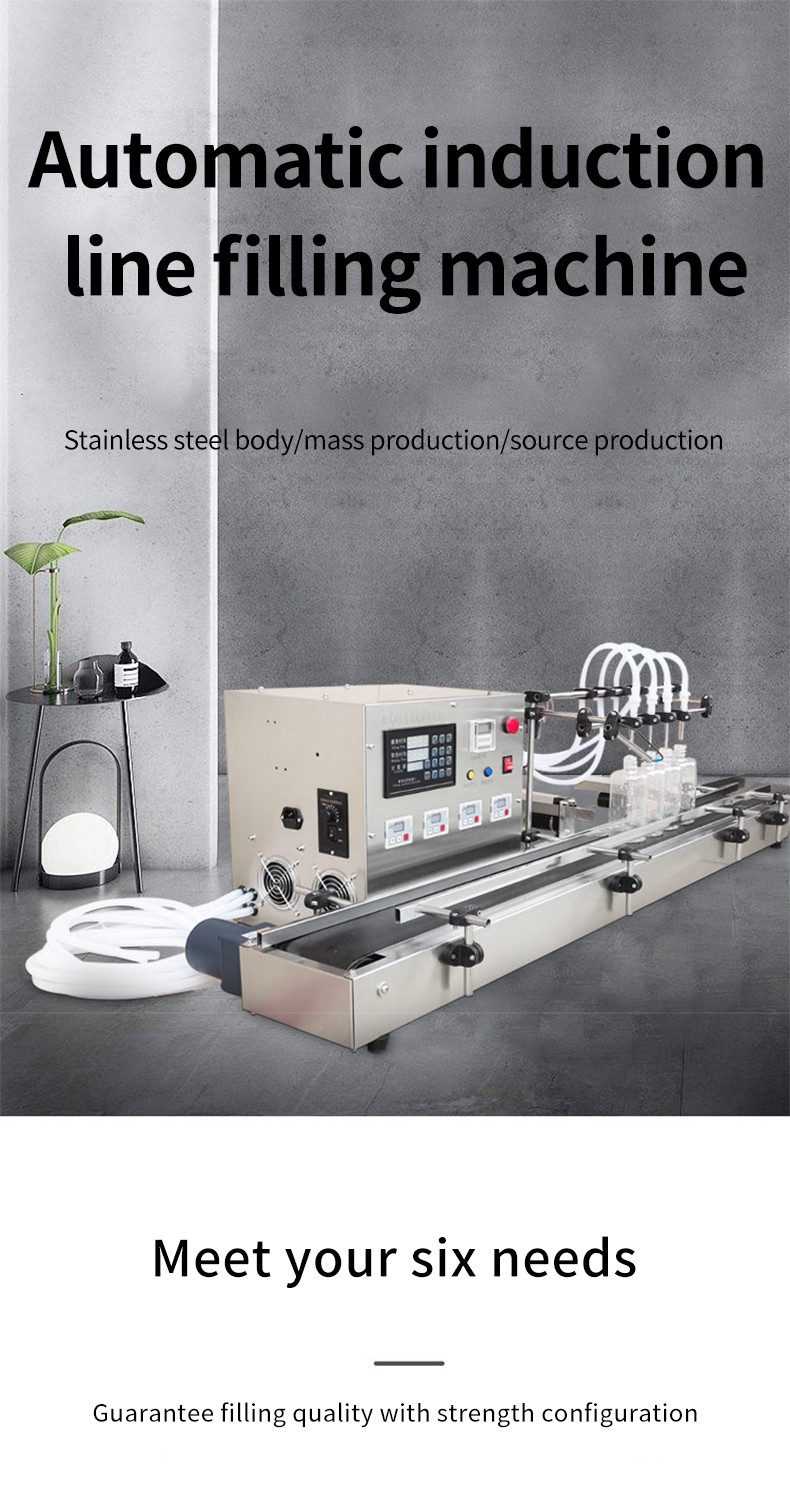

Automatic induction high speed assembly line filling machine

1. With excellent filling speed, it can complete the filling task of a large number of products in a short time, greatly improving production efficiency, and is suitable for large-scale, continuous production operations.

2. The use of advanced automation technology and precise mechanical structure can ensure that the machine remains stable during long-term operation, which helps to improve the overall production efficiency.

