Industrial robot pallet Low-level palletizer and depalletizer

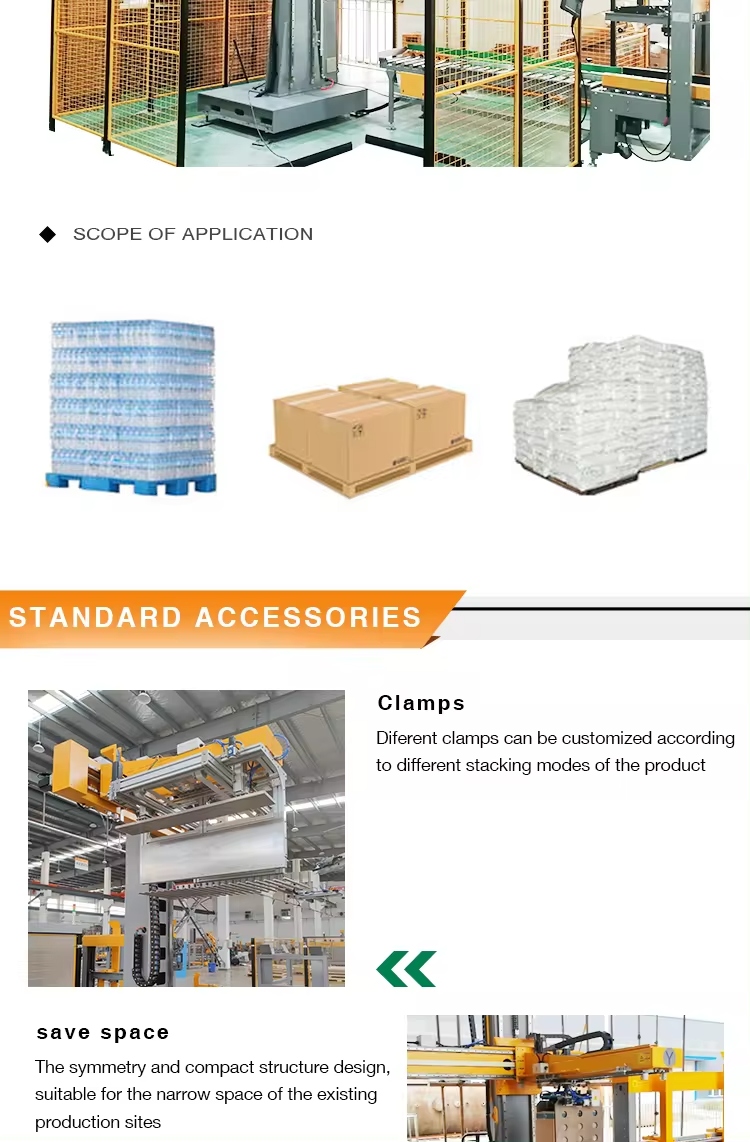

Industrial robot pallet Low-level palletizer and depalletizer is suitable for stacking bottles and cans. It is widely used in the stacking and destacking of mineral water beverage cans and other industries.

Configure the monitoring device for the storage capacity of the conveyor chain, and automatically adjust the production speed according to the monitoring data. The structure is simple and easy to maintain. The door of the control cabinet is installed with sealing rubber strips and equipped with high-quality ventilation and filtration devices. The equipment is equipped with multiple alarm lights, which can indicate different faults (faults that need to be reset, faults that automatically reset, operating instructions, etc.). The program design is reasonable, there is a fault prompt function. When the pile appears crooked, falling, scattered phenomenon can automatically stop. The safety protection net, operation platform, maintenance platform and its supporting columns are all treated with hot dipping zinc. The conveyor part of the protection plate (thickness is not less than 2mm), legs, guardrail cage (support rod diameter 16mm) and so on are made of stainless steel (SUS304), the chain plate is made of 1Cr13 chain plate produced by Huangshan chain factory, and the split sprocket processed by oily nylon is used. The safety protection device can automatically stop and alarm when the equipment is abnormal. The standard spraying machine frame is sandblasted with grade 2.5SAZ to comply with SIS regulations and degreased by solvent.

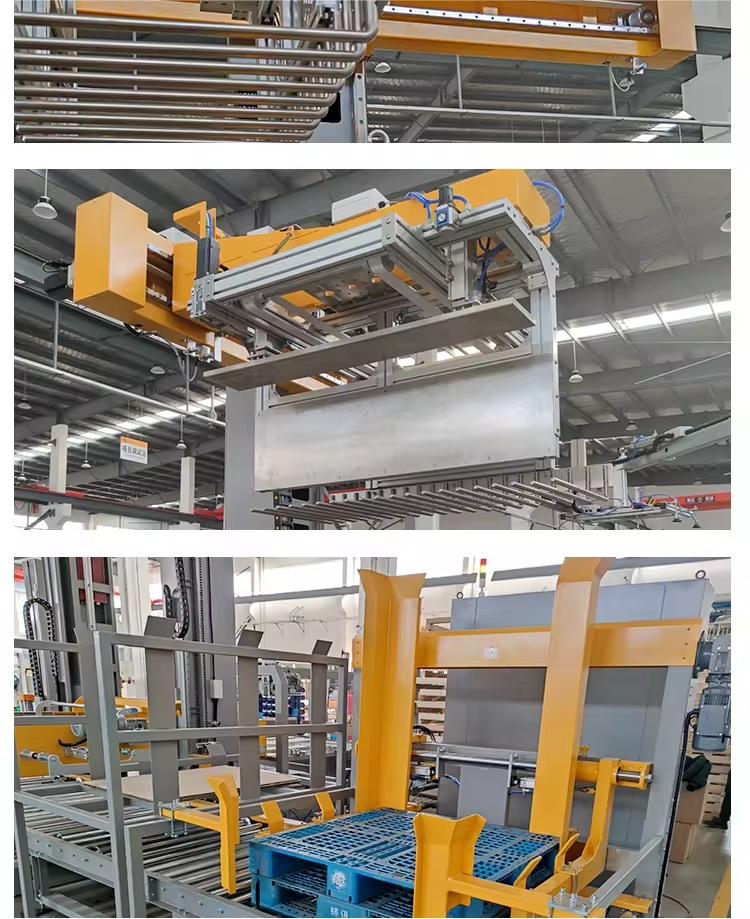

The finished product box is input from the single (double) track conveyor line, and directly transported to the conveyor drum of the marshalling station on the conveyor line, and pushed to the stacking area of the marshalling station under the action of the motor and the push plate controlled by the pneumatic control. The finished cases are entered from the single (double) channel conveyor line. When the boxes are transferred according to the needs of the palletizing format, they are moved from the conveyor belt to the drum conveyor line controlled by the photoelectric sensor and the pneumatic transfer device. The finished cases are transferred according to the required Angle. Through the automatic control of the count with photoelectric, proximity sensors; The upper push plate device of marshalling station pushes the finished cases stacked according to the palletizing format onto the transfer plate of the palletizing machine; The boxes are arranged in a neat layer and then enter the palletizing. Lift or lower to the operating height by the conveyor plate controlled by the motor and photoelectric, proximity sensor; The conveying plate moves to the top of the stacking plate, and the stopper and conveying plate cooperate with the movement of the whole layer of finished cases on the pallet. The conveyor plate returns to the docking station... Repeat the action code to the preset number of layers.