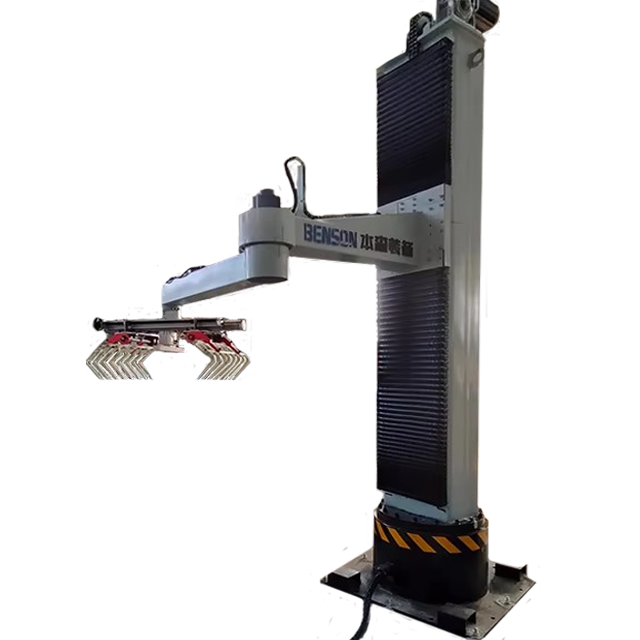

Multifunctional column robot

1. It can work uninterruptedly for a long time without being affected by factors such as fatigue, which can greatly improve production efficiency.

2. It adopts advanced control system and sensor technology, with accurate motion control and high repeat positioning accuracy.

3. It can replace a large number of manual operations and reduce the company's investment in manpower.

4. It usually has good stability and reliability, solid structure, few main components and low failure rate.

5. It can adapt to materials of different sizes, shapes and weights through programming and replacement of fixtures.

6. It can be customized and configured according to different production tasks and process flows to achieve multiple functions.

Multifunctional Column Robot is an automated mechanical equipment that uses columns as support structures, combined with advanced robotic arms, control systems and various sensors. It has multiple functions and can be widely used in industrial production, logistics warehousing and other fields.

Load capacity: Generally between 10 - 500 kg. The load capacity of multi-functional column robots of different models and configurations varies.

Palletizer name and model:STEVEN120 - 2400

Movement degrees of freedom (axis):4

Maximum load capacity (kg):120

Repeat positioning accuracy (mm):±0.3mm

Drive mode:Servo drive

Vehicle:Fixture

Palletizing memory:Intelligent memory

Maximum coverage:2350

Body weight:1025

Installation method:Ground

Repeatability: ±0.1 - ±1 mm. High repeatability ensures that the robot can maintain high consistency and accuracy when performing the same task multiple times.

Movement speed: The joint movement speed of the robot arm is generally between 1 and 3 meters per second, and the linear movement speed can reach 2 to 5 meters per second. Faster movement speed helps improve the robot's work efficiency.

Scope of application

Industrial manufacturing: used for handling, assembly, welding and other work of parts in automobile manufacturing, mechanical processing, electronic and electrical industries.

Logistics and warehousing industry: suitable for palletizing, sorting, and handling of goods in warehouses.

Agricultural production: can be used for picking, packaging, and handling of agricultural products.

Food and beverage industry: used for handling food raw materials, packaging and palletizing of finished products in food processing workshops.