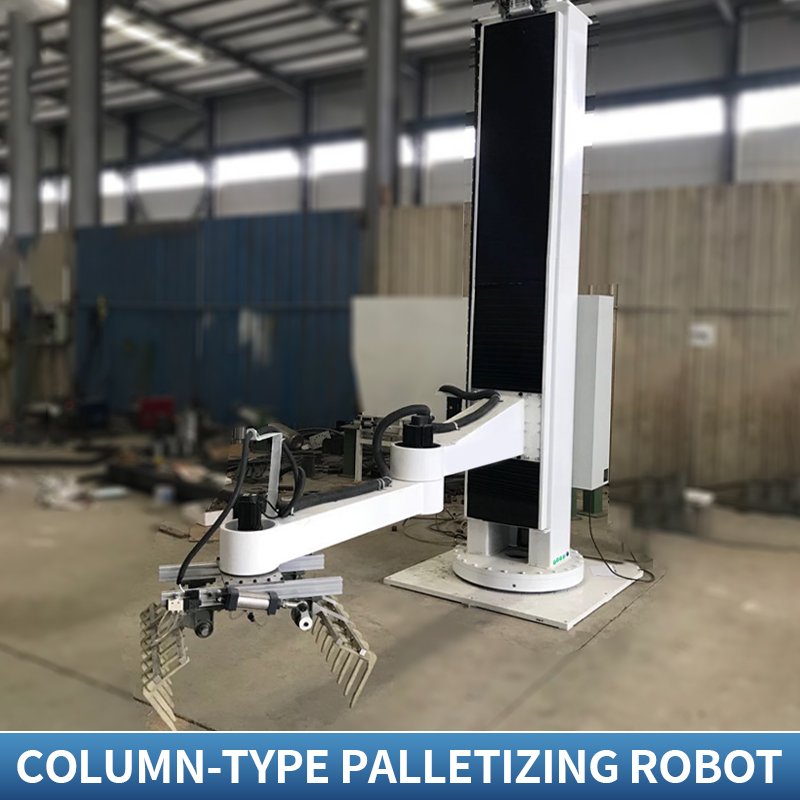

Working principle of the corrugated paper column palletizing robot

The corrugated paper column palletizing robot is an automated equipment specially used for palletizing of corrugated paper products.Working principle: Positioning and identification: First, the packaged corrugated paper is transported to the designated palletizing area by the conveyor for positioning. The robot is equipped with sensors, such as visual sensors or laser sensors, which detect the position, shape, size and other information of the corrugated paper to provide accurate data for subsequent grasping actions.Grasping and handling: When the material positioning signal is received, the robot's column structure drives the mechanical arm to move so that the clamp runs directly above the material. Then, the clamp moves downward in the vertical direction (z axis) through the control of the servo motor. After reaching the appropriate clamping height, the clamp opens to clamp the material. Subsequently, the z-axis servo motor reverses and raises the clamp to a safe height.Palletizing operation: The robot moves the clamped corrugated paper to the top of the palletizing position according to the preset program and pallet type requirements. The z axis drops again so that the material reaches the placement point. At this time, the clamp opens and the corrugated paper is stacked at the designated position. Repeat the above steps until the whole pallet is stacked.