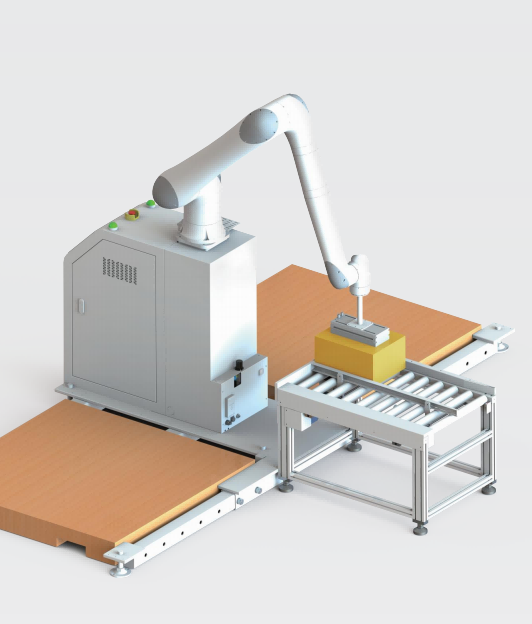

Collaborative palletizing robot

1. It can run 24 hours a day without rest or vacation, which can effectively increase production time and improve overall output.

2. With advanced sensors and intelligent design, it works fast and accurately, which can greatly reduce the palletizing time.

3. It can undertake palletizing work with high repetitiveness and labor intensity, so that enterprises can reduce their dependence on manpower

4. It has high operating accuracy and can avoid problems such as wrong placement and unevenness of goods that may occur during manual palletizing.

5. The palletizing mode, pallet type and cargo type can be quickly adjusted through simple programming to easily meet the palletizing needs of different products.

Collaborative palletizing robots are an important innovation in the field of industrial automation, aiming to provide modern enterprises with efficient, precise, safe and flexible palletizing solutions.