3. It can accurately control the filling volume to ensure that the filling volume of each product is within a very small error range, improving the consistency and stability of product quality.

4. Through advanced sensing technology, it can automatically identify the position and state of the container, achieve precise filling positioning, and ensure the accuracy and reliability of the filling process.

5. It has strong versatility and flexibility, and can adapt to the filling needs of containers and materials of different types, specifications and shapes. Only simple adjustments or replacement of some accessories are required to achieve filling production of a variety of products.

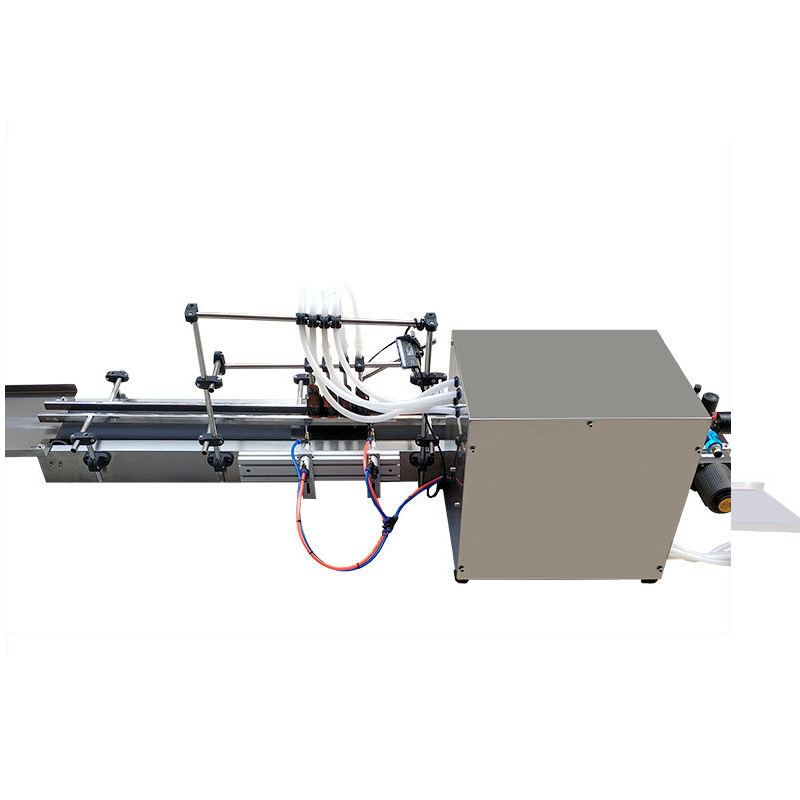

This automatic induction high-speed assembly line filling machine is mainly composed of material supply system, filling system, container conveying system, control system, frame and auxiliary devices. The overall design aims to achieve high-speed, accurate and automated filling operations to meet the strict requirements of modern large-scale production enterprises for production efficiency and product quality.

