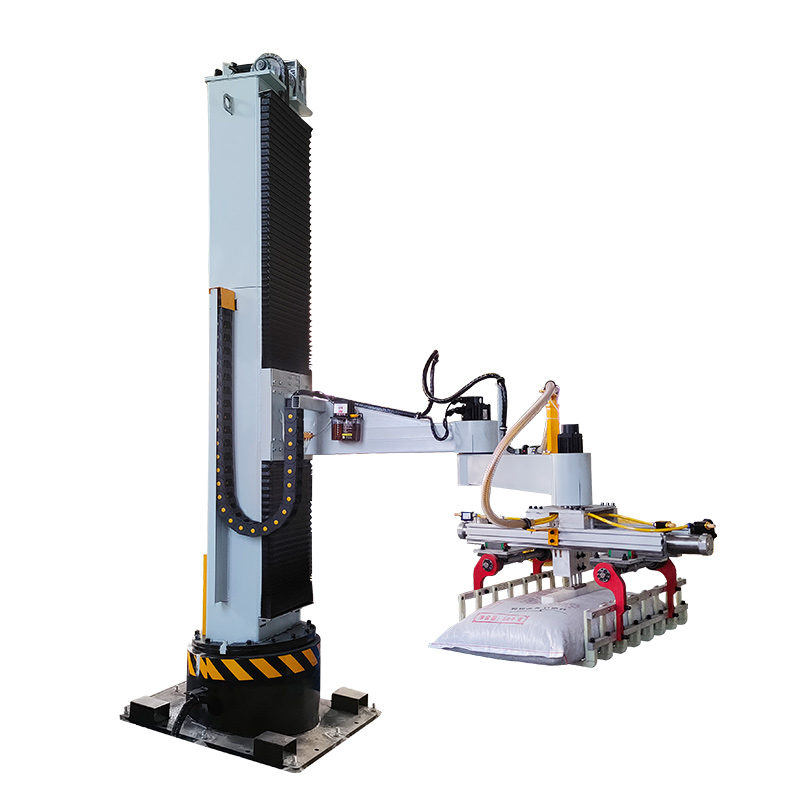

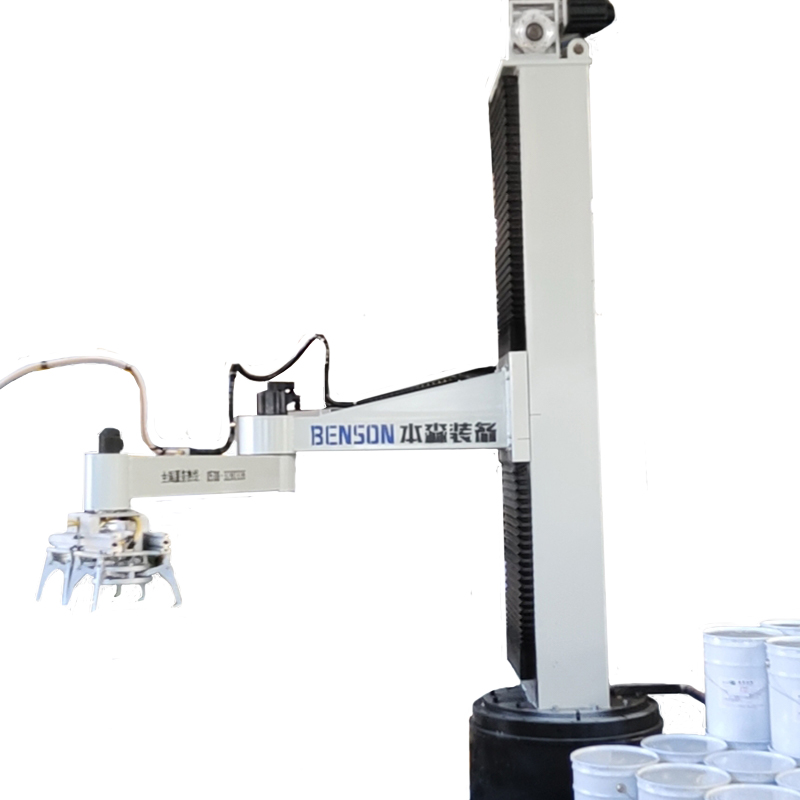

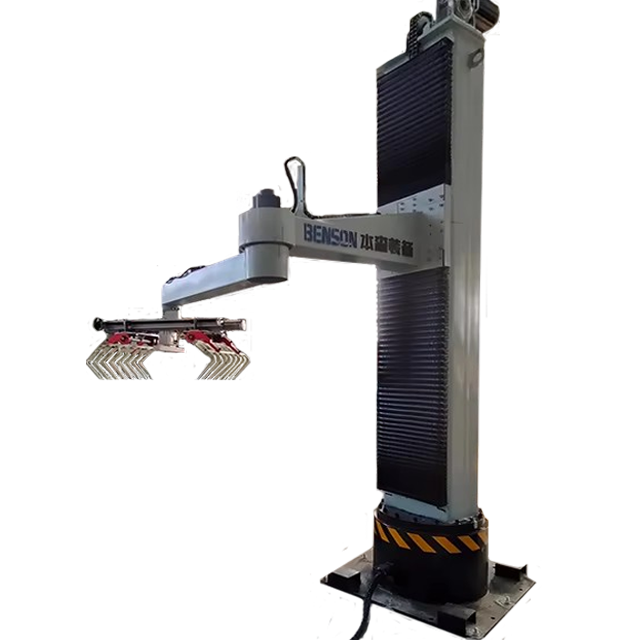

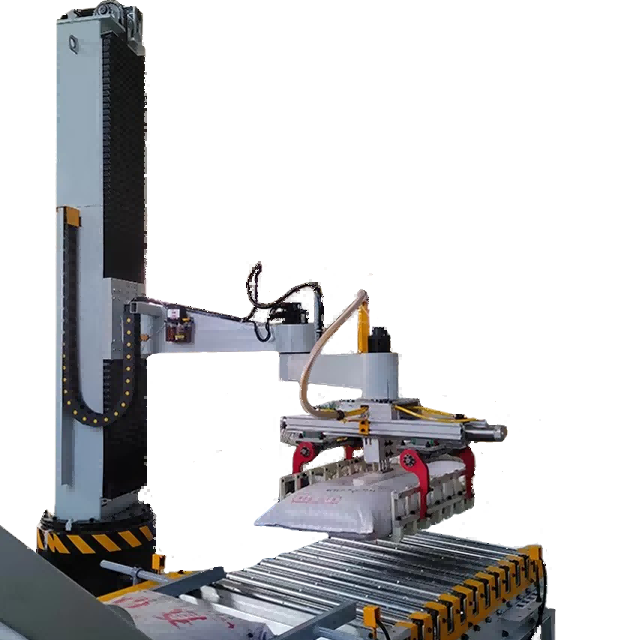

Automatic column robot

