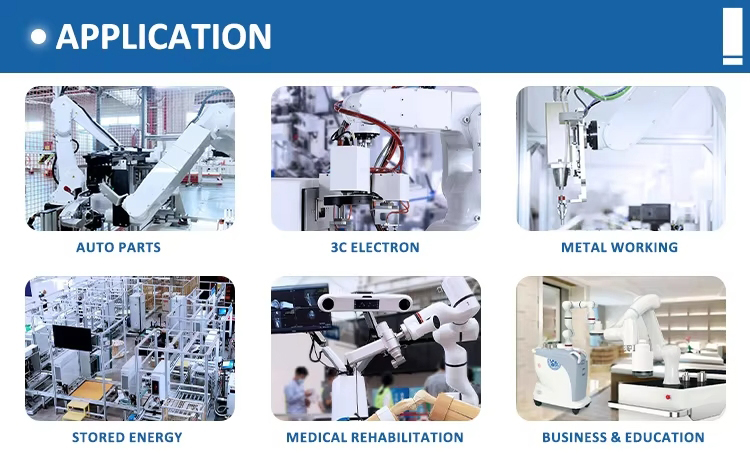

Collaborative Robot Arm Articulated Metal Laser Welding Machine

It is widely used in high-quality, high-precision welding of various workpieces with rotating shafts, and is suitable for power, electrical, mechanical, automotive and other industries. If manual arc welding is used for rotating shaft welding, the labor intensity of workers is extremely high, the consistency of products is poor, and the production efficiency is low, only 2-3 pieces/hour. After using automatic welding workstations, the output can reach 15-20 pieces/hour, and the welding quality and product consistency are also greatly improved.

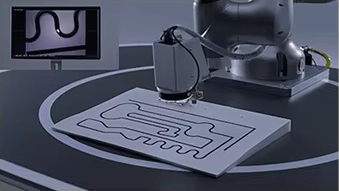

Collaborative welding robots are usually equipped with advanced sensors and camera systems that can monitor the surrounding environment in real time and adjust welding posture and strength according to actual conditions. This type of robot also has a lightweight design and agile movement capabilities, which can flexibly adapt to different work scenarios and needs.

Parameters of collaborative welding robot

Planning of collaborative welding robot: graphical human-machine interface, 12-inch touch screen, TCP/IP script programming CC++ programming language Axis range of collaborative welding robot: +180°

Degrees of freedom of collaborative welding robot: 6 rotary joints

Material of collaborative welding robot: aluminum ABS

Communication interface of collaborative welding robot: TCP/IP 100Mit, ModbusTCP

Power consumption of collaborative welding robot: 220V AC 50Hz

Excellent performance and efficiency first

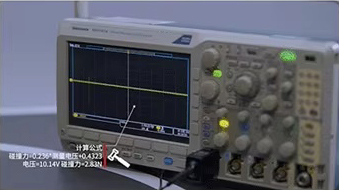

The repetition accuracy is better than 0.03mm

Track speed increased by 20%

Increased service life by 30%

ROl< 6 months

Full manufacturing quality assurance

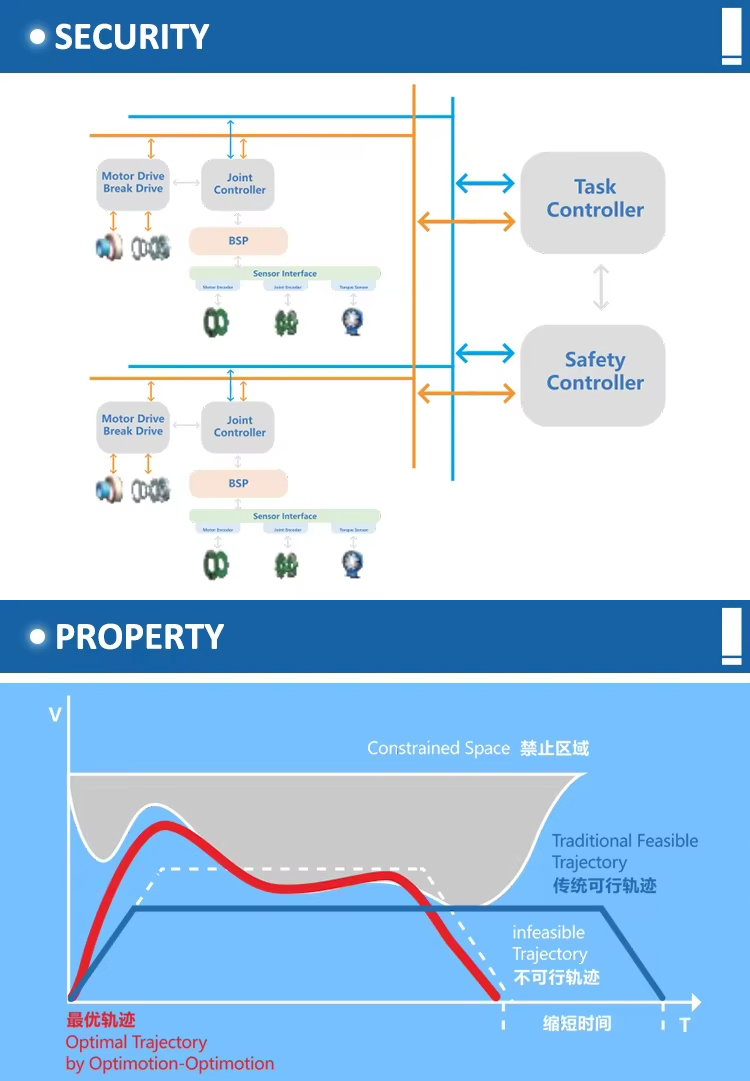

Ultimate safety and comprehensive protection

5 times greater collision sensitivity

>22 TUV functional safety certifications

Suction lock, reliabie safety barrier

No control cabinet, system weight reduction by 50%

1N Light drag, directly teach programming

Graphical operation interface, 1 hour to master the

operation

Flexible production line deployment reduces

integration costs by 30%

Efficient protection · Stable and reliable

lP67 protection grade, leading in the industry

200+ dynamic parameter modeling, effectively

prevent small horse and big car

The life of the motor reducer is effectively increased

by 30%