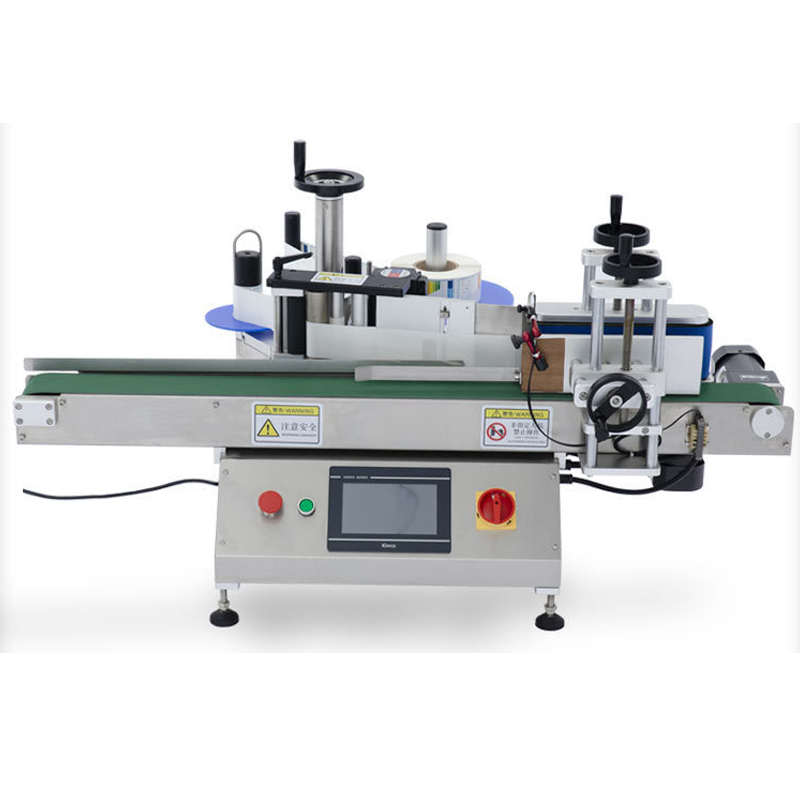

Double Side Sticker Labeling Machine

Double Side Sticker Labeling Machine

Purpose: To realize automatic attachment of self-adhesive labels and self-adhesive films on the flat side of the product, the large arc surface of the side, and the square peripheral surface;

Function: Improve the efficiency of product labeling and film sticking, with accurate positioning, good quality and high stability; avoid manual labeling and sticking

The film has low efficiency, a series of problems such as skewed attachment, blistering and wrinkles, irregular attachment positions, etc.; effectively reduces product costs and improves product quality.

Improve the aesthetics of the logo and enhance product competitiveness.

Scope of application: Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.;

Applicable products: Products that require labels to be attached to the side plane, large arc surface, circumferential surface, or square circumferential surface;

Application industries: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, printing and other industries;

Application examples: Labeling of flat bottles of shampoo, labeling of flat bottles of lubricants, labeling of round shampoo bottles.

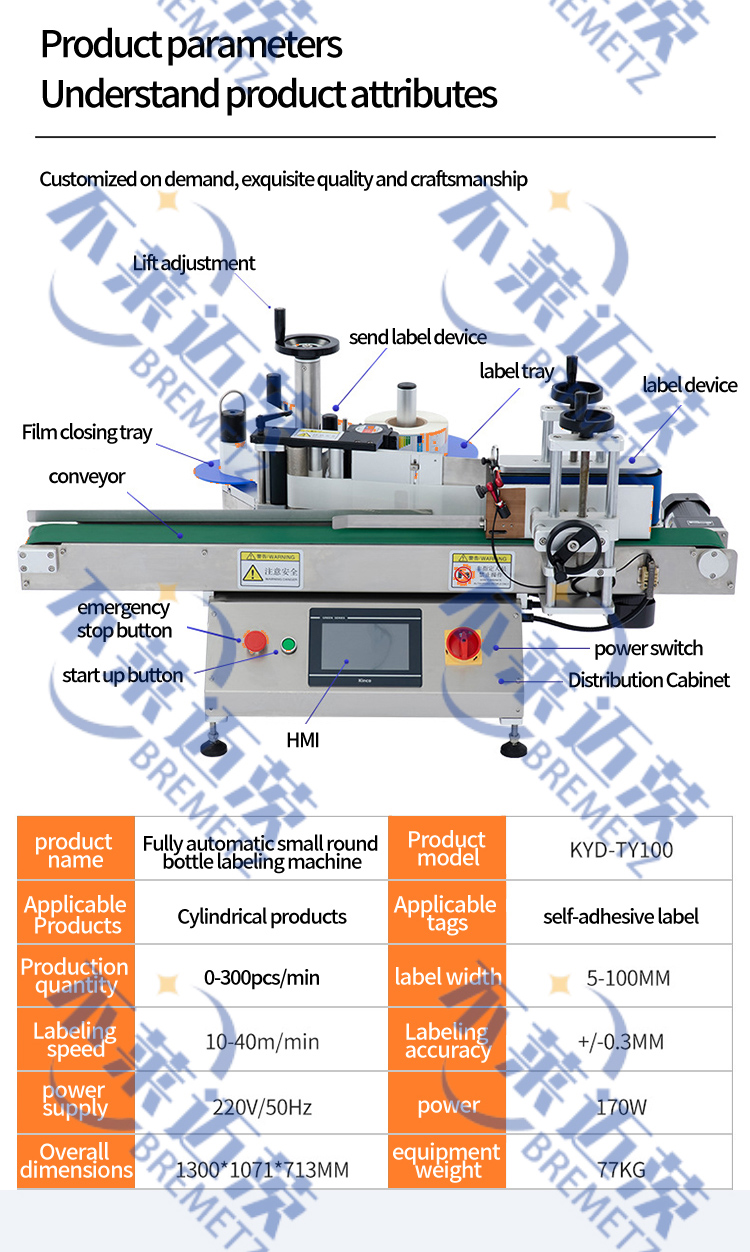

Core working principle: The sensor detects the passing of the product and transmits a signal back to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the position of the product to be labeled. The product flows through the labeling device, and the label is covered and attached. On the product, the attaching action of a label is completed;

The vertical labeling method is adopted, and a special positioning and top pressing device is installed to ensure the stability of the bottle; the machine head can be adjusted up and down, forward and backward, and tilted, suitable for labeling any irregularly shaped parts; a special label pressing device is installed to ensure The label is close-fitting and flat; it is tracked by a rotary encoder, and the speed of the conveyor belt can be adjusted at will while the label discharging speed is always synchronized with it.

Irregular-shaped parts are labeled; a special label pressing device is installed to ensure that the label fits snugly and flat; a rotary encoder is used to track the conveyor belt, and the speed of the conveyor belt can be adjusted at will, while the label discharging speed is always synchronized with it.

It adopts the most advanced human-machine interface operation, electric eye detection, PLC control, rotary encoder tracking, and frequency converter speed regulation to achieve true automation. It is suitable for double-sided labeling of symmetrical or asymmetric flat, square, oval, cylindrical, conical and special-shaped bottles in the food, cosmetics, daily necessities and pharmaceutical industries.