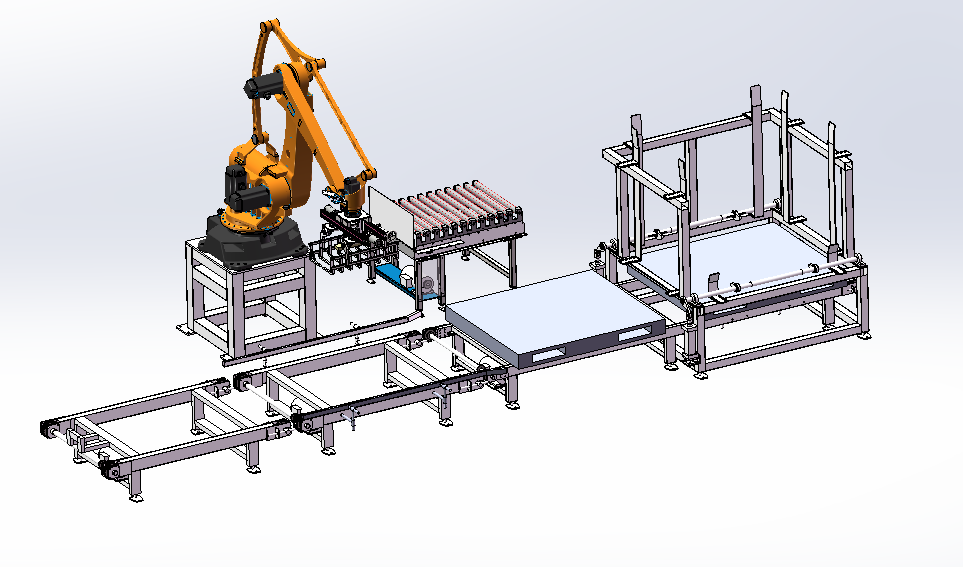

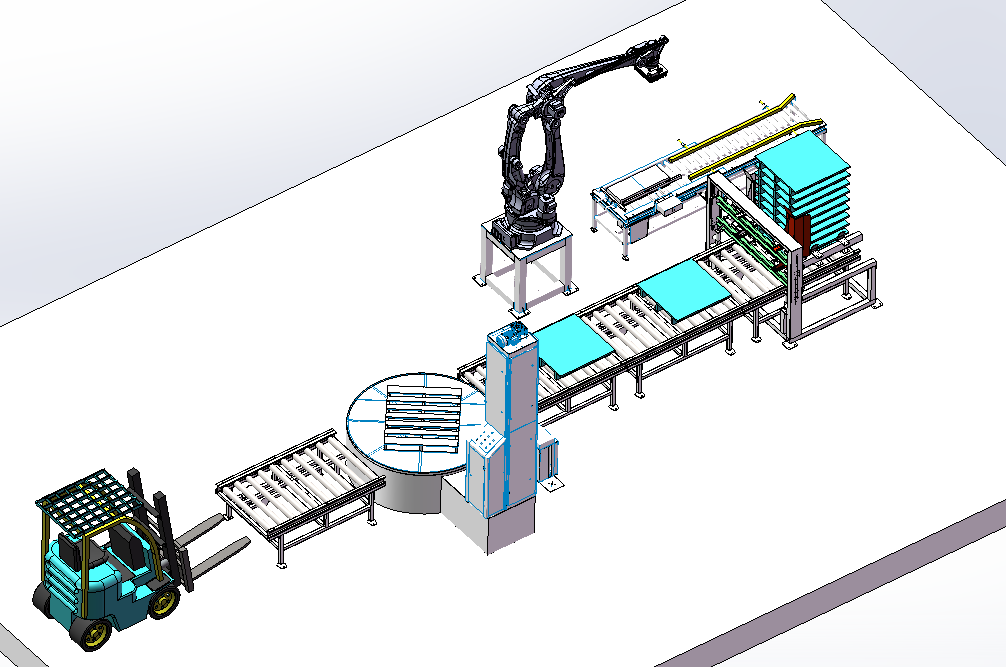

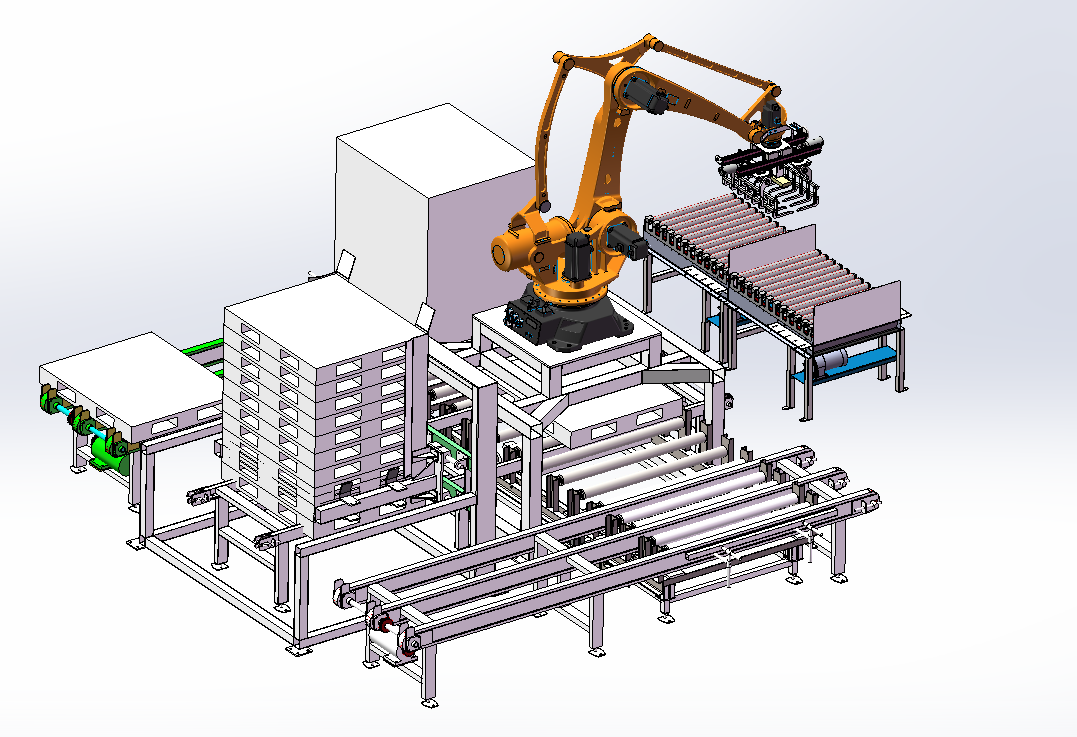

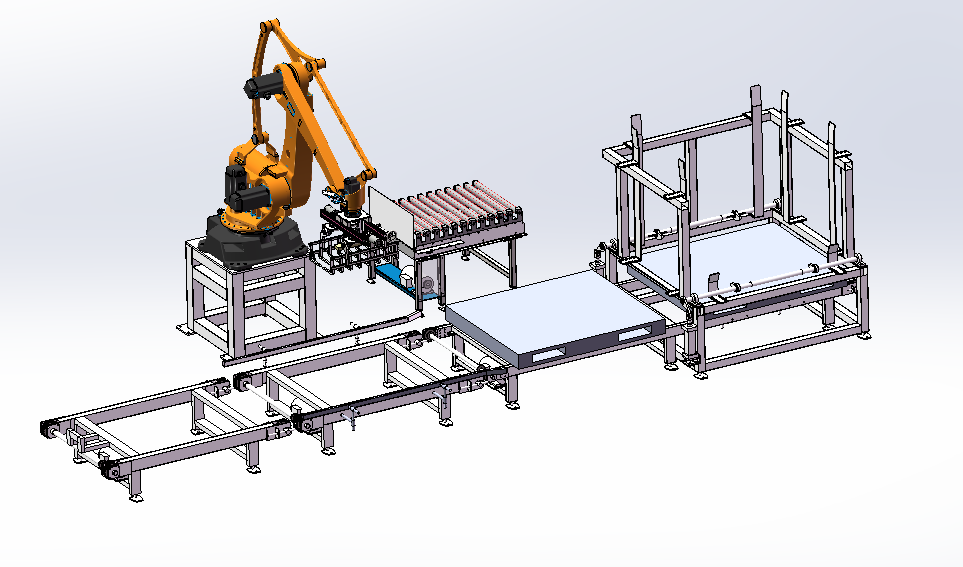

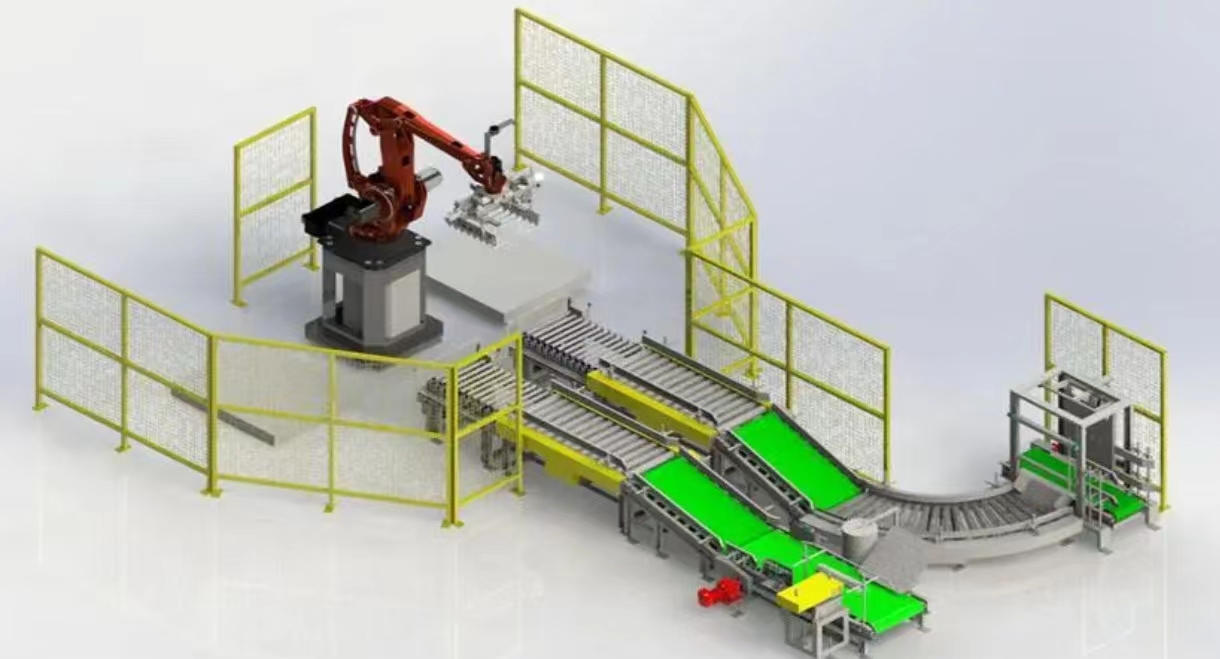

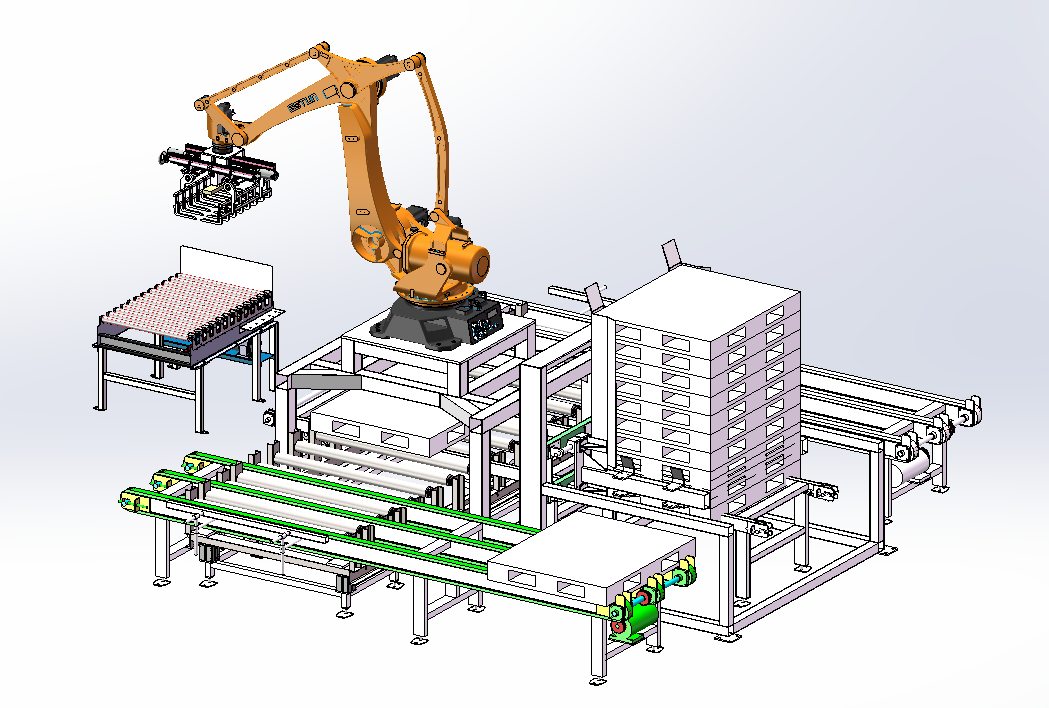

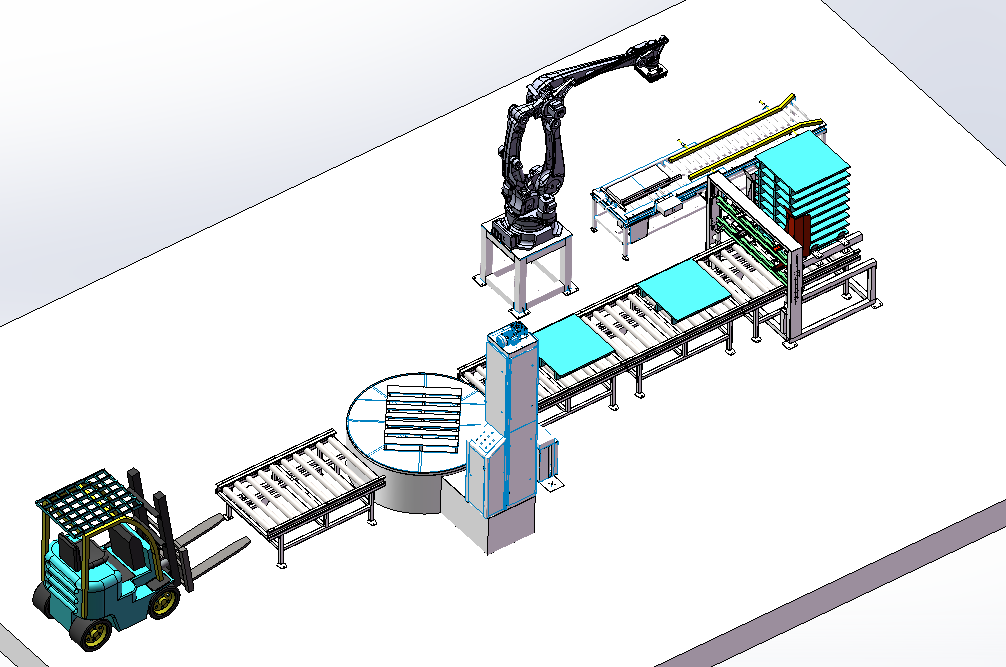

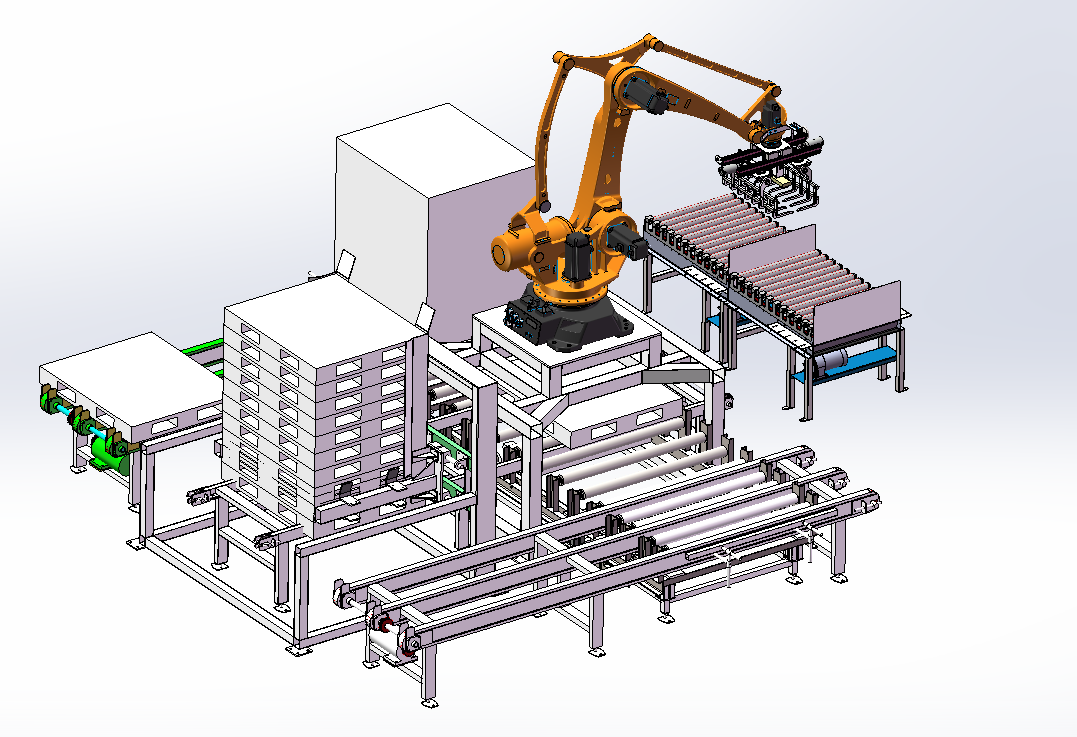

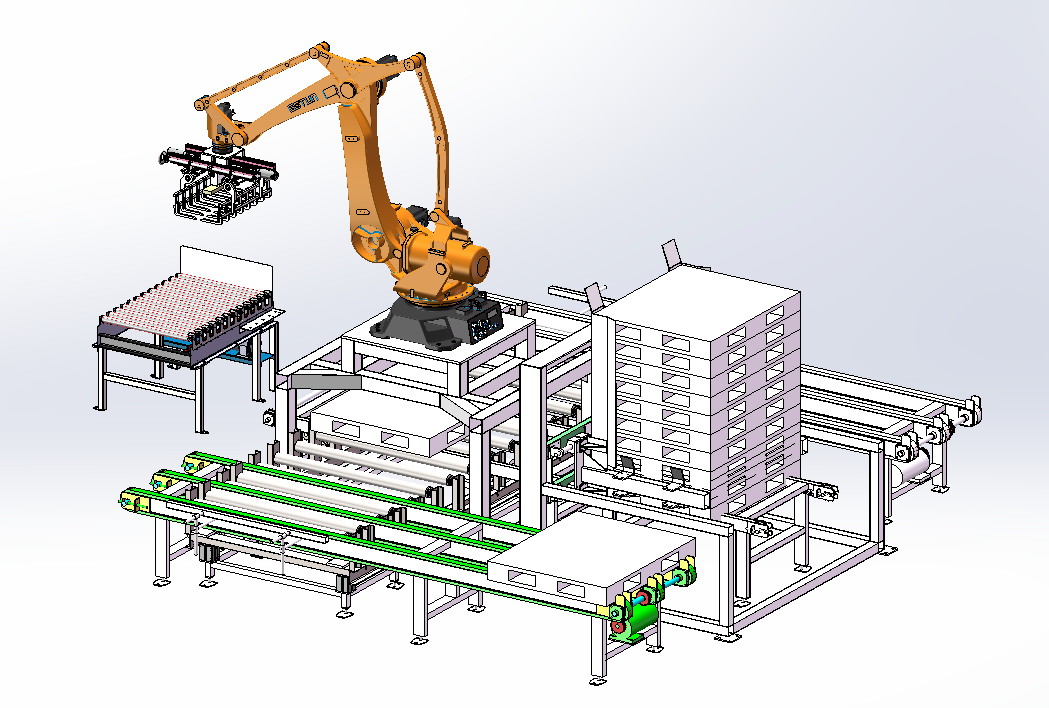

