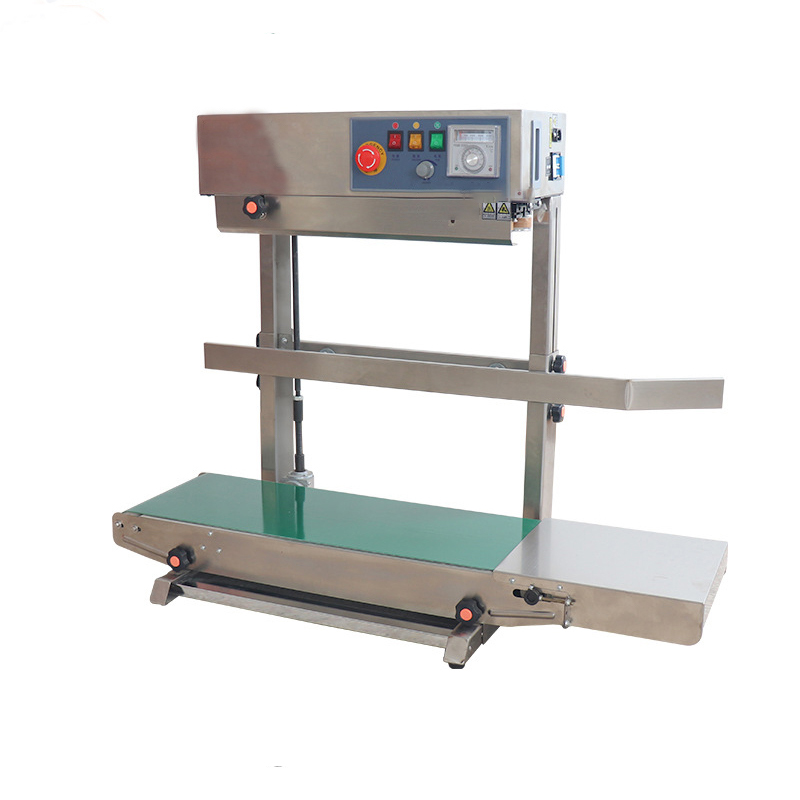

Vertical and horizontal dual-purpose fully automatic film sealing machine

1. It can meet the sealing requirements in both vertical and horizontal directions, and can adapt to products of various shapes, sizes and packaging forms.

2. It is equipped with an advanced automatic control system, which can realize a series of operations such as automatic feeding, automatic sealing, and automatic detection, greatly reducing manual intervention.

3. It adopts precise temperature control and pressure regulation system to ensure the firmness and flatness of film sealing, and effectively prevents leakage, rupture and other quality problems at the sealing point.

4. It has a humanized operation interface, which is easy to operate and master. Operators only need simple training to operate the machine proficiently, set various parameters and perform daily maintenance.

5. The versatility and efficiency of the equipment can reduce energy consumption and waste of raw materials in the production process to a certain extent, and further reduce production costs.

The vertical and horizontal dual-purpose fully automatic film sealing machine adopts an integrated and modular design structure, with a compact and reasonable overall layout and efficient and smooth coordination between various components. The main frame of the machine body is made of sturdy and durable metal material, with excellent stability and vibration resistance.

Equipped with unique vertical and horizontal sealing units, each unit is equipped with high-performance heating elements and precise temperature control systems. The heating elements are made of high-quality heating materials, which can heat up quickly and maintain a stable working temperature.

It has a precise conveyor belt and automatic positioning device. The conveyor belt is made of high-strength, low-friction material and can smoothly convey products of various shapes and weights.

With the advanced programmable logic controller (PLC) as the core, combined with the intuitive touch screen human-machine interface, it realizes the intelligent control and management of the entire sealing machine.

The control system has complete fault diagnosis and alarm functions and can monitor the operating status of the equipment in real time.

Product type:900 vertical

Temperature control range:0~300°C

Machine power supply:0~300°C

Film thickness:2-100 threads

Overall power:750W

Maximum bearing capacity:5KG

Sealing speed:0~12m/min

Sealing width:6-10 min

Sealable height:100-300mm

Machine weight:About 23KG

Machine size:1240×580×1230mm

The unique vertical and horizontal dual-purpose sealing design enables flexible switching of multiple sealing directions and packaging forms on one device, greatly improving the versatility and adaptability of the equipment.Whether it is a simple flat sealing or a complex three-dimensional packaging sealing requirement, it can be completed efficiently, significantly improving production efficiency.

The safety of the equipment during operation is taken into consideration, and it is equipped with complete safety protection devices, such as light curtain sensors, emergency stop buttons, leakage protection, etc. The light curtain sensor can monitor in real time whether there are people or foreign objects entering the working area of the equipment. Once an abnormal situation is detected, the equipment operation will be stopped immediately.

Advanced temperature control, pressure regulation and film tension control systems ensure high precision and stability of the sealing process. It can accurately seal films of different materials and thicknesses, making the sealing area strong, airtight and smooth in appearance.