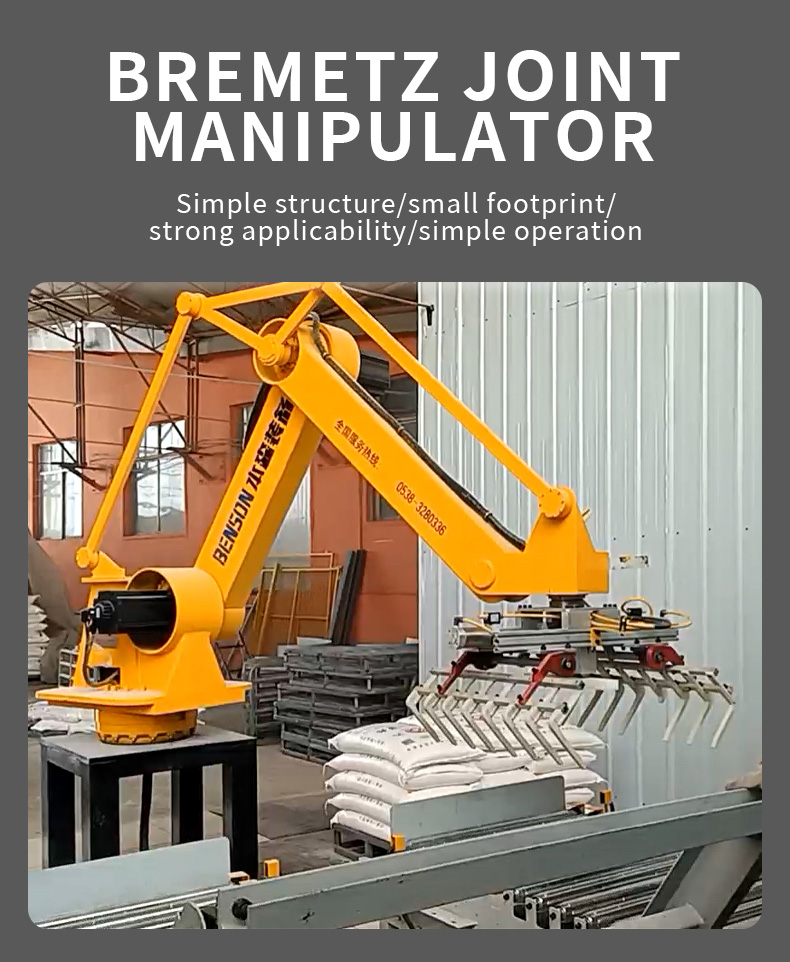

Fully automatic joint robot

1. Its joint design makes the overall structure of the robot relatively compact, and it can achieve multi-degree-of-freedom movement in a limited space.

2. It is generally equipped with 5-6 axes, which can imitate the movement of human arms, and can achieve operations of almost any trajectory and angle. It can accurately reach complex work paths and target positions.

3. It can perform precise operations according to preset programs and parameters, with high repeatability and consistency, and can effectively avoid mistakes and errors caused by human factors.

