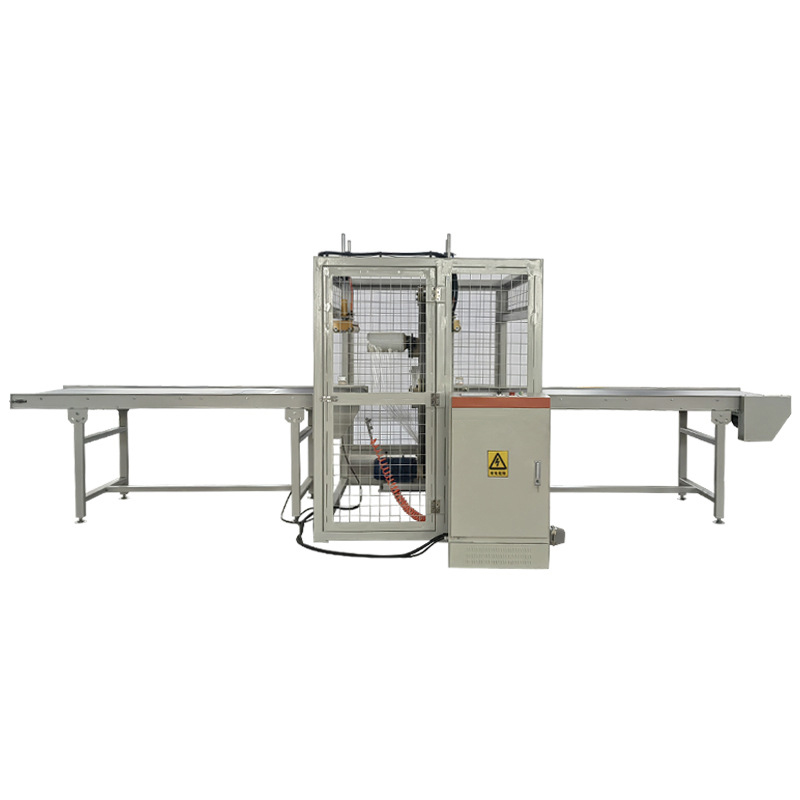

High speed horizontal winding machine

1. The equipment has a powerful power system and optimized transmission components, which can make the winding or winding action repeated in a short time.

2. The design fully considers the needs of long-term continuous operation, and selects high-quality wear-resistant materials and structures with good heat dissipation performance.

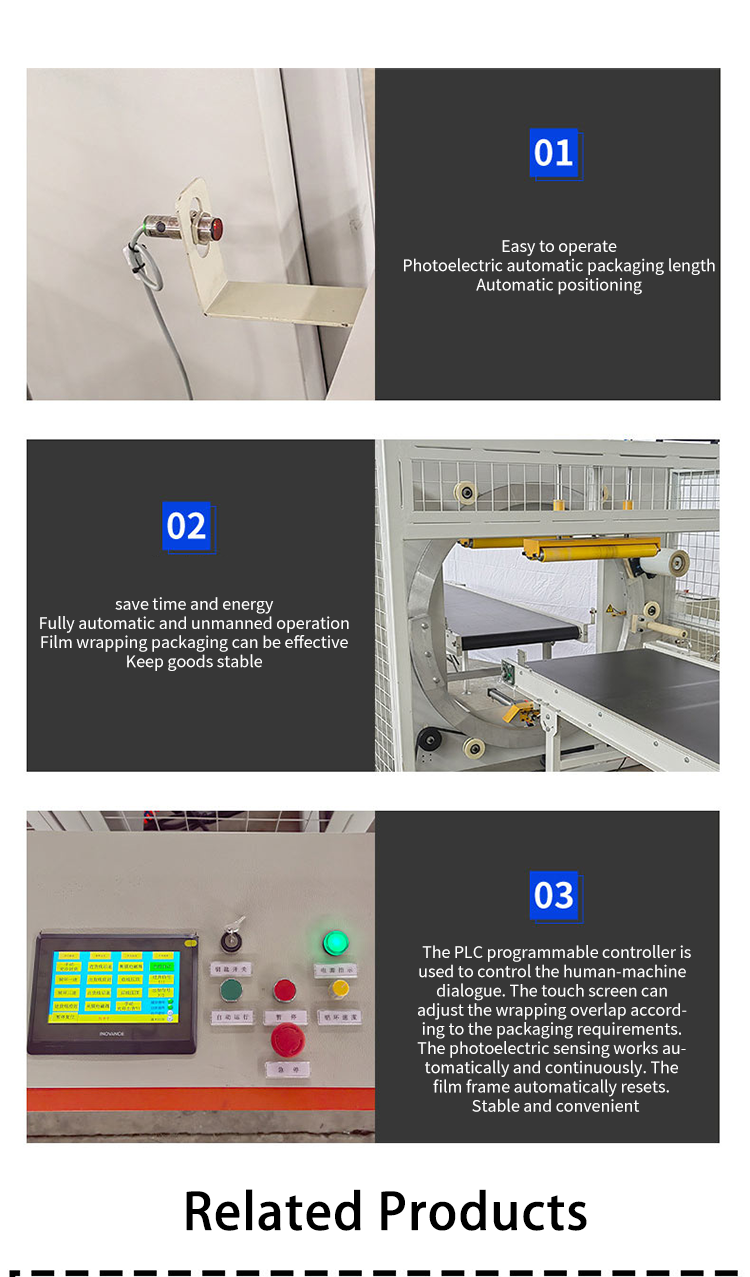

3. Built-in advanced PLC control system and high-precision sensors can monitor and accurately control various winding parameters in real time

4. Through precise mechanical structure and intelligent control algorithm, accurate starting positioning and uniform wiring can be achieved.

5. With flexible parameter adjustment function, winding objects of different diameters and lengths can be processed through simple operation settings or replacement of a small number of accessories.

The horizontally placed structure makes the winding process more stable, which is especially suitable for processing longer or larger winding objects, such as large cable reels, long pipes, etc. It can effectively prevent shaking or deformation caused by the object's own weight or winding tension during the winding process.

The various functional components of the equipment usually adopt modular design, such as the wire release unit, winding host, electronic control system, etc., which is convenient for maintenance and upgrading. When a component fails, the corresponding module can be quickly replaced to reduce downtime; at the same time, it is also convenient to customize the equipment according to different production needs.

Equipped with advanced tension control system, it can accurately control the tension during winding, and the tension control accuracy can reach ±1% or higher. It can effectively avoid the stretching or deformation of the material.

It has a high-precision cable arrangement function with an accuracy of ±0.1mm or higher, ensuring that the winding material is evenly and neatly arranged on the object being wound, avoiding problems such as overlapping wires and jumper wires, and improving the appearance quality and performance of the product.

It can realize a series of automatic operations such as automatic feeding, automatic winding, automatic cutting, automatic unloading, etc., which reduces manual intervention, reduces labor intensity, and improves production efficiency and product quality stability.

It adopts advanced PLC control system or CNC system and has a human-computer interaction interface, which can display the equipment's operating status, parameter settings, fault alarm and other information in real time.Operators can easily adjust parameters and perform operation controls through the touch screen or operation panel. The system also has data storage and statistical functions to facilitate production management and quality traceability.