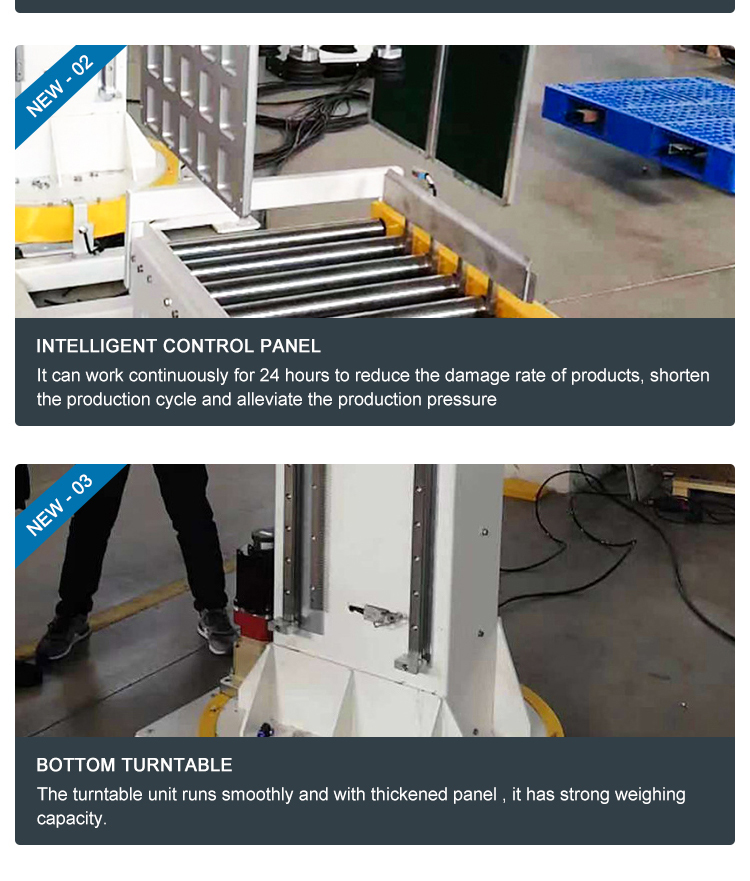

1. The column design is more compact, which can effectively utilize vertical space and reduce the occupation of ground space.

