Ointment and liquid filling machines

1. High-precision metering system: Equipped with advanced volumetric, weight or flow metering devices, it can accurately and quantitatively fill ointments and liquids. For liquids, whether it is low-viscosity medicine or high-viscosity syrup, its metering accuracy can reach a very small error range.

2. Multiple filling modes are optional: You can choose the appropriate filling mode according to different product characteristics and packaging specifications. For small-dose eye drops and other liquid products, a micro-filling mode can be used to accurately control the volume of each drop.

3. High-speed filling capacity: With a fast filling speed, it can complete the filling task of a large number of products in a short time.

4. Continuous and stable operation: The well-designed mechanical structure and control system ensure the stability of the machine during long-term operation. The fit between the various components is tight and durable, and can withstand continuous filling operations.

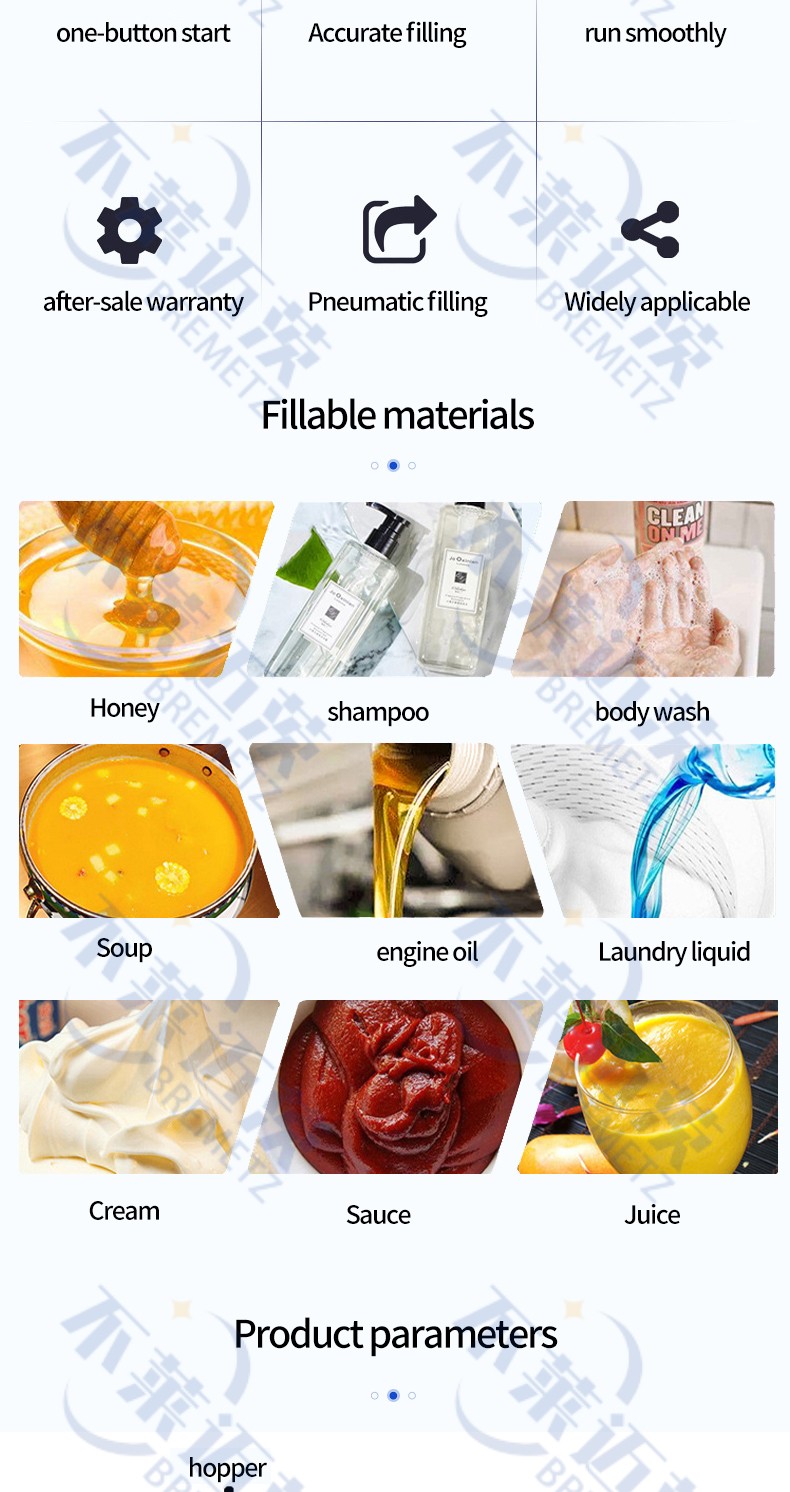

5. Compatible with a variety of materials: It has good adaptability to different types of ointments and liquids. It can fill liquids of various viscosities, whether it is soft skin cream or high-hardness medicinal ointment, it can be filled smoothly.

