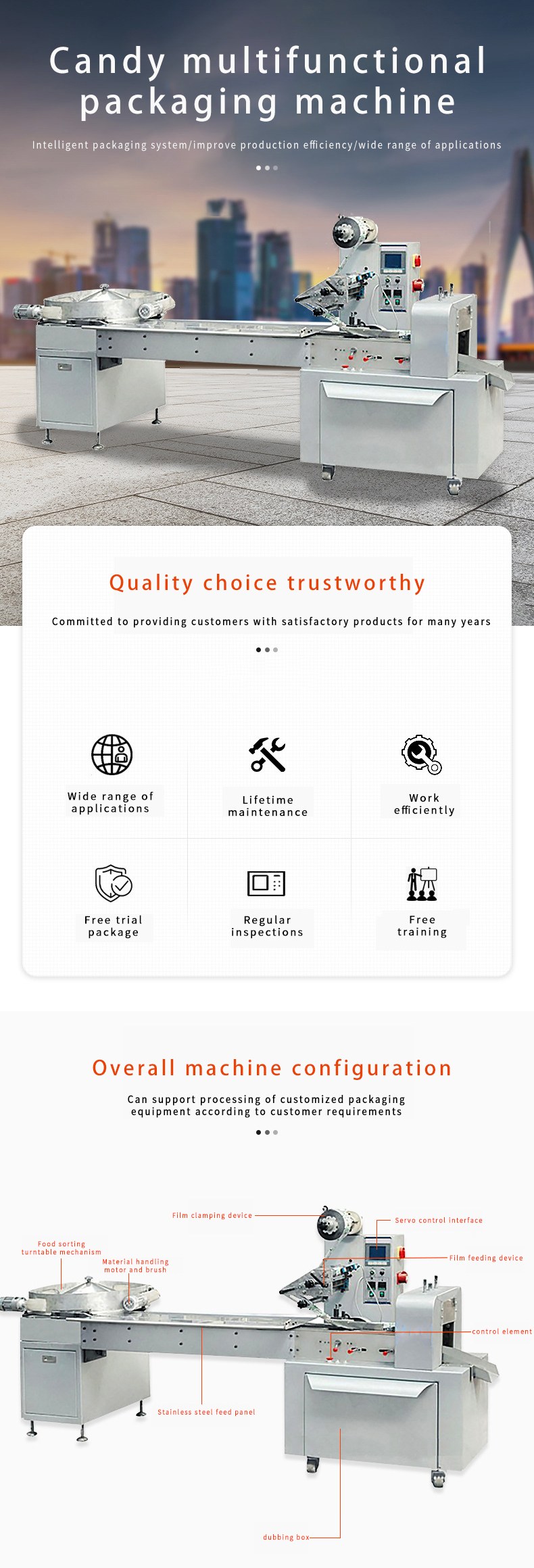

Multifunctional food packaging machine

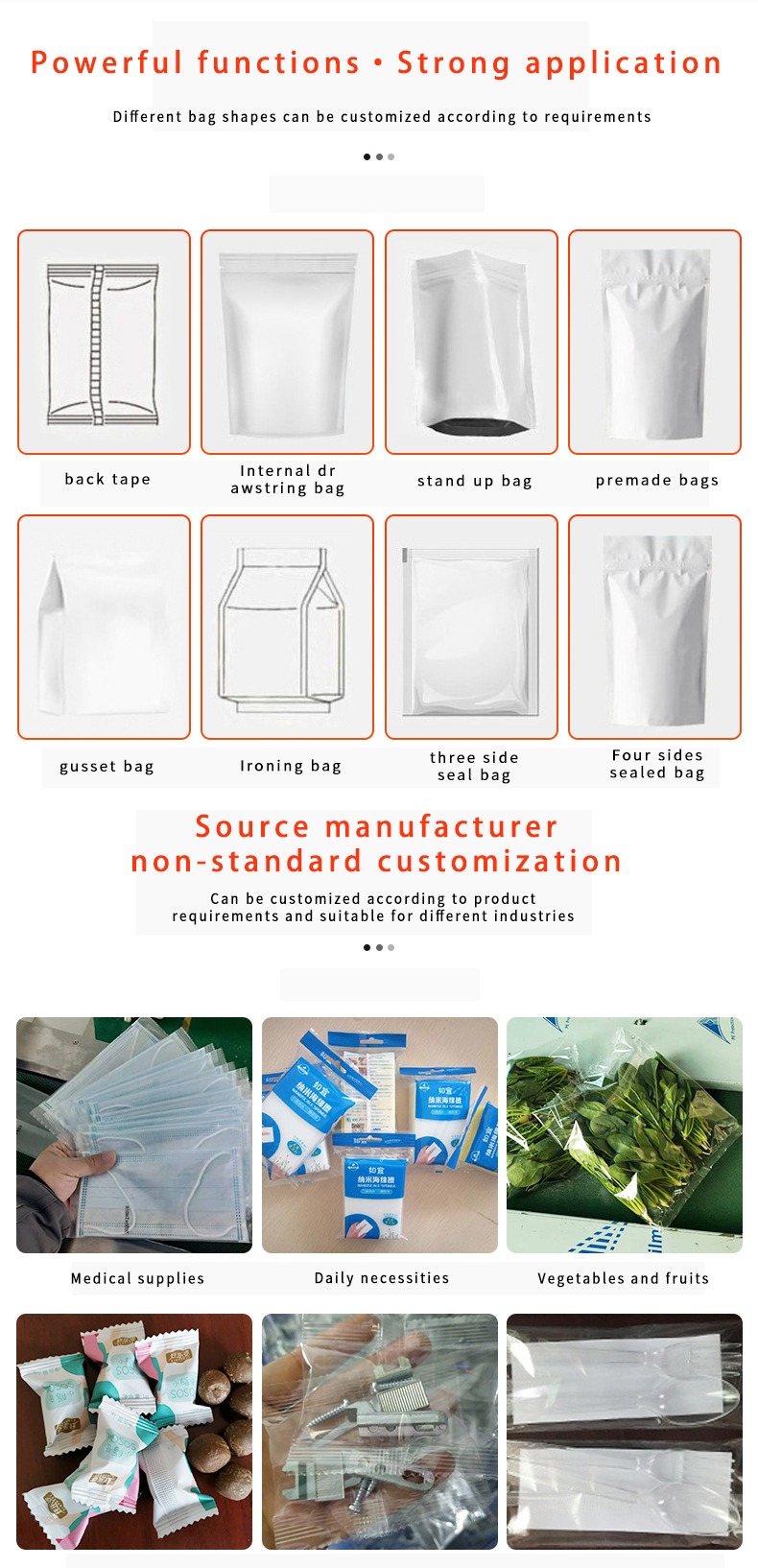

1. It can realize packaging of various bag types such as self-supporting bags, and can also be packaged in bottles, cans and other forms to meet the packaging needs of different foods.

2. Equipped with different metering devices, it can accurately measure foods of different forms and properties to ensure that the weight or volume of the food in the package is accurate.

3. It integrates multiple additional functions such as labeling, coding, coding, heat shrinking, vacuum packaging, etc., and can complete multiple packaging processes on one device.

4. Using advanced automation technology, the entire process from material conveying, metering, bag making, packaging to sealing is continuously automated without manual intervention.

5. Using convenient rapid mold change technology, operators can complete mold replacement and parameter adjustment in a short time, and easily switch to packaging of different bag types and sizes.

Multifunctional food packaging machine is the core tool of modern food processing industry. It integrates a number of cutting-edge packaging technologies and is committed to providing one-stop, comprehensive packaging solutions for various food companies.

A high-precision metering system is equipped for different forms of food. For granular food, a multi-head weigher is used to ensure the accurate weight of each bag; for powdered food, a spiral meter or vacuum powder suction meter is used to effectively prevent dust from flying.