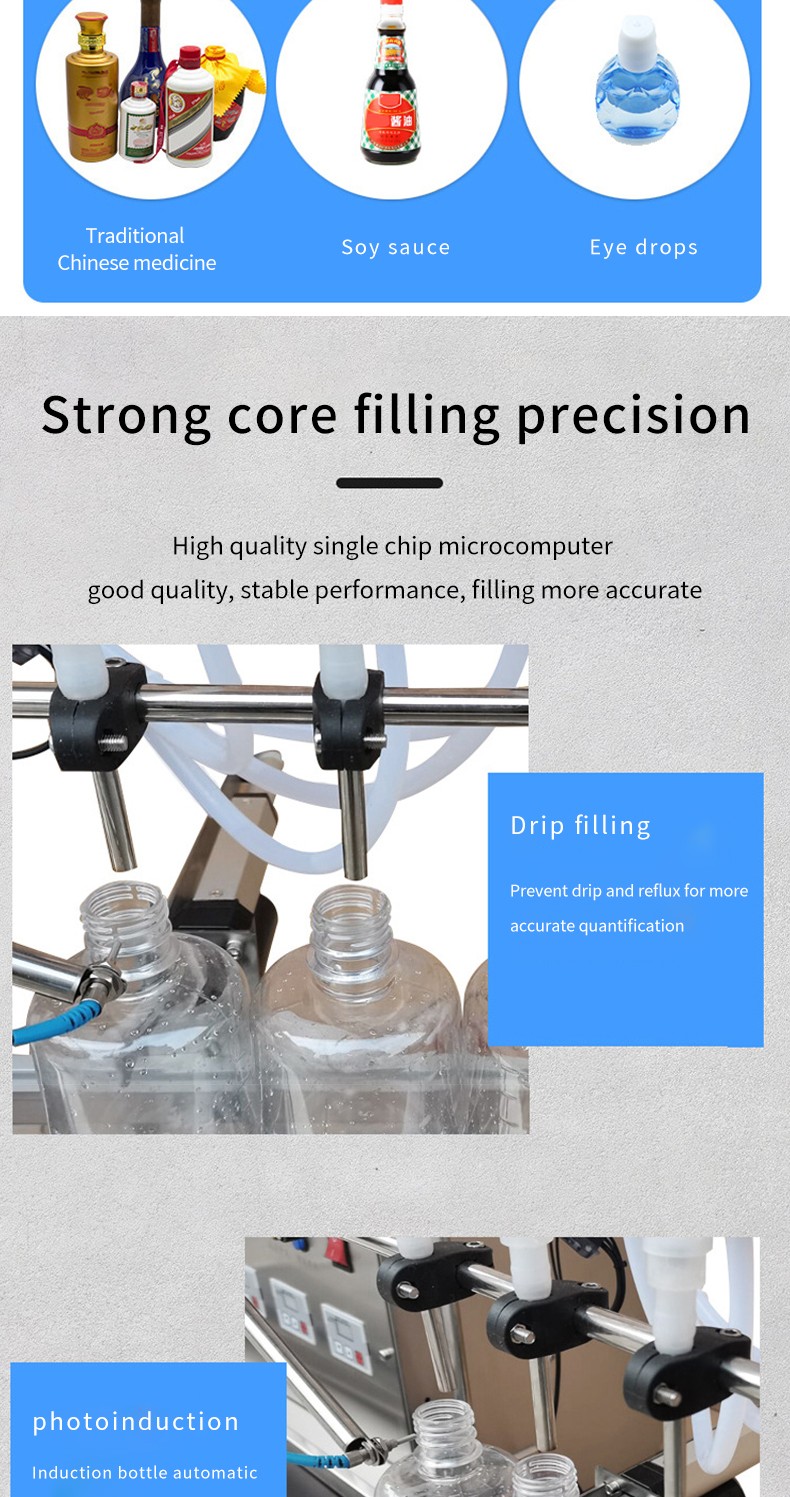

Imported high-precision flow meters, such as Coriolis mass flow meters or electromagnetic flow meters, are used to accurately measure the flow of materials, with a measurement accuracy of ±0.2% or even higher.

The filling head is made of stainless steel, and the internal structure is optimized to ensure the smoothness and stability of the material during the filling process.

The valve adopts solenoid valve or pneumatic valve, which has the characteristics of fast response speed and precise action. Solenoid valve is suitable for small flow and high frequency filling operation. Its switching time can be in millisecond level, which can realize fast filling start and stop control.

The container conveying system is equipped with high-precision positioning sensors, such as photoelectric sensors or fiber optic sensors, which can accurately detect the position and status of the container on the conveyor belt.

