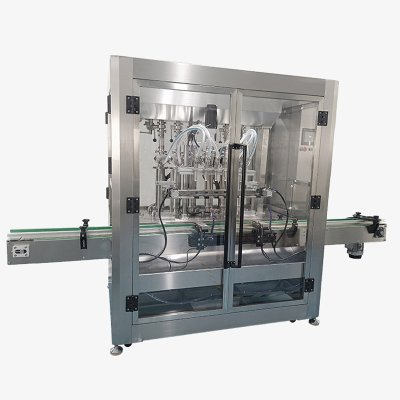

Liquid Filling Machine

Liquid Filling Machine

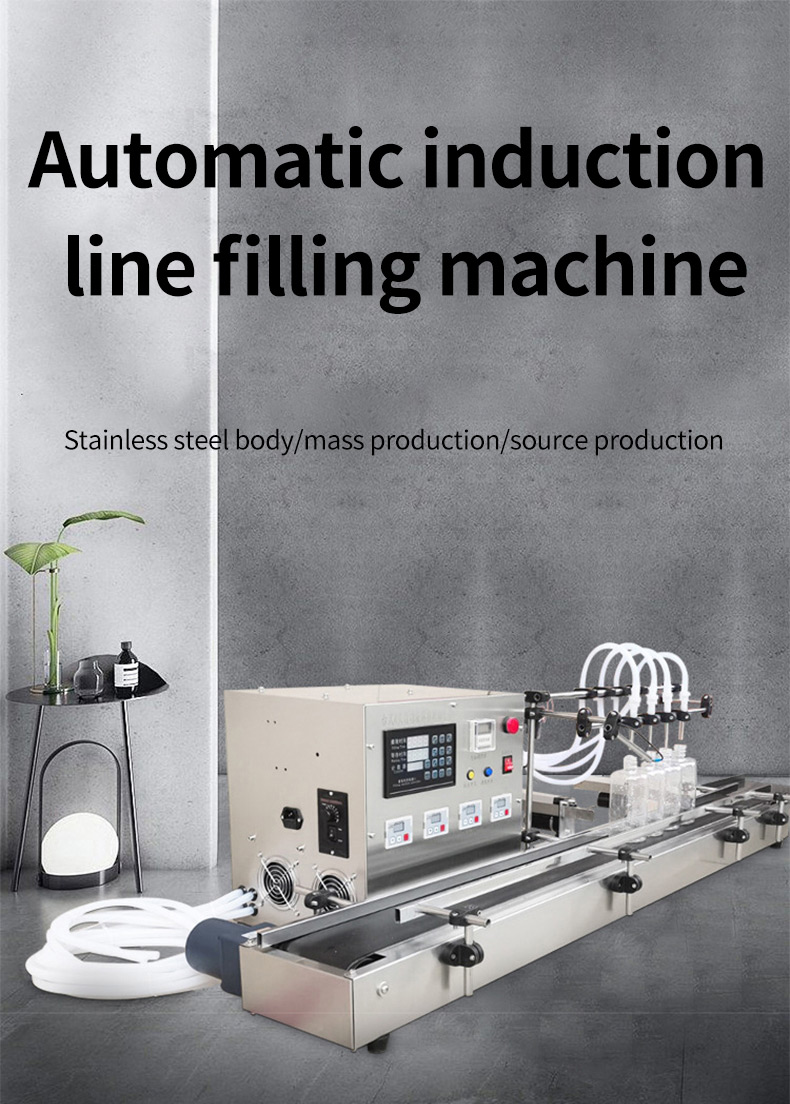

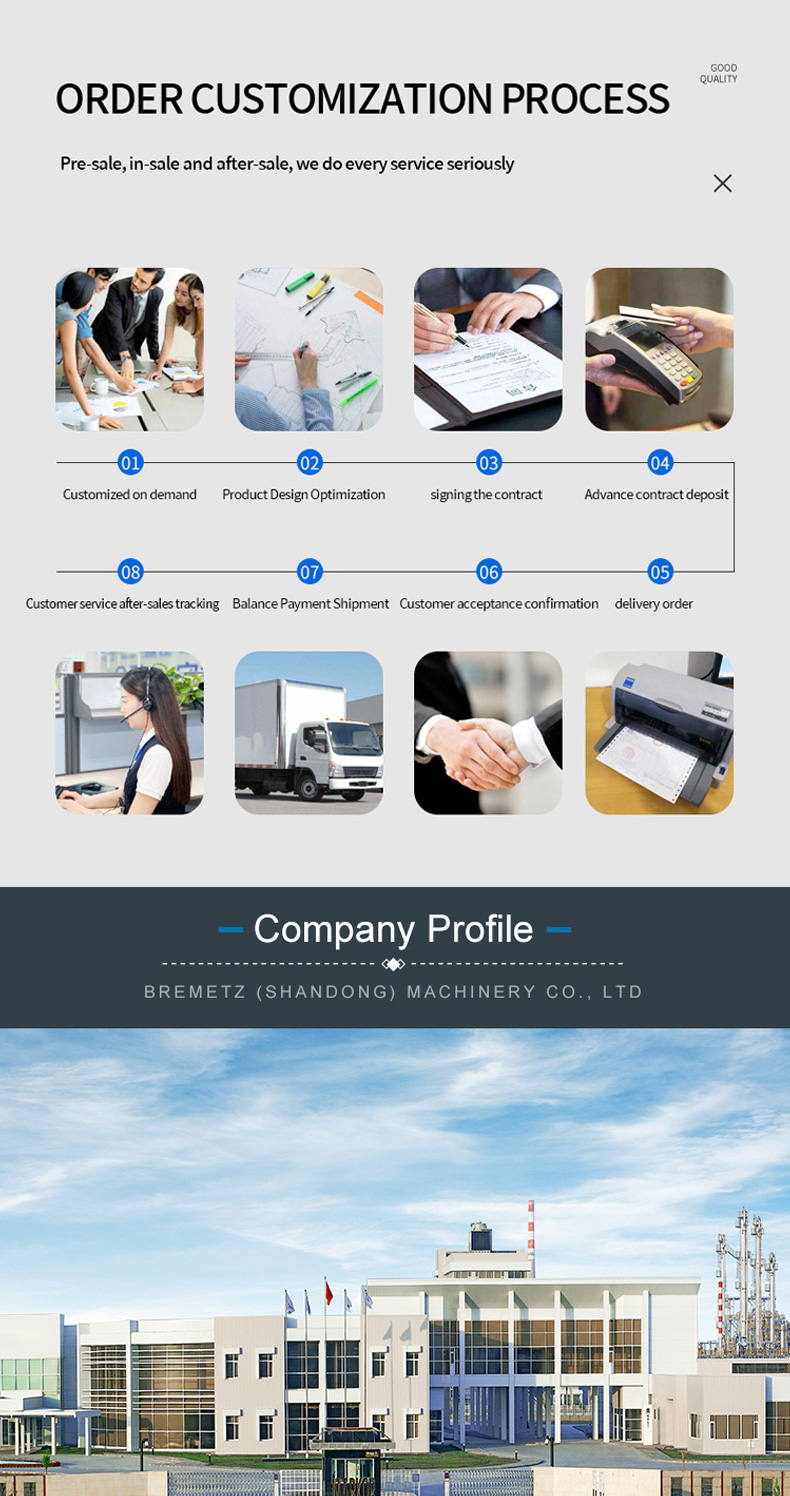

A. The filling machine is designed and improved based on similar foreign products, and some additional functions are added.