Automatic building materials packaging and palletizing production line

1. The use of advanced automation technology and high-speed mechanical parts can achieve rapid packaging and palletizing of building materials.

2. It has a high degree of stability and can run continuously for a long time, reducing production interruptions caused by factors such as equipment failure or manual operation fatigue.

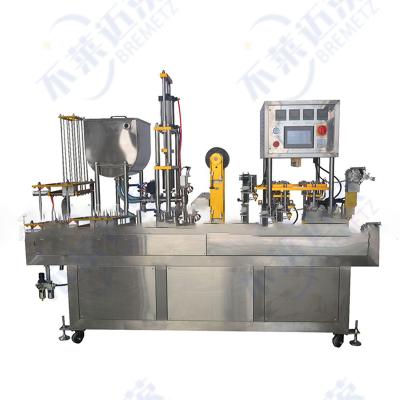

3. Equipped with high-precision metering devices, it can accurately control the packaging weight and volume of building materials to ensure that the packaging volume of each bag or piece of building materials meets the standard requirements.

4. Using advanced visual recognition systems and mechanical positioning technology, the packaged building materials can be accurately stacked on the pallet.

5. The degree of automation is high, and most links from the transportation, packaging to palletizing of building materials do not require manual intervention.

The automatic building materials packaging and palletizing production line is a highly efficient automated equipment designed for building materials manufacturers. It closely combines the packaging and palletizing of building materials, realizing a one-stop production process from finished building materials to packaging and palletizing.

The packaging measurement error is controlled within a very small range to ensure that the weight or quantity of each bag (piece) of building materials meets the standards and reduce product unqualified cases due to differences in packaging quantity.