It has a high-speed automated packaging process. From the material feed to the finished product output, there is no need for excessive human intervention throughout the entire process. All links are closely connected and work in collaboration.

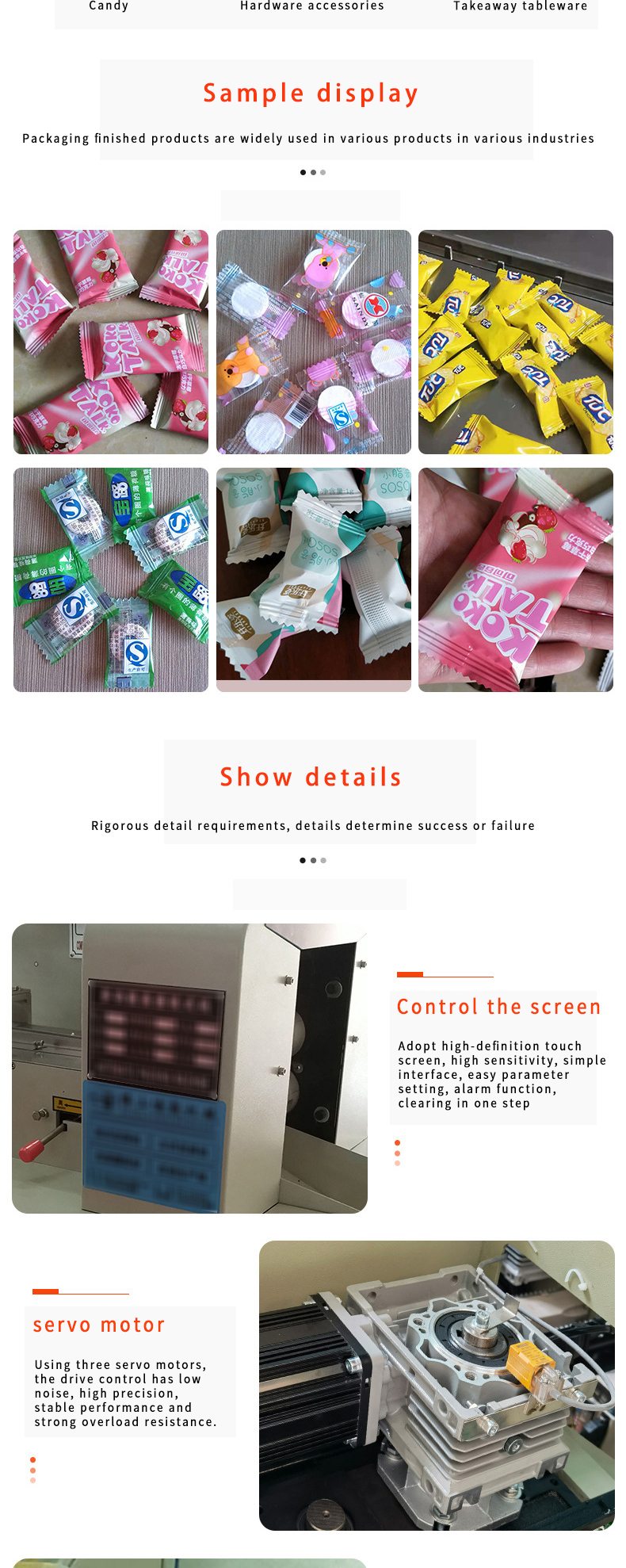

With high-precision sensors and sophisticated control systems, we can accurately control various parameters in the packaging process to ensure that each packaging unit is sealed tightly, flatly, and has a regular bag shape.

Equipped with a user-friendly touch screen operation interface, operators only need simple training to easily master the equipment's start, stop, parameter setting, fault diagnosis and other operations, reducing labor costs and training costs.

The overall structure of the equipment is well designed, easy to disassemble and clean, and key components are made of high-quality and durable materials with a long service life. In addition, the maintenance service network is perfect. Once a failure occurs, professional technicians can respond quickly and solve the problem in time to reduce downtime losses.