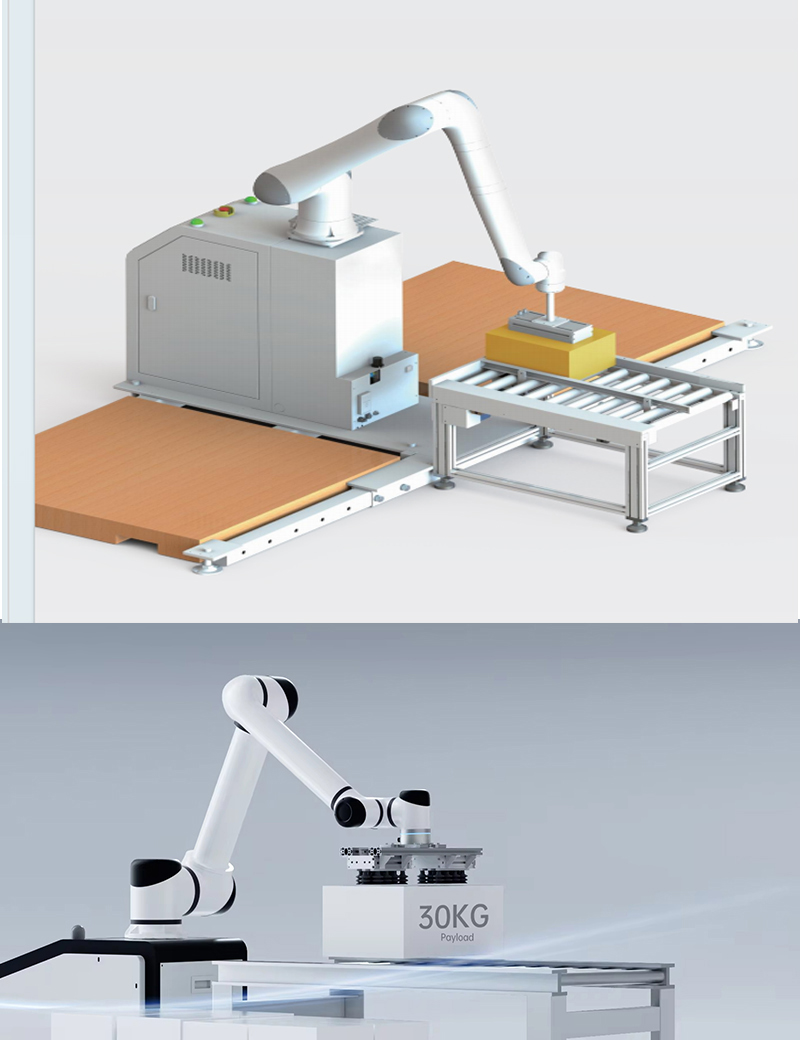

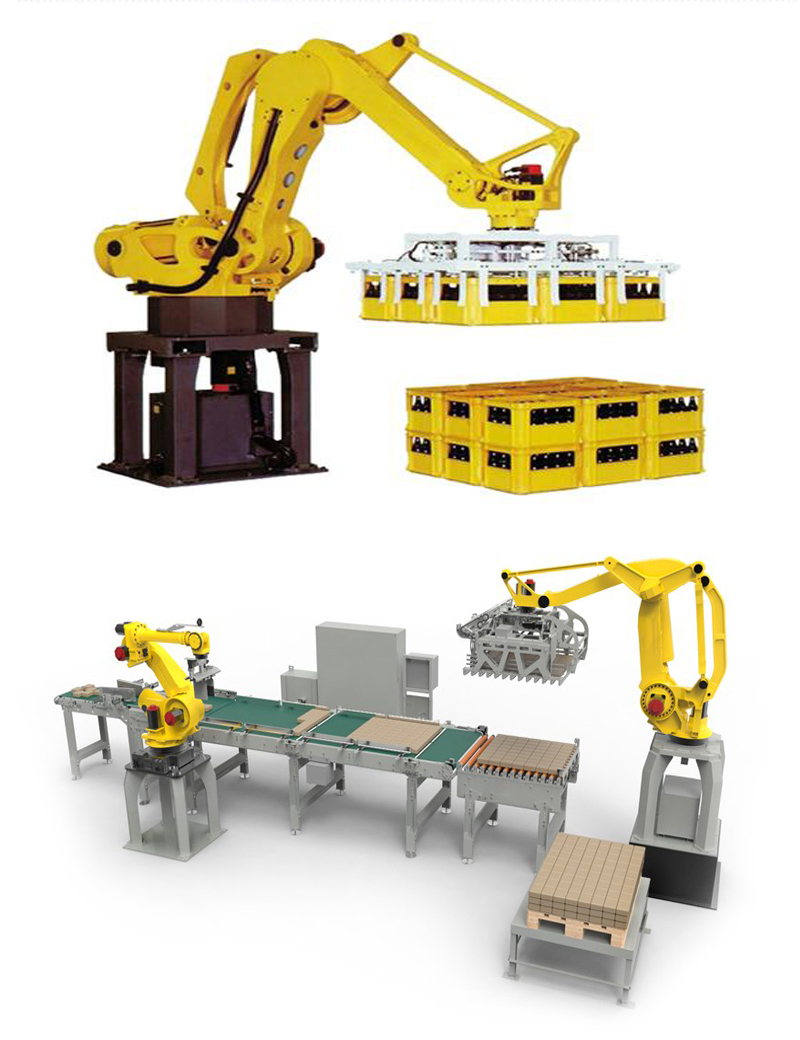

Equipped with high-resolution industrial cameras and advanced visual processing algorithms, collaborative palletizing robots can quickly and accurately identify and locate goods on the conveyor belt or in the work area in an instant.

Using advanced force feedback and collision detection technology, the collaborative palletizing robot can sense the contact force and collision between the robot arm and surrounding objects in real time, and automatically respond according to the preset safety strategy.

Based on advanced artificial intelligence and machine learning technologies, the collaborative palletizing robot has a built-in intelligent palletizing algorithm that can automatically plan the optimal palletizing plan and pallet type based on the parameters of the goods.

It supports remote monitoring and diagnosis functions. Managers can remotely monitor and manage the working status, operating parameters, task progress, etc. of the collaborative palletizing robot in real time through the network.

Equipped with a variety of end effectors and advanced visual recognition systems, collaborative palletizing robots can adapt to the palletizing needs of goods of various shapes, sizes, weights and materials.