaborative palletizing robot

1. Strong structural stability: The robot's frame and mechanical arm are constructed with high-strength metal materials. After precise processing and welding processes, it is ensured that it will not deform or break under long-term heavy loads and frequent movements. High-quality bolts, nuts and joint components are used in key connection parts, which have good wear resistance and anti-loosening ability.

2. Collaboration with other equipment: It can achieve seamless docking with peripheral equipment such as conveyor lines and pallet supply systems. Through data interaction and precise time control, the robot can accurately grab goods from the conveyor line and transport the pallets to the designated location to ensure the smooth connection of the entire logistics palletizing process.

3. High-speed palletizing: With efficient motion algorithms and powerful power systems, the robot arm moves quickly and smoothly, and can complete the palletizing task of a large number of goods in a short time.

4. Flexible switching of multiple palletizing modes: It supports multiple common palletizing modes, and can automatically or manually switch between different modes according to the characteristics of the goods, maximize the use of pallet space, and improve storage and transportation efficiency.

5. Safety measures for adaptability to the working environment: For complex industrial environments, the robot's shell has good protective performance, which can prevent foreign matter such as dust and liquid from entering the internal circuit and mechanical structure, and avoid safety hazards caused by short circuits, corrosion and other problems caused by foreign matter.

In the field of modern industrial production and logistics warehousing, safe and stable collaborative palletizing robots have become key equipment for improving efficiency and ensuring safety.

The safe and stable collaborative palletizing robot is light, compact, highly flexible and easy to install. The integrated intelligent drive module achieves lightweight design while having superior performance. In addition, the rich secondary development interface provides customers with more choices for different scenarios. The safe and stable collaborative palletizing robot has a small appearance, simple and intuitive operation, low noise, and high cost performance, which is particularly suitable for consumption, service, education and other fields.

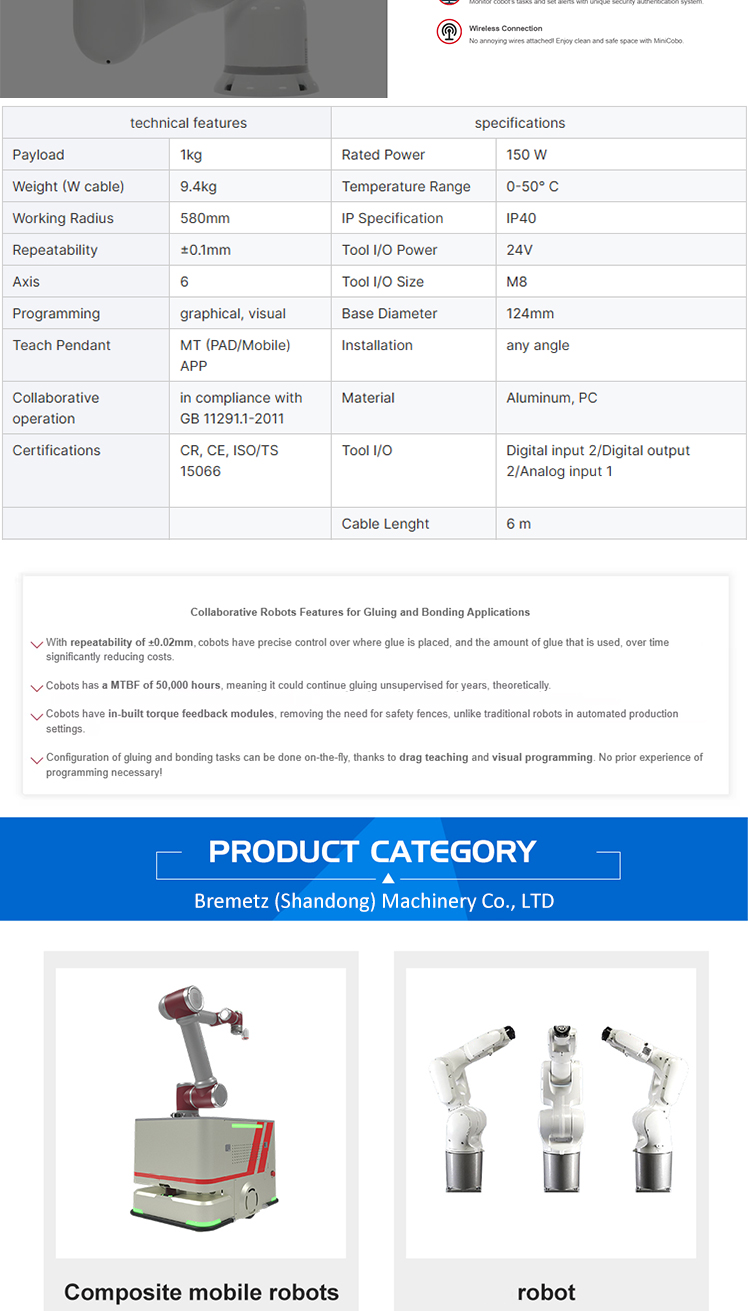

Payload: 1 kg

Rated power: 150 watts

Weight (W cable): 9.4 kg

Temperature range: 0-50°C

Working radius: 580 mm

IP specification: IP40

Repeatability: ±0.1 mm

Tool I/O power supply: 24V

Axis: 6

Programming: M8

Teach pendant: MT (PAD/mobile) APP

Mounting: Any angle

Cooperative operation: Comply with GB 11291.1-2011

Material: Aluminum, polycarbonate

Certification: CR, CE, ISO/TS 15066

Tool input/output: Digital input 2/Digital output 2/Analog input 1

Cable length; 6 meters

Features of safe and reliable collaborative palletizing robots for gluing and bonding applications:With repeatability of ±0.02mm, cobots can precisely control where glue is applied and how much glue is used, significantly reducing costs over time. The MTBF is 50,000 hours, which means it can theoretically continue bonding unattended for several years. Unlike traditional robots in automated production environments, collaborative robots have built-in torque feedback modules so no safety fences are required. Thanks to drag-and-drop teaching and visual programming, gluing and gluing tasks can be configured on the fly. No programming experience required!