6. Adapt to a variety of packaging containers: It can match packaging containers of various shapes and sizes. Whether it is bottles, boxes, containers, or openings of different calibers, the filling machine can achieve accurate filling by adjusting parameters such as the position, shape and size of the filling head.

Ointment and liquid filling machine is an advanced mechanical equipment specially designed for precise filling of ointment and liquid products. It combines advanced technology and precision engineering design, and is widely used in many industries such as medicine, daily chemicals, and food. It can meet the filling needs of ointments and liquid products with different viscosities and different packaging forms, ensuring product quality and production efficiency.

With a wide range of material adaptability, it can handle liquids of various viscosities and ointments of different textures. From low-viscosity liquids such as alcohol and water to high-viscosity syrups, vaseline, etc., from soft skin creams to harder medicinal ointments, all can be filled smoothly on this filling machine. This wide range of material adaptability makes it widely used in multiple industries and meets the production needs of different products.

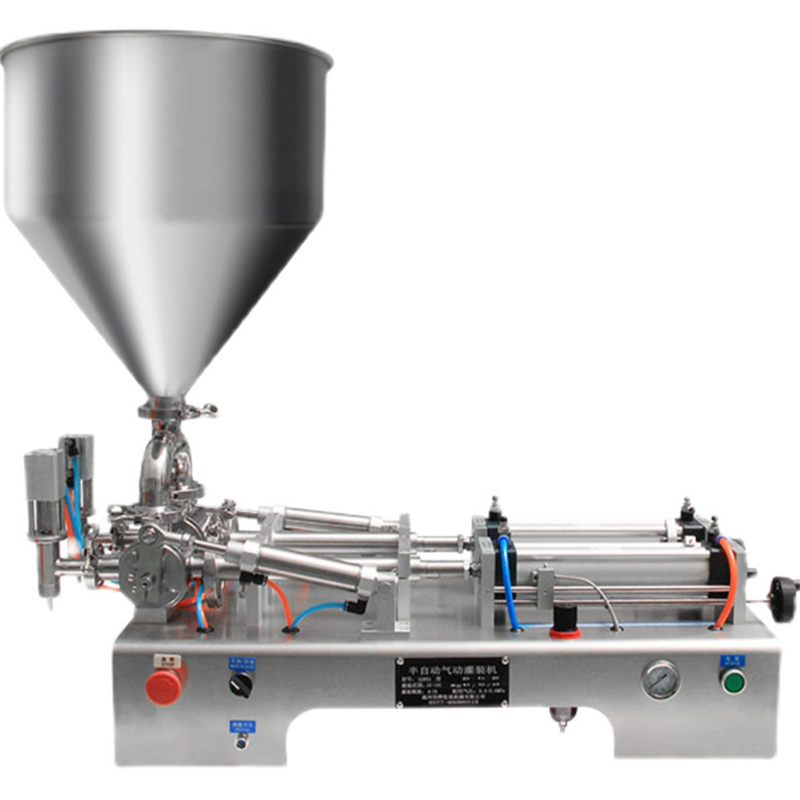

product name:filling machine

Machine power:50W

working pressure:0.5-0.7mpa

Voltage:220V/50HZ (110V can be customized)