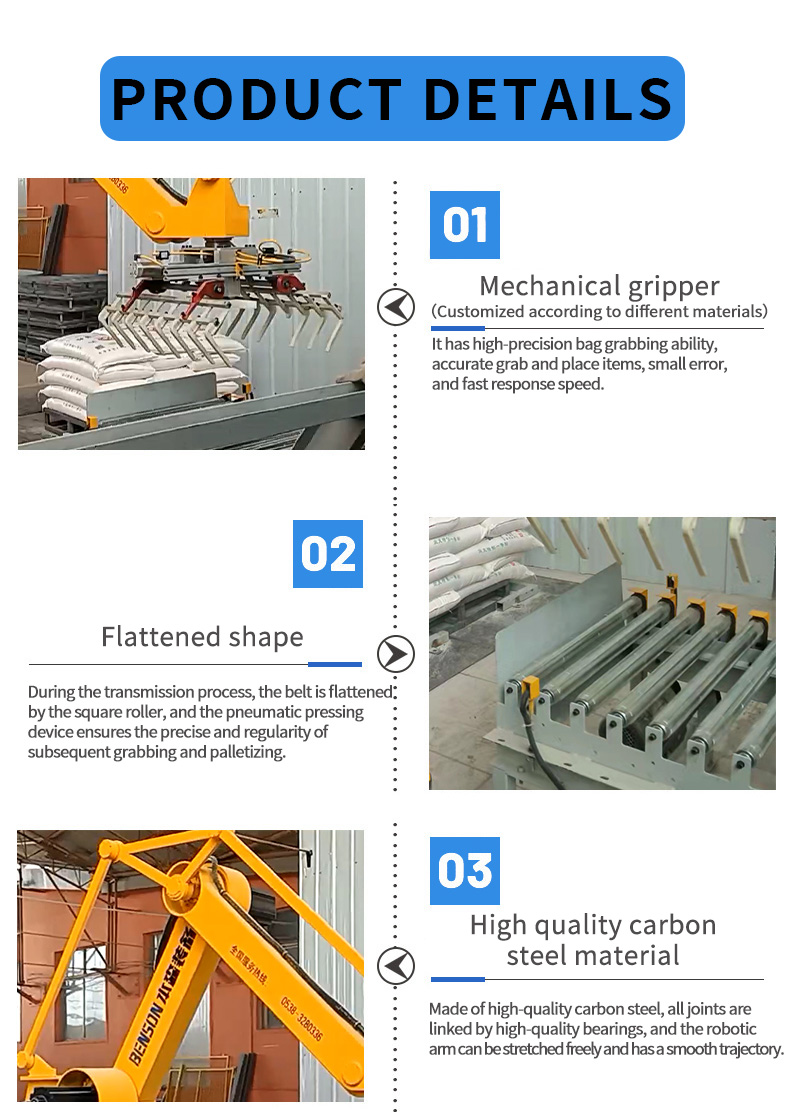

4. By replacing different end effectors, it can quickly adapt to various work tasks and production needs, realizing the multifunctional application of robots.

5. It is equipped with intelligent integrated joints, integrated sensors, actuators and control algorithms, so that the robot can perceive environmental changes in real time and make corresponding adjustments and decisions.

The fully automatic joint robot is known for its highly precise and flexible structural design. It uses the principle of bionics to simulate the joint structure of the human arm. It is usually composed of multiple joints connected in sequence to form the main body of the robot.

The joints of the robot arm are made of high-strength, lightweight alloy materials, which ensures that the structure is stable enough to withstand various workloads and movement impacts, while minimizing its own weight, which is conducive to achieving high-speed, high-precision motion control.

