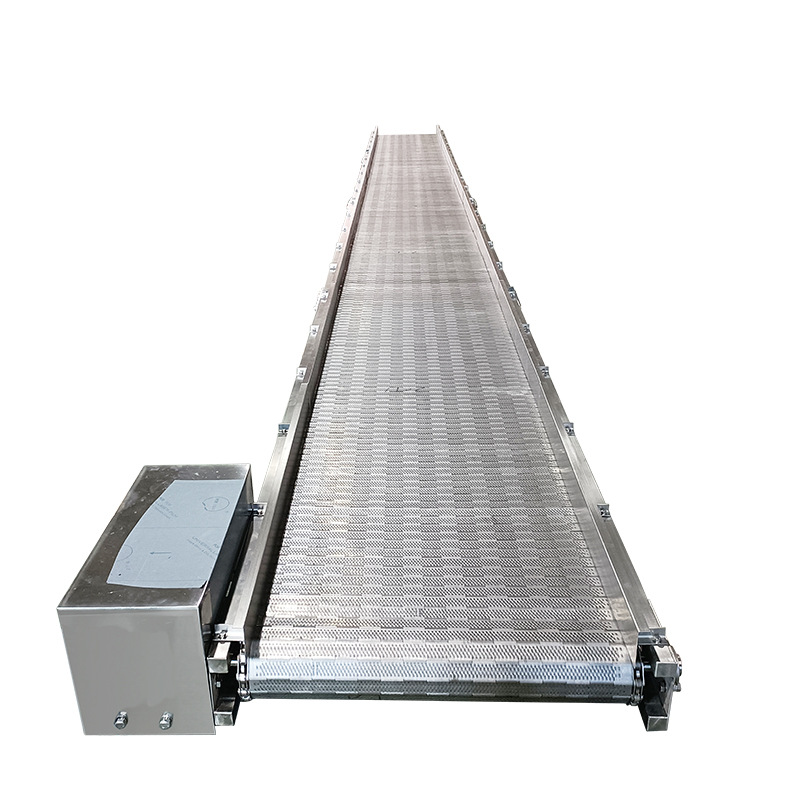

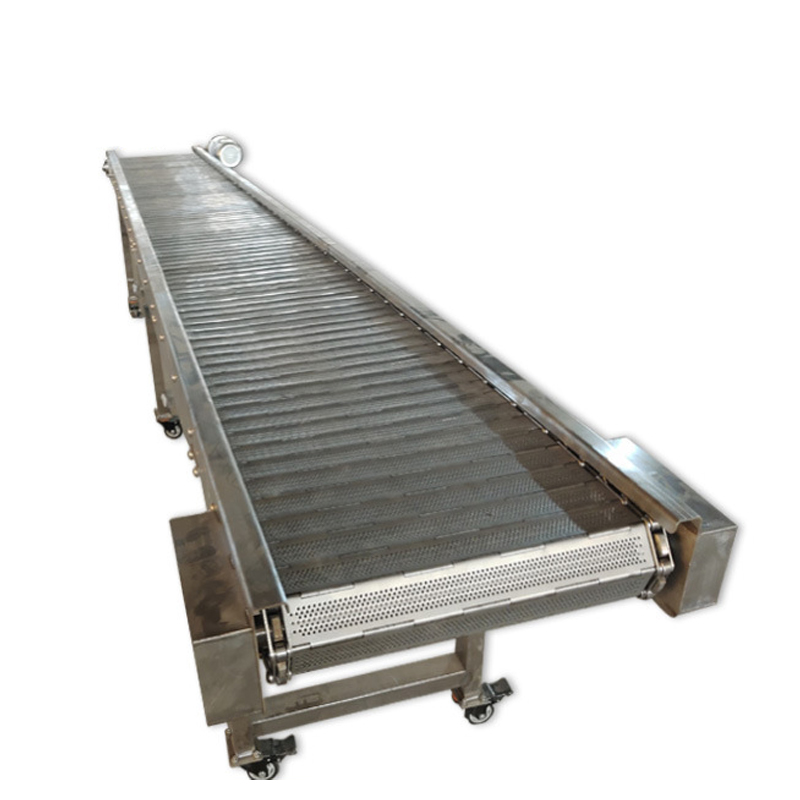

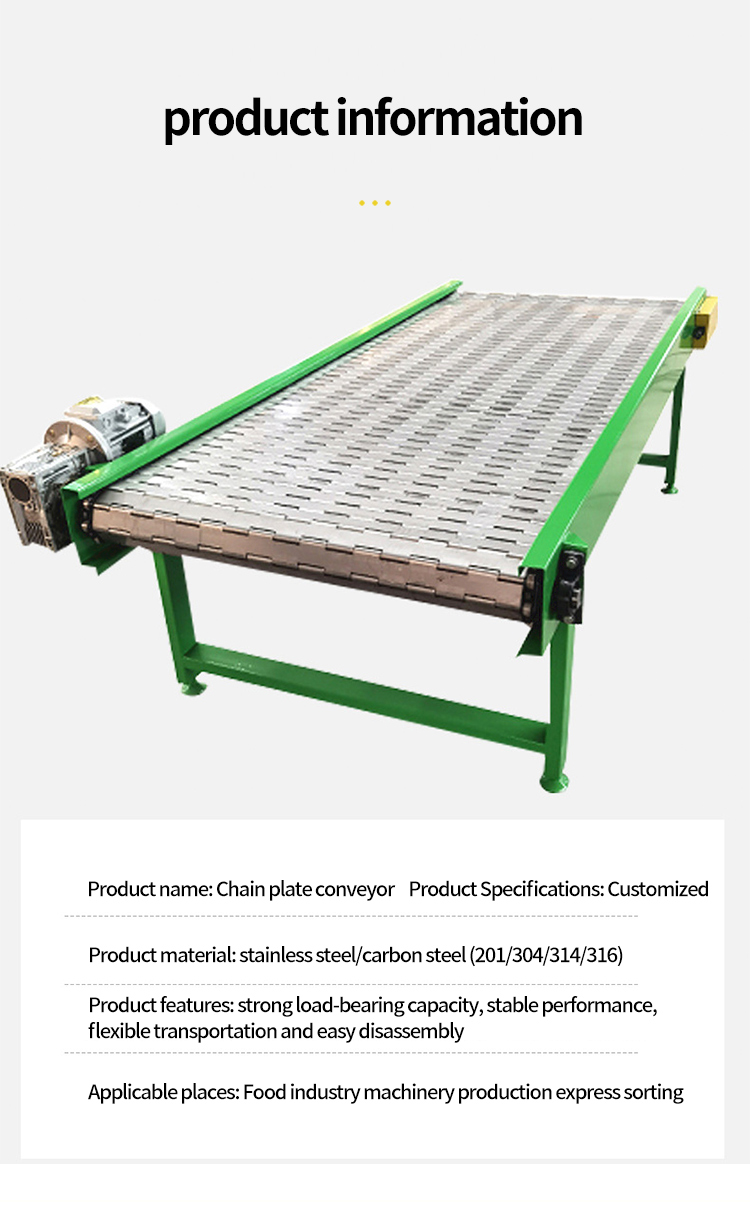

Chain Conveyer

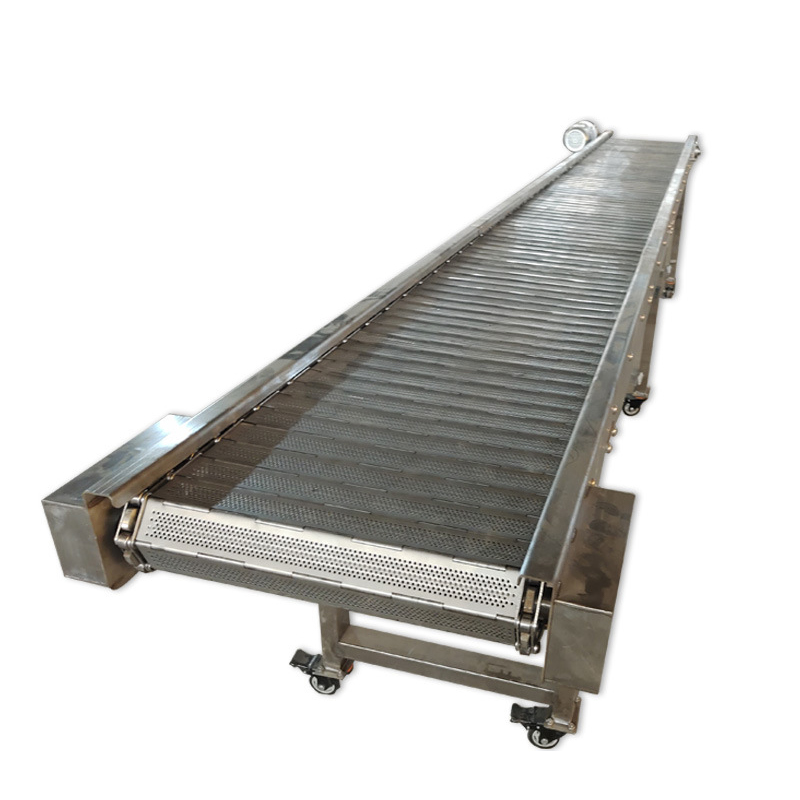