Filling accuracy:≤±1%

Filling range:50-500ml

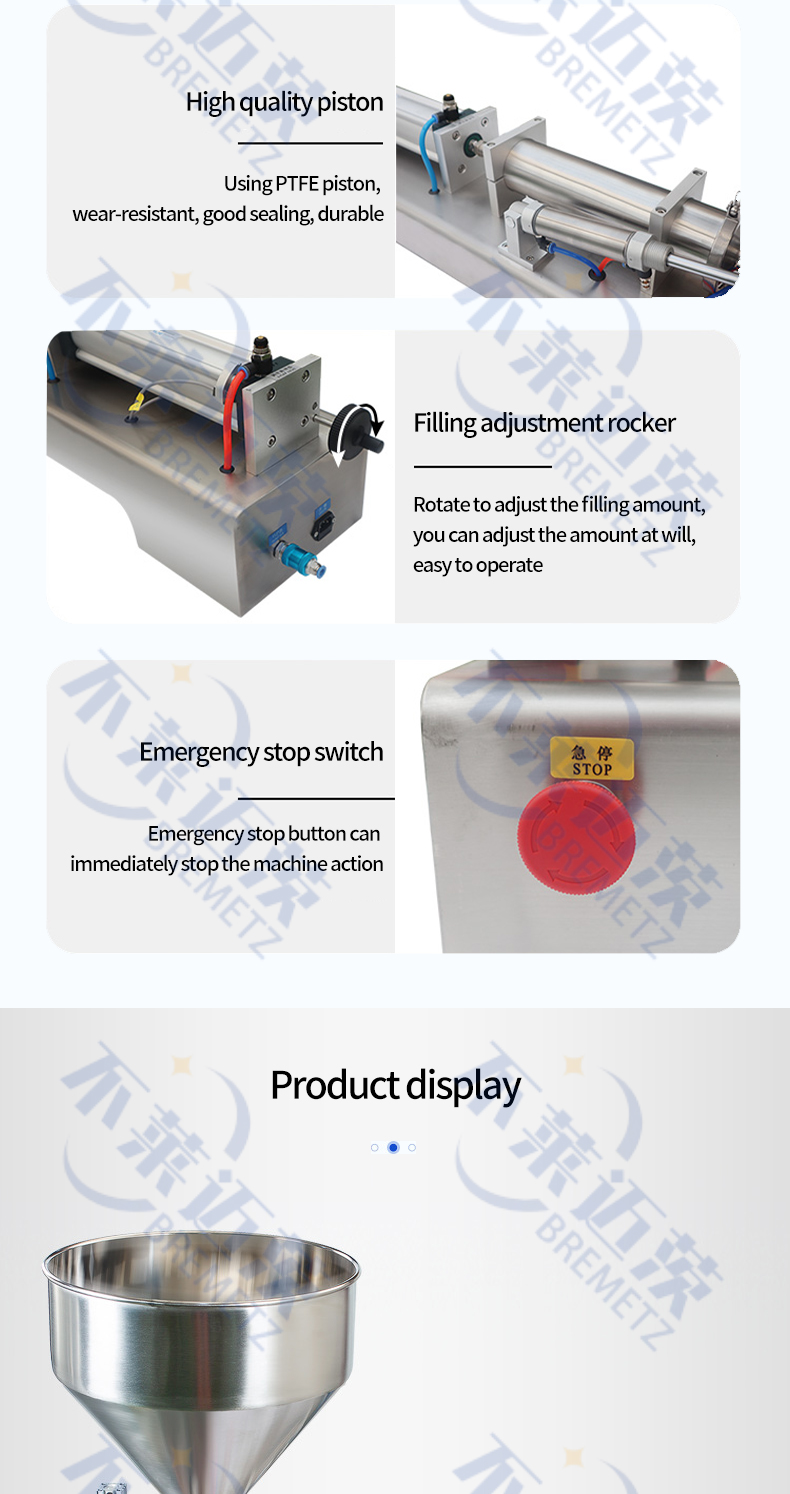

BRE High quality piston,Using PTFE piston, wear-resistant, good sealing, durable.

Filling adjustment rocker,Rotate to adjust the filling amount, you can adjust the amount at will, easy to operate.

Emergency stop switch,Emergency stop button can stop the machine action.

With advanced metering devices, extremely high filling accuracy can be achieved. Whether it is a small dose of liquid medicine or a large volume of ointment products, the filling amount can be accurate.

With a high filling speed, a large number of products can be filled in a short time. Depending on the model and configuration, the filling speed can reach dozens or even hundreds of filling operations per minute.

It supports multiple filling modes, such as quantitative filling, continuous filling, multi-stage filling, etc. Quantitative filling is suitable for fixed-dose products, such as medicines; continuous filling can be used for large containers or batch filling; multi-stage filling can be used for some special products, such as layered or mixed filling products, to achieve complex filling processes.

The company provides a professional installation team to install the filling machine to the location specified by the user and conduct comprehensive commissioning. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.