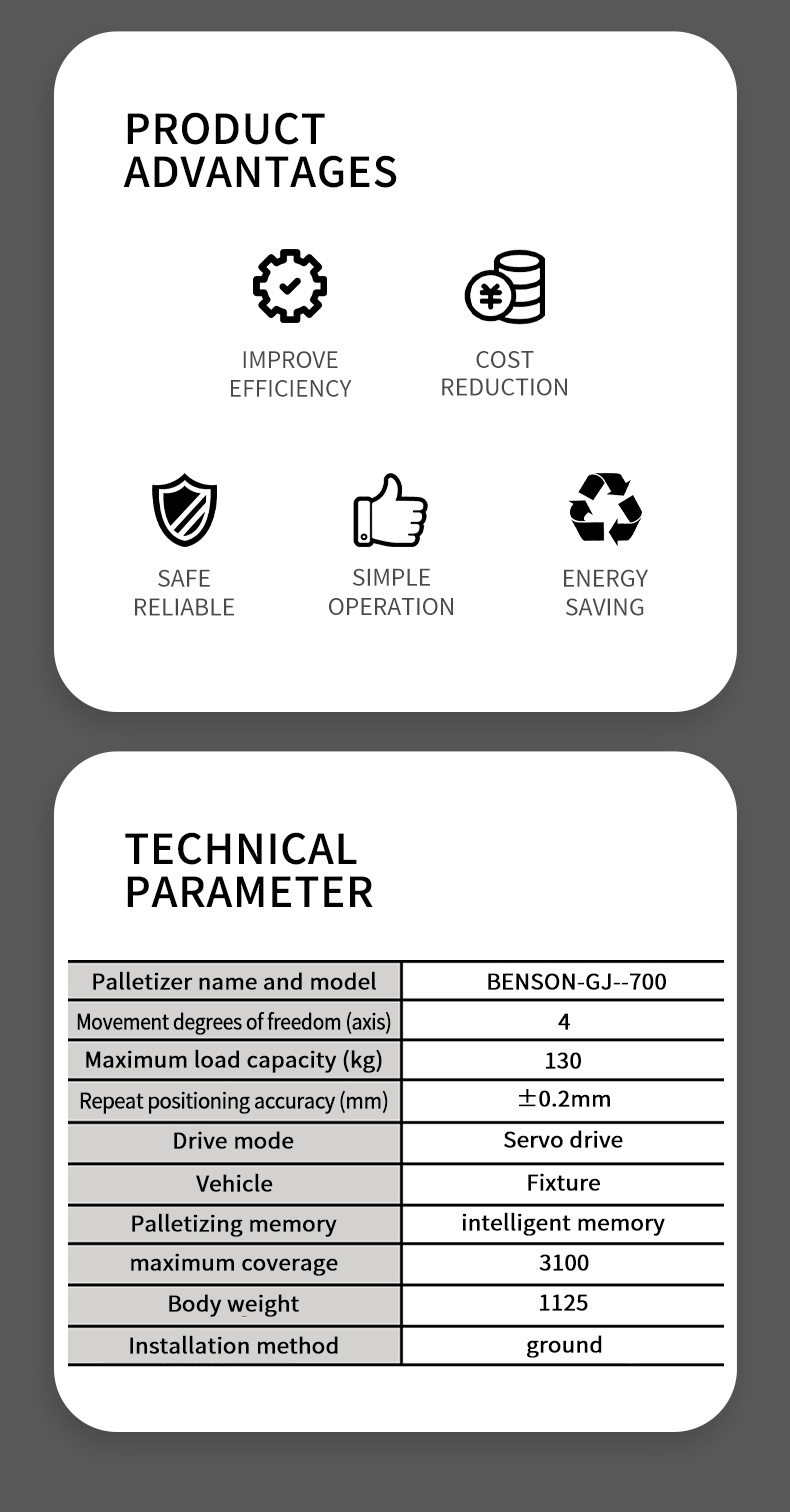

Palletizer name and model:BENSON-GJ--700

Movement degrees of freedom (axis):4

Maximum load capacity (kg):130

Repeat positioning accuracy (mm):±0.2mm

Drive mode:Servo drive

Vehicle:Fixture

Palletizing memory:intelligent memory

maximum coverage:3100

Body weight:1125

Installation method:ground

With industrial-grade dedicated controller as the core, it runs powerful and intelligent robot control software. The control system adopts multi-axis linkage control technology, which can coordinately control multiple joints of the robot at the same time.

For different application tasks, the robot can be equipped with various types of end effectors, and these end effectors have the function of quick replacement, which further enhances the versatility and adaptability of the robot.

Industrial manufacturing: In the automotive manufacturing industry, fully automatic articulated robots are widely used in key production links such as body welding, parts assembly, and painting.

In the mechanical processing industry, fully automatic articulated robots can undertake tasks such as loading and unloading, parts processing, grinding and polishing.

Logistics and warehousing: In modern logistics warehouses, fully automatic articulated robots are used to realize automatic handling, sorting and storage of goods.

We provide a full range of repair and maintenance services, including regular maintenance and fault repair. For regular maintenance, we will develop a personalized regular maintenance plan for customers based on the robot's usage and running time.