Automatic carton robot

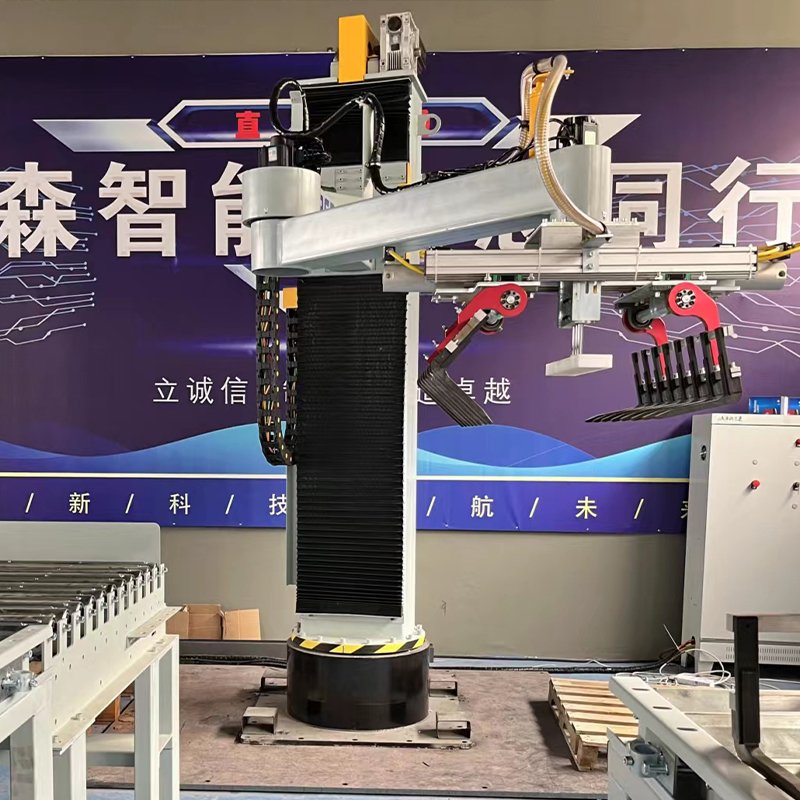

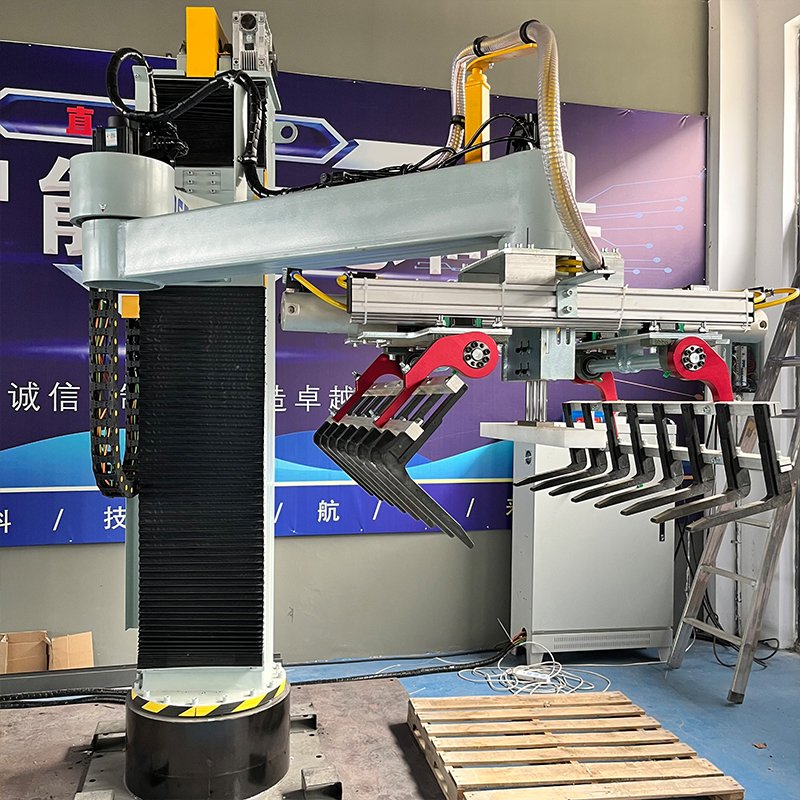

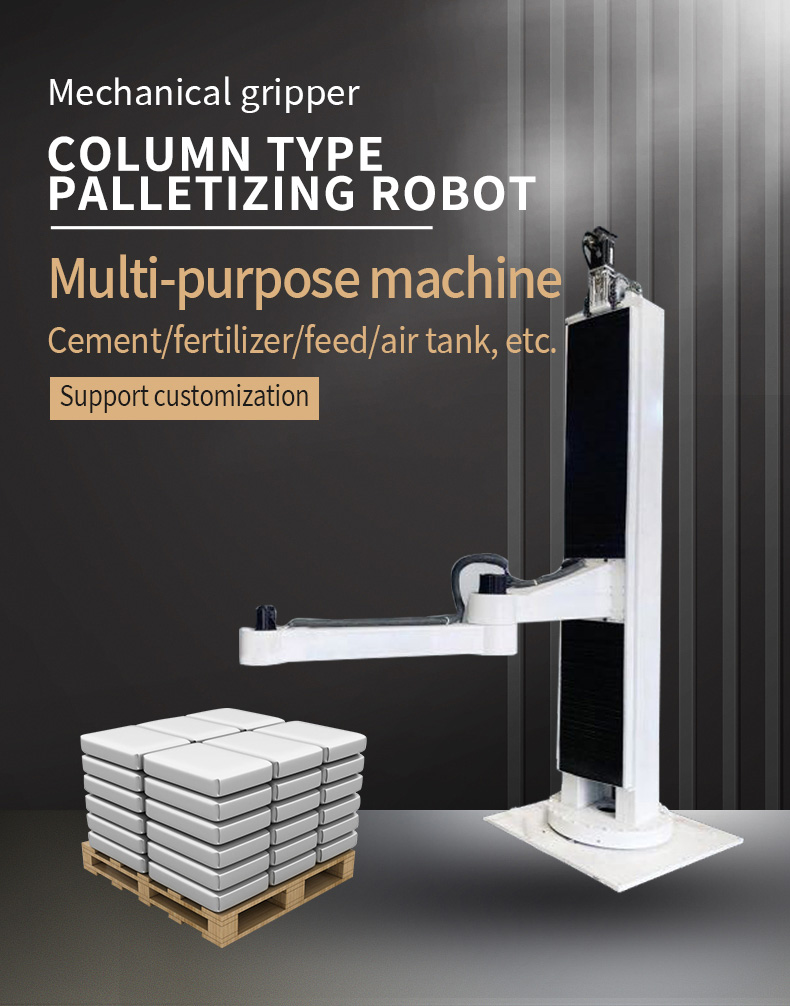

After the automatic packing machine completes the packing of the product, it enters the conveyor belt, and the product is transported to the box sealing machine, and then passes through another conveyor belt. In this conveying line, there is a positioning device, which can also be called the positioning baffle, this device and the positioning plate can complete the rotation and positioning of the box material, which can make the box material be positioned by one side, and then transported to the buffer zone, and the stacking robot is above the buffer zone. The robot lifts the whole container material vertically through the manipulator and then runs horizontally to avoid the safety channel. After passing through the safety channel, it is placed vertically in the palletizing area. After the placement is completed, it returns according to the original path.