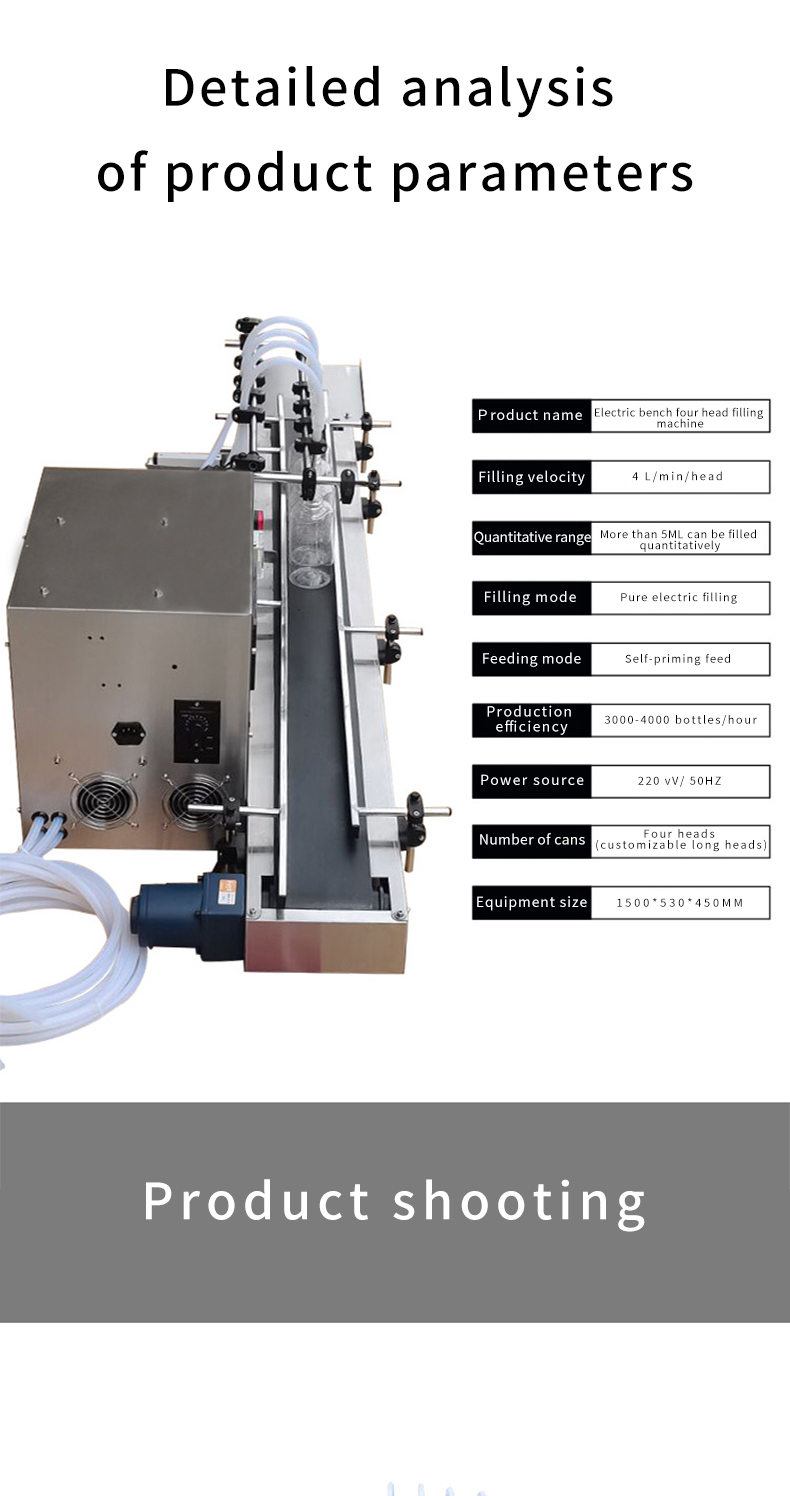

Product name:Electric bench four head filling. machine

Filling velocity:4 L/min/head

Quantitative range:More than 5ML can be filled quantitatively

Filling mode:Pure electric filling

Feeding mode:Self-priming feed

Production efficiency:3000-4000 bottles/hour

Power source:220 vV/50HZ

Number of cans:Four heads (customizable long heads)

Equipment size:1500*530*450MM

The conveyor belt is made of high-strength, low-friction coefficient materials, such as polyurethane or rubber, which has good wear resistance and anti-static properties, and can ensure the smooth operation of the container during the transportation process and reduce the shaking and deviation of the container.

Application scenarios:

Food and beverage industry: It can meet the needs of high-speed production lines and can fill thousands or even tens of thousands of bottles of beverages per hour, ensuring that the capacity of each bottle of beverage is accurate and meets national and corporate standards.

Pharmaceutical industry: Whether it is liquid medicine, syrup, injection, or powdered or granular medicine, high-precision filling equipment is required to ensure the accurate dosage of each medicine.

Daily chemical industry: The filling machine can achieve accurate and stable filling operations according to different packaging containers and product specifications, while avoiding leakage and splashing of materials, ensuring the appearance quality and user experience of the product.

Chemical industry: The filling machine can select appropriate materials and structural designs according to the characteristics of different materials to ensure the corrosion resistance and safety of the equipment.