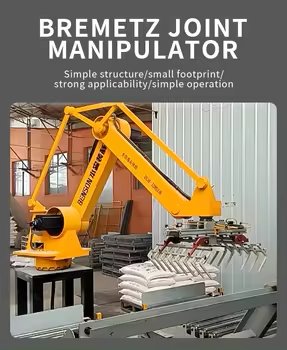

High-efficiency and precise joint robot

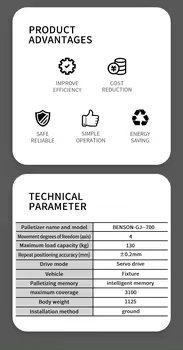

1. Equipped with high-performance servo motors and advanced transmission systems, each joint can respond to instructions quickly and achieve high-speed movement and operation.

2. Adopting high-precision reducers, encoders and advanced motion control algorithms, the repeatability and absolute positioning accuracy are very high.

3. The multi-joint design gives it multiple degrees of freedom and can perform complex movements and path planning in three-dimensional space.

4. Equipped with a user-friendly programming interface and offline programming software, operators can quickly master programming methods through simple training.

5. According to different application requirements, end effectors of different load levels can be configured to withstand larger loads.

Usually composed of multiple joints, each joint has a specific degree of freedom, which can achieve flexible movement. For example, the common four-axis or six-axis robots, each joint works together to enable the robot to complete complex movements in three-dimensional space.

The arm connects the joints and the end effector, has a certain length and load capacity, and can be designed according to different work requirements. There are various types of end effectors, such as grippers, suction cups, welding guns, etc., which are used to complete specific tasks such as grasping, handling, welding, etc.

The fuselage is the main frame of the robot, providing support and installation foundation for various components, and must have sufficient strength and stability. The base is used to fix the robot to ensure that it does not shake or move during operation.

Real-time data interaction with multiple sensors, such as position sensors, force sensors, vision sensors, etc. Through the information fed back by the sensors, the controller can adjust the robot's motion state in real time to ensure that it completes the task accurately and improves the safety and reliability of the work.

The movement speed of joints generally ranges from tens to hundreds of revolutions per second. The overall movement speed of the robot depends on the coordinated movement of each joint and the complexity of the work task.