Fully automatic wet wipes packaging machine

1. Fast production speed, depending on the number of packages, can reach 20-900 pieces per minute, which can greatly improve production efficiency.

2. A series of packaging processes from wet wipes conveying, folding, bag making, filling, sealing to labeling can be completed automatically without excessive human intervention.

3. With excellent sealing technology, it can effectively prevent wet wipes from being contaminated by the outside world during storage and transportation.

4. Not only suitable for the packaging of ordinary wet wipes, but also for the packaging of baby wet wipes, disinfectant wet wipes, wet toilet paper and other special-purpose wet wipes.

5. The design and manufacture of the equipment meet the relevant hygiene standards, using food-grade or medical-grade materials, easy to clean and disinfect.

The overall structure of the fully automatic wet wipes packaging machine is compact and the layout is reasonable. It is mainly composed of a frame, a transmission system, a bag making system, a filling system, a sealing system, a control system and a material conveying system.

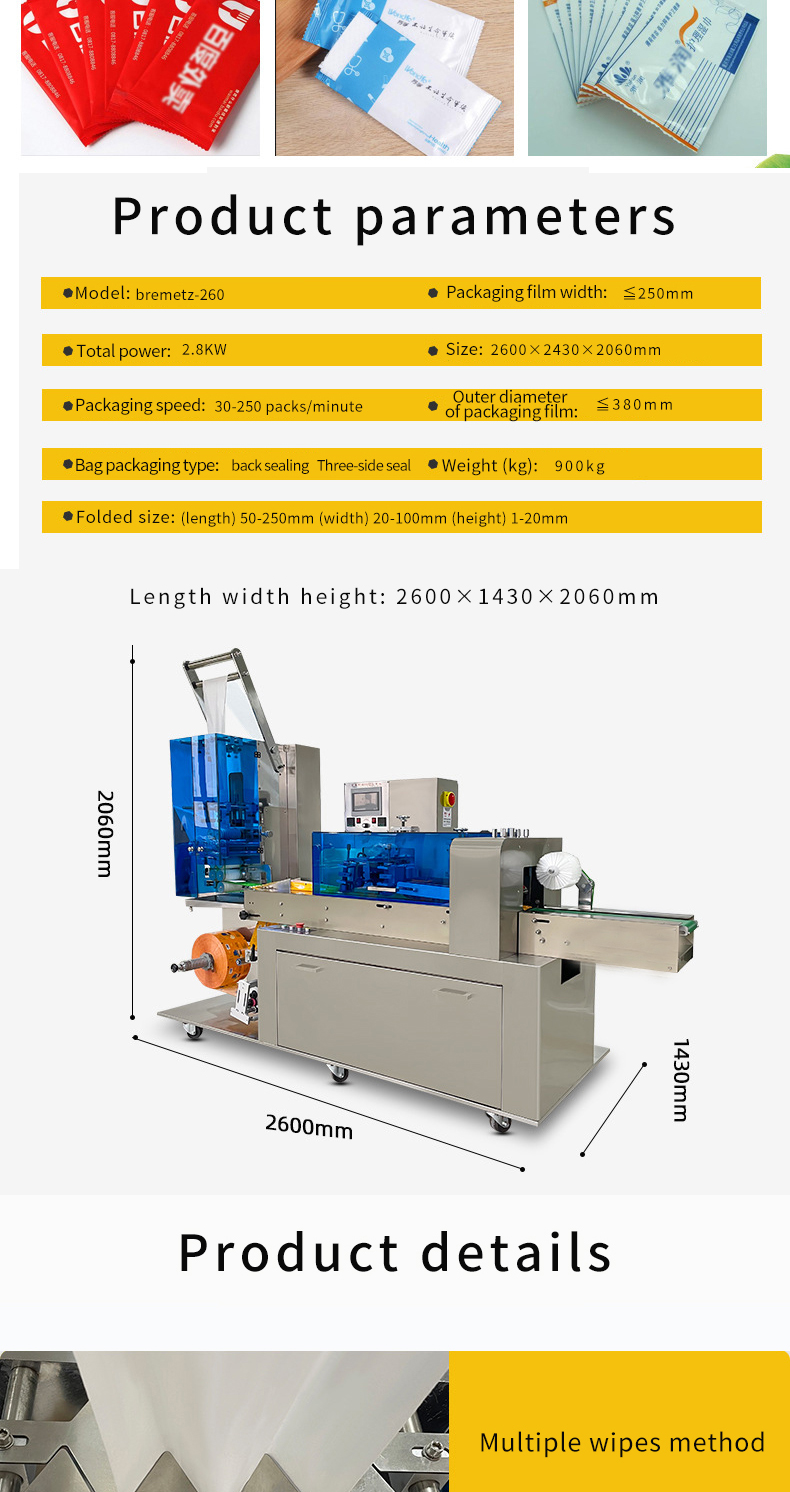

Model: bremetz-260

Packaging film width: ≤250mm

Total power: 2.8KW

Size: 2600×2430×2060mm

Packaging speed: 30-250 packs/minute

Outer diameter of packaging film: ≤380mm

Bag packaging type: back sealing Three-side seal

Weight (kg): 900kg

Folded size: (length) 50-250mm (width) 20-100mm (height) 1-20mm

Length width height: 2600×1430×2060mm

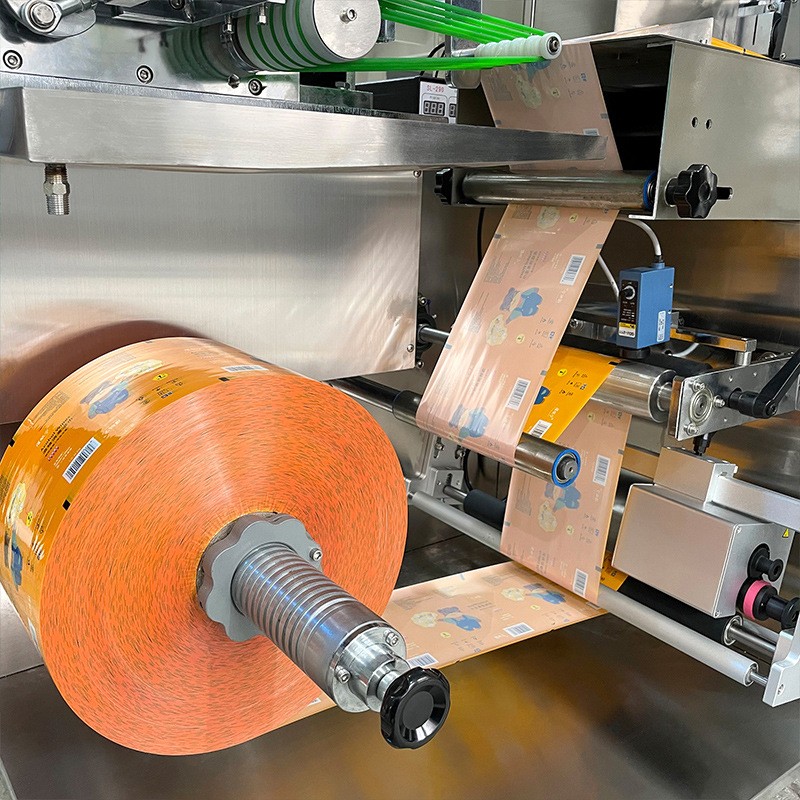

The combination of high-performance servo motors and precision transmission gears, chains or synchronous belts ensures precise synchronization of the movements of the various working parts. The servo motor has high response speed and precise position control capabilities, and can accurately adjust the conveying speed and positioning accuracy according to the instructions of the control system.

The advanced heat-sealing bag-making technology can accurately control the length, width and shape of the bag according to the preset packaging specifications. The bag-making mold is well designed and can quickly and stably form the packaging materials into various bag shapes.

With high-precision metering pumps or flow meters, the filling volume can be precisely controlled according to different wet wipe specifications and packaging requirements. The metering accuracy can reach within ±0.5%, ensuring that the liquid content in each bag of wet wipes is uniform.