2. It can be flexibly configured on different production lines, and it is easier to coordinate with the layout of peripheral equipment.

3. Through high-precision servo motors, advanced control systems and precise mechanical structures, precise positioning and operation can be achieved, and materials can be accurately grasped and placed.

4. The high-strength and high-rigidity mechanical structure can withstand large loads and pressures and remain stable during long-term operation.

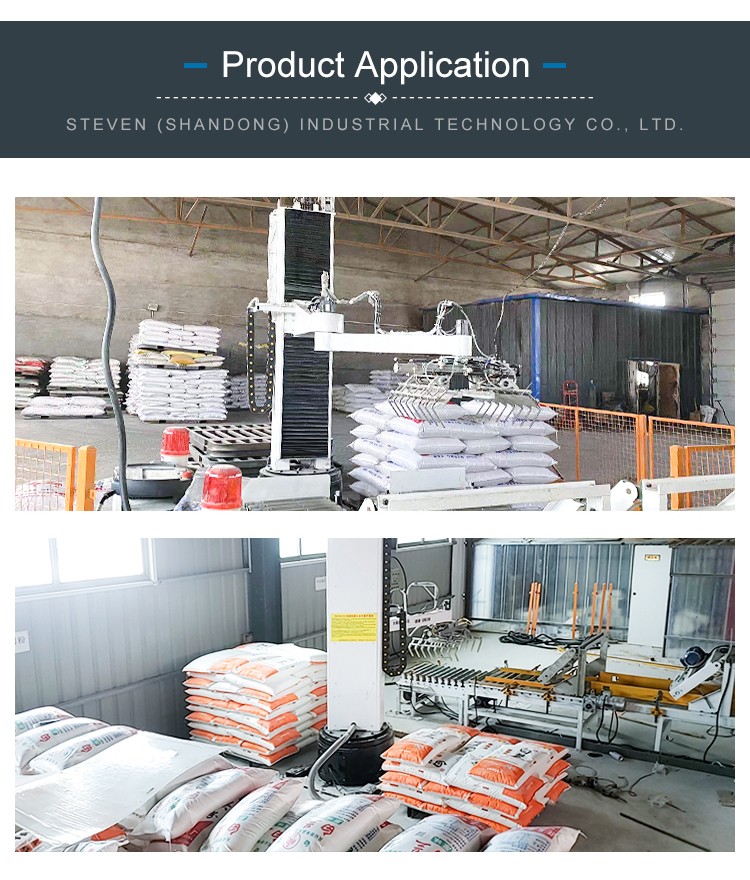

5. Designed for industrial environments, it can operate stably under harsh working conditions such as dust, humidity, and high temperature, and can adapt to the production environment of different industries.

6. Usually as part of a fully automated production line, it can be seamlessly connected with other equipment such as packaging machines, conveyor belts, and storage systems.

It is usually composed of vertical columns, arms, manipulators and cargo clamps. The vertical columns provide support and stability for the robot, the arms connect the columns and manipulators to enable the manipulators to move in different positions, and the manipulators and cargo clamps are used to grab and place objects.

The control system is responsible for directing the robot to perform various actions. Through preset programs or real-time instructions, it achieves precise control of each axis of the robot to ensure the accuracy and stability of the operation.

The power system generally uses servo motors as the power source to provide power for the robot's movement. It has the advantages of fast response speed, high control accuracy, and smooth operation, enabling the robot to accurately complete actions such as grasping and carrying.

There are usually 4 degrees of freedom, such as S-axis, Z-axis, R-axis, T-axis, etc. Each axis can achieve movement in different directions, allowing the robot to operate flexibly in space.

The maximum load is generally around 100kg. Robots with different load capacities can be selected according to actual needs to meet the requirements of carrying objects of different weights.

The maximum motion radius can reach about 1950mm, which determines the robot's working range and operable area. The repeat positioning accuracy can reach ±0.3mm, ensuring the accuracy and consistency of the robot's operation.