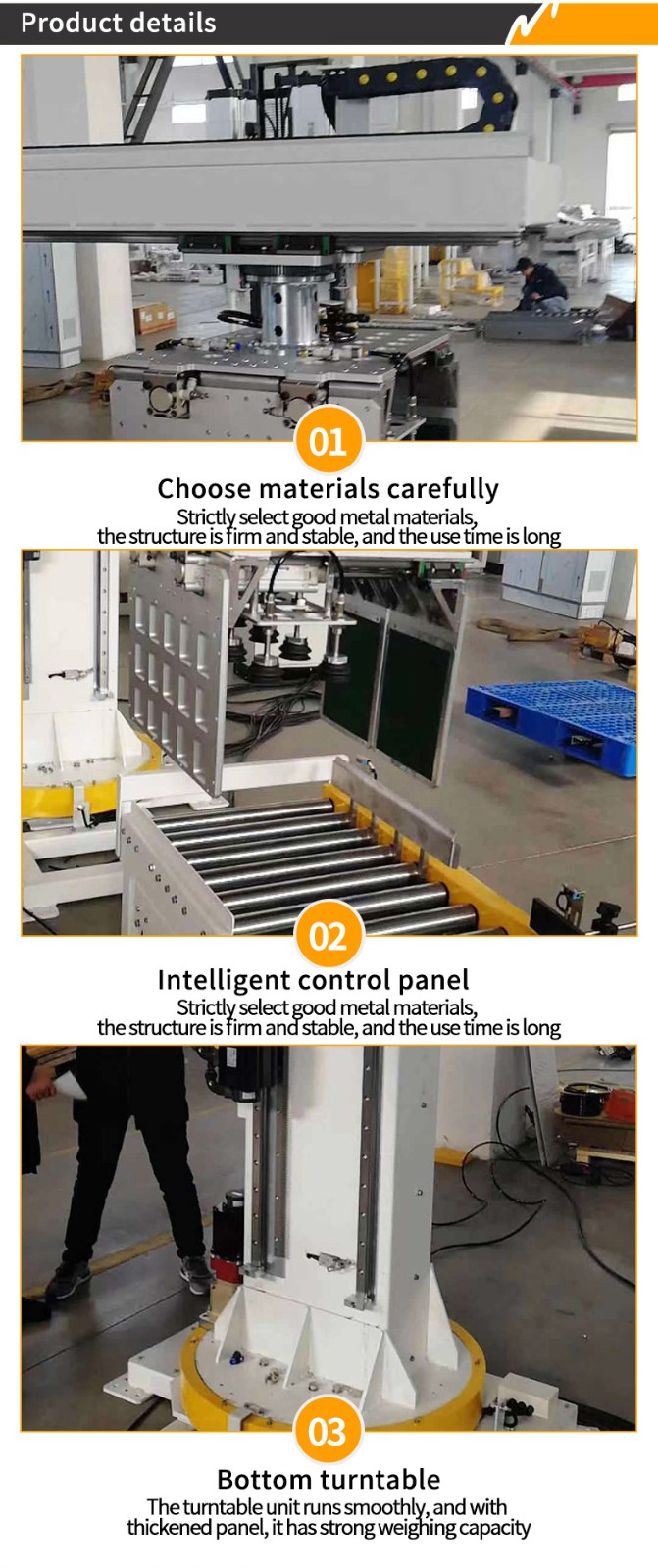

Intelligent packing and palletizing system can complete the product packaging, heavy lifting, handling, flipping, docking, fine-tuning Angle and other three-dimensional space load movement, providing ideal handling and assembly tools for product line assembly. The loading and unloading intelligent palletizing manipulator not only reduces the labor intensity of the operation to provide safe material handling, but also provides system solutions for special environments such as explosion-proof workshops and dangerous places where personnel cannot enter. With a variety of non-standard fixtures, the manipulator can realize the lifting of various shapes of the workpiece, so that the load reaches a zero-gravity floating state, the operator can easily take off and land the load, move, rotate, tilt forward and roll over. And the load is quickly and accurately placed in the pre-set position, using it a person can easily operate the original large number of manually moved items.