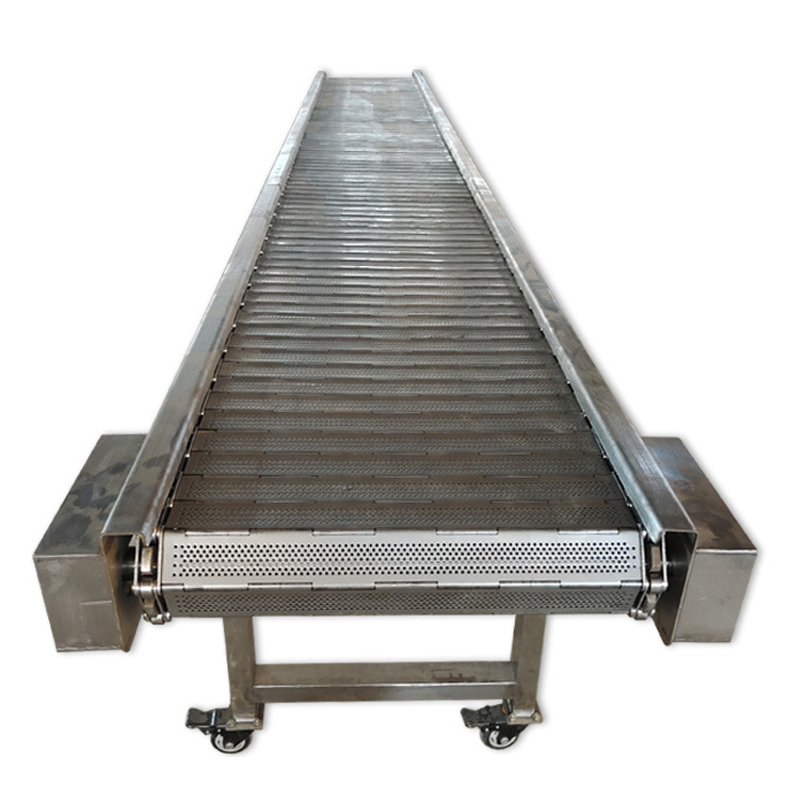

1. The conveying surface of the chain conveyor is flat and smooth, with low friction, and the material transitions smoothly between conveying lines. It can convey various types of glass bottles, PET bottles, cans and other materials, as well as various types of luggage;

