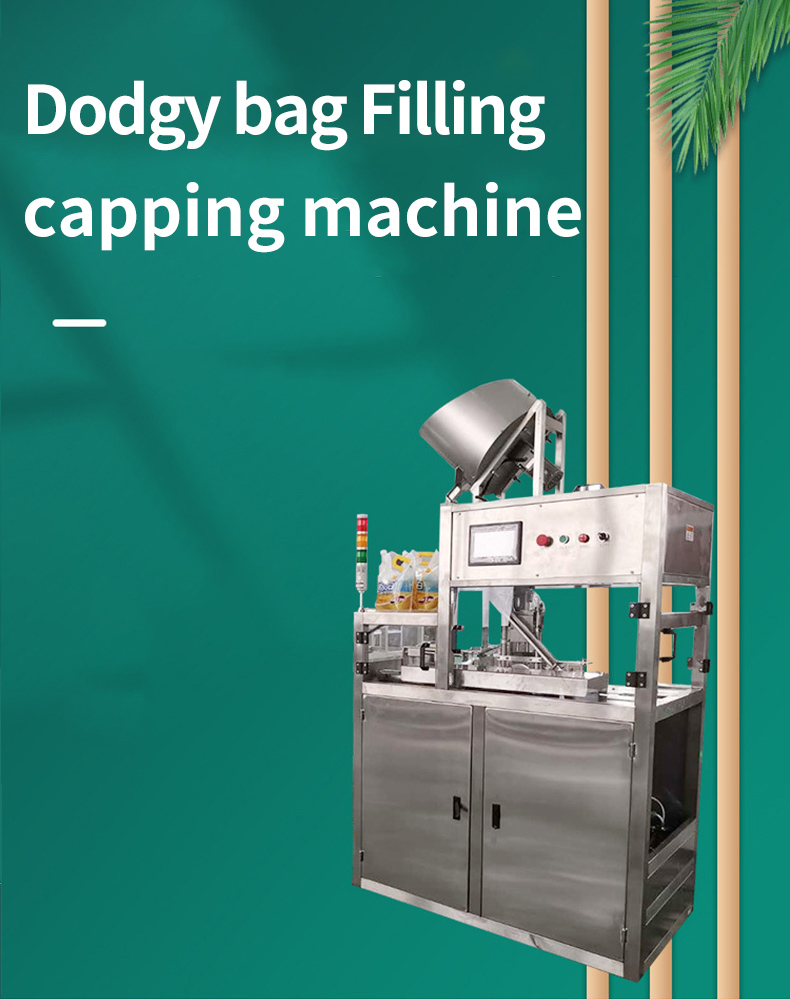

Beverage Filling Machine

Beverage Filling Machine

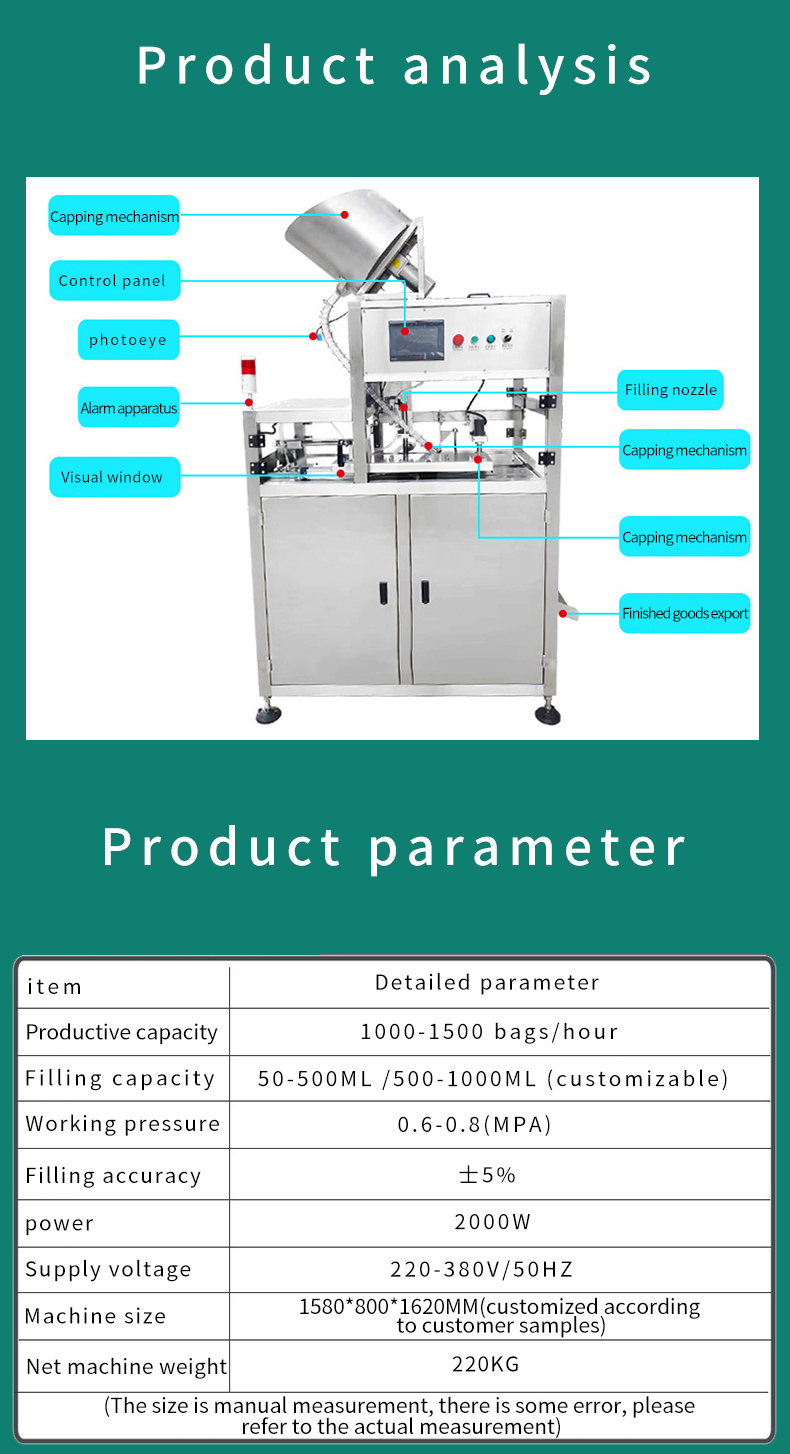

1. The machine has good structure, complete control system, easy operation and high degree of automation.

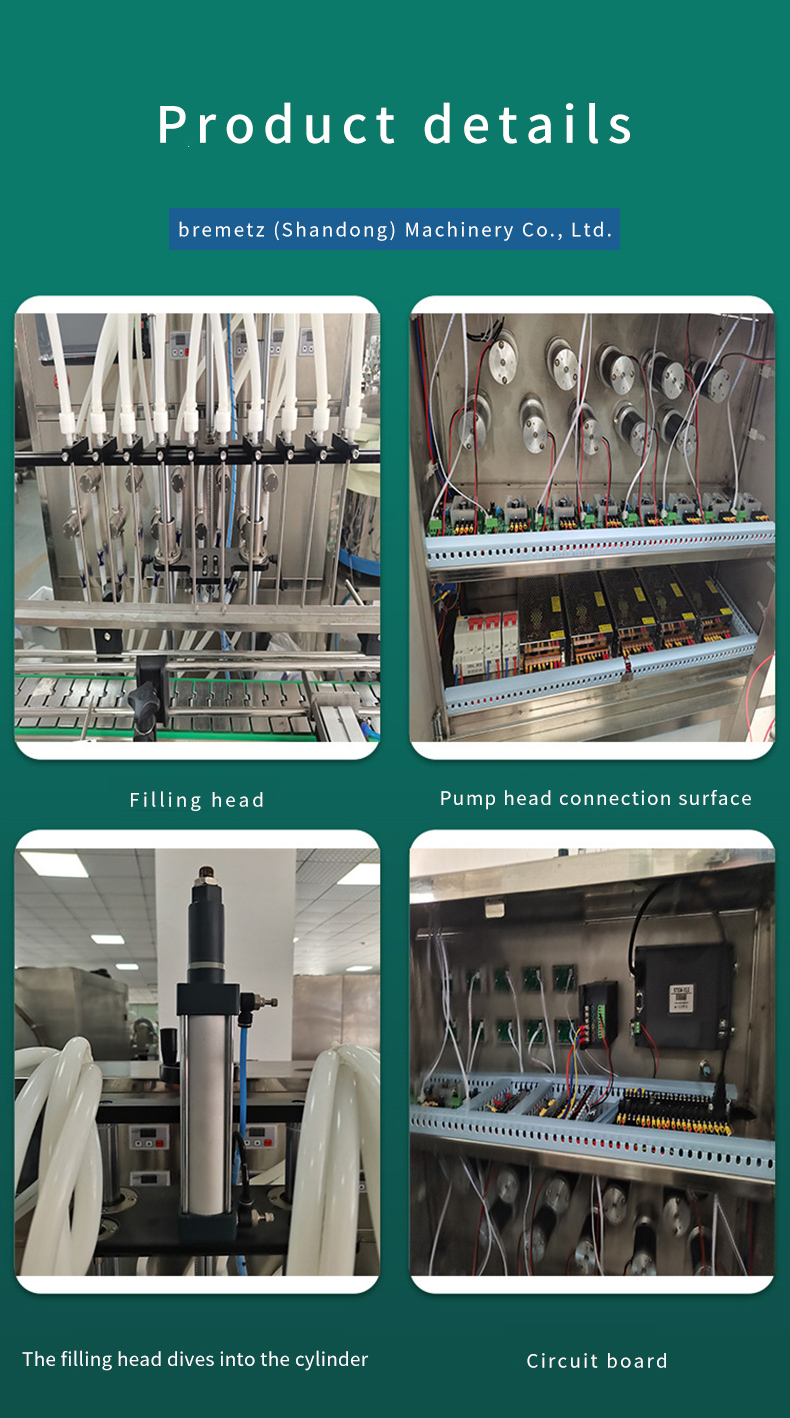

2. All parts in contact with materials are made of stainless steel, which is hygienic and easy to clean.

3. Adopt an efficient cap management system with complete cap feeding technology and protection devices.

4. Equipped with overload protection device, which can effectively protect the machinery, equipment and operators.

5. The control system has automatic control of material water level and automatic stop for stuck bottles.

6. Suspension filling is adopted, which can be used for different bottle types and thick bottles.

7. The main machine adopts frequency conversion belt control, which can easily adjust the production capacity to adapt to the speed.

8. Microelectronic data control, stable performance, making operation simple and more user-friendly.

9. The cylinder is filling power, with high productivity, simple structure and easy maintenance.

10. The screw cap part is equipped with an automatic slipping device, and the screw cap should be tightened appropriately.

11. The mixing of soda and water adopts high-intensity atomization and pressure-containing degradation at room temperature mixing methods. The ideal vapor-containing effect can be achieved without freezing.

12. Novel and unique design, filling carbonated drinks or non-carbonated drinks without interfering with each other, both can achieve ideal results.

The normal pressure filling machine fills liquid by its own weight under atmospheric pressure. This type of filling machine is divided into two types: timed filling and constant volume filling. It is only suitable for filling low-viscosity gas-free liquids such as milk, wine, purified water, juice drinks, etc.