The working principle of laser automatic welding equipment

The working principle of automatic laser welding equipment needs to be introduced from various aspects such as laser generation, beam transmission, focus control, welding process and automatic integration. Laser automatic welding equipment has the advantages of high precision, high efficiency, low deformation rate and easy automatic control. The working principle of laser automatic welding equipment is introduced below.

What is the working principle of laser automatic welding equipment?

1. Laser generation

In automatic laser welding equipment, solid-state laser or fiber laser is usually used as the light source. The core components of the laser include laser crystal, pump source and resonator. A pump source emits light of a specific wavelength that excites Nd³ + ions in the laser crystal, causing it to transition from a low to a high energy state. Subsequently, Nd³ + ions in a high energy state release photons of the same wavelength, phase and direction of propagation as the pump light in a process of stimulated radiation in the resonator, which are continually reflected and amplified in the resonator to form a laser beam of high intensity, high monochromaticity and high coherence.

2. Beam transmission and focusing

After the laser beam is emitted from the laser, it needs to be transmitted and focused through a series of optical elements to ensure that it can accurately and stably act on the welding workpiece. These optical components include reflectors, beam expanding mirrors, focusing mirrors, etc. The mirror is used to change the propagation direction of the laser beam to adapt to different processing layouts; The beam expanding mirror adjusts the divergence Angle by changing the diameter of the beam to ensure the quality of the beam during long distance transmission. The focusing mirror is to converge the laser beam to a very small focus, forming a high energy density spot, which is the key to achieve laser welding.

3. Focus control and welding process

The focus position of laser welding is very important for welding quality. Through the fine focus control system, the focus position of the laser beam can be adjusted in real time to meet the welding needs of different thicknesses and different materials. In the welding process, the high energy density spot of the laser beam instantly heats the surface of the workpiece, so that the metal quickly melts or even vaporizes, forming a melt pool. At the same time, the deep penetration ability of the laser beam and the high heating speed make the metal on both sides of the weld quickly melt and mix, forming a strong metallurgical bond. In addition, the heat generated during laser welding is highly concentrated and the heat affected zone is small, which is conducive to reducing welding deformation and cracks and other defects.

4. Automatic integration and intelligent control

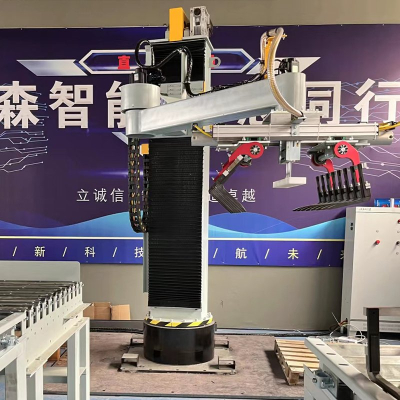

The laser welding system integrates sensor technology, machine vision technology, robot technology and intelligent control algorithm to realize the whole process of welding monitoring and accurate control. Through the machine vision system, the image information of the welding area can be captured in real time, and the parameters such as the position, width and depth of the weld can be accurately measured and adjusted. The intelligent control algorithm can automatically adjust the laser power, welding speed and other process parameters according to the changes of welding parameters to ensure the stability and consistency of welding quality. In addition, the application of robot technology further improves the flexibility and efficiency of welding operations, making laser welding capable of welding complex shape workpieces.

The above is the introduction of the working principle of laser automatic welding equipment, automatic welding equipment has been widely used in various industries, its high precision, strong stability, high efficiency characteristics for the transformation and upgrading of the manufacturing industry and development to provide strong support.