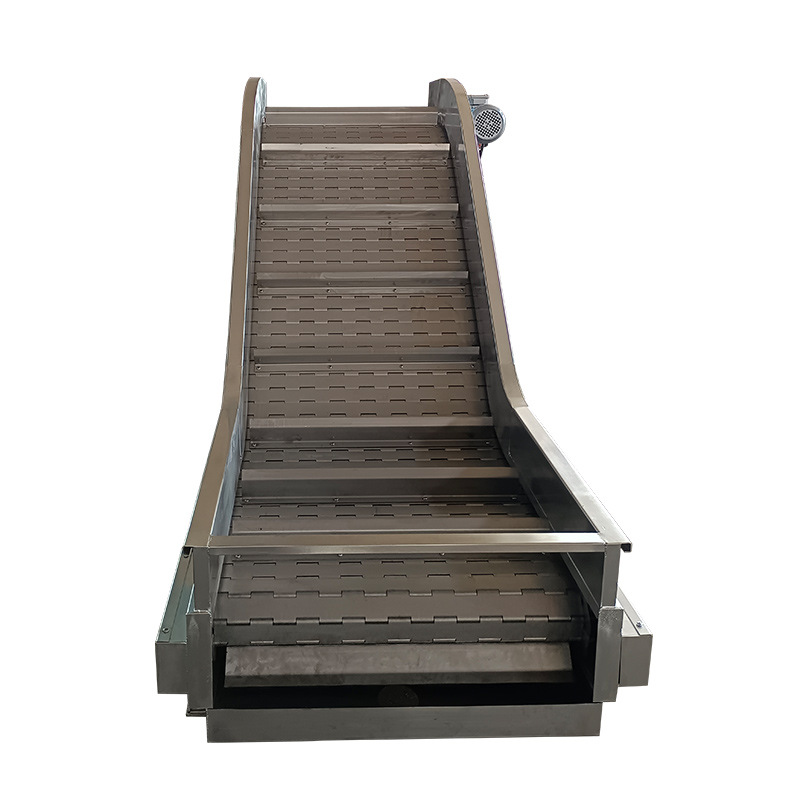

2. The chain plates are made of stainless steel, engineering plastics and other materials and have a wide variety of specifications. They can be selected according to the conveyed materials and process requirements, and can meet the different needs of various industries;

3. The frame material is divided into aluminum profiles, ordinary carbon steel, and stainless steel.

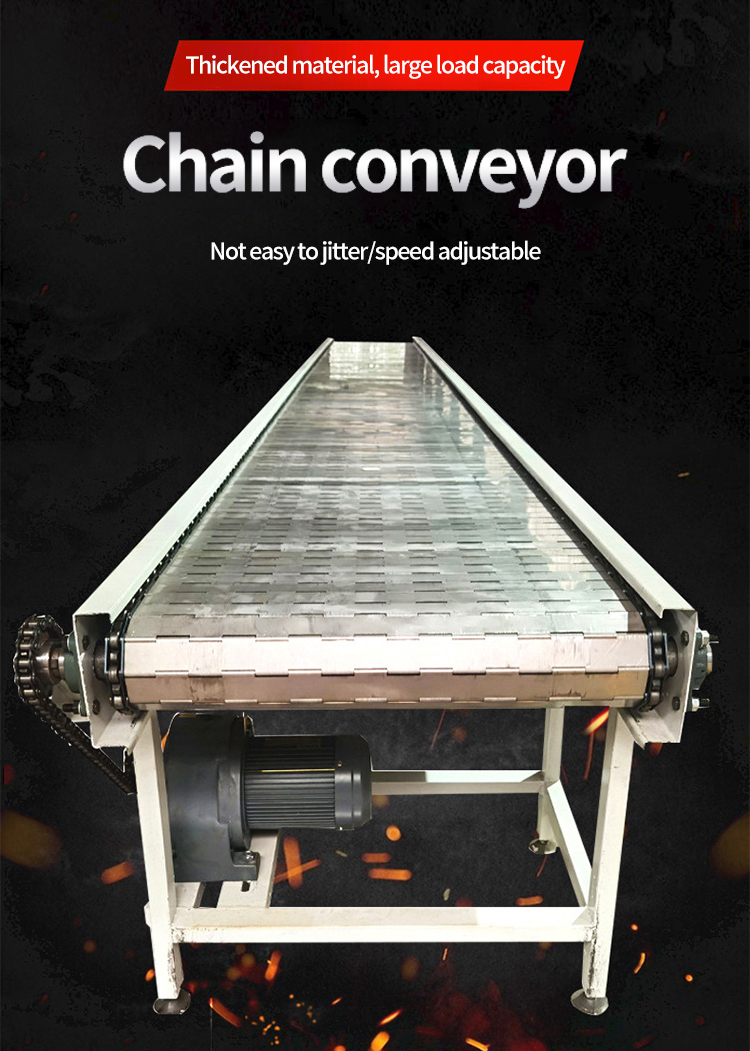

4. It has large conveying capacity and can carry larger loads, such as used in electric vehicles, motorcycles, generators and other industries;

5. The conveying speed is accurate and stable, ensuring precise synchronous conveying;

6. Chain conveyors can generally be washed directly with water or soaked in water. The equipment is easy to clean and can meet the hygiene requirements of the food and beverage industry;

7. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line;

8. The equipment has a simple structure and is easy to maintain.