What is the manipulator in a palletizing robot

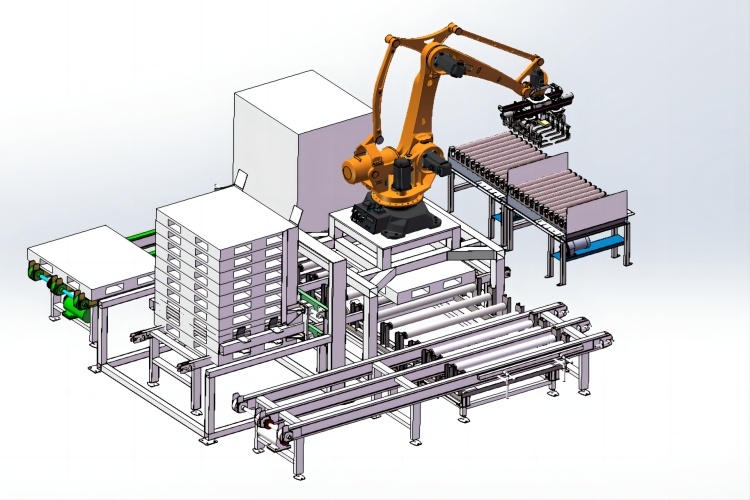

On many production lines, palletizing robots are often used to transport and stack goods. The application of palletizing robots can improve the labor efficiency several times than the traditional one, and can also reduce the labor cost of the company. What is the manipulator of a palletizing robot?

The palletizing robot's manipulator can mimic some of the postural functions of the human hand and arm for grasping and transporting items in a fixed program flow, or for fully automatic operation of the equipment for the actual operation of the tool. It is an early industrial robot, which can replace the complex work of people to carry out the specialization and automation of manufacturing, and is widely used in the transportation and stacking of automobiles, decorative building materials, food, packaging, chemical plants, grain, oil and food, hardware accessories, mechanical equipment and other industries.

The manipulator of the palletizing robot is mainly composed of three parts: the actuator, the driving mechanism and the automatic control system. The arm is a part used to grasp the product workpiece (or tool), according to the style, specifications, net weight, material and operation regulations of the captured item, there are a variety of structural forms such as clamping, clamping, adsorption, etc. The movement organization that causes the arm to rotate (shake), move, or combine to perform a specified posture, changing the specific position and posture of the object being grasped.

The above is an overview of the palletizing robot's manipulator. It has brought many benefits to the development of the manufacturing industry, not only makes the palletizing neat and beautiful, but also greatly improves productivity and saves a lot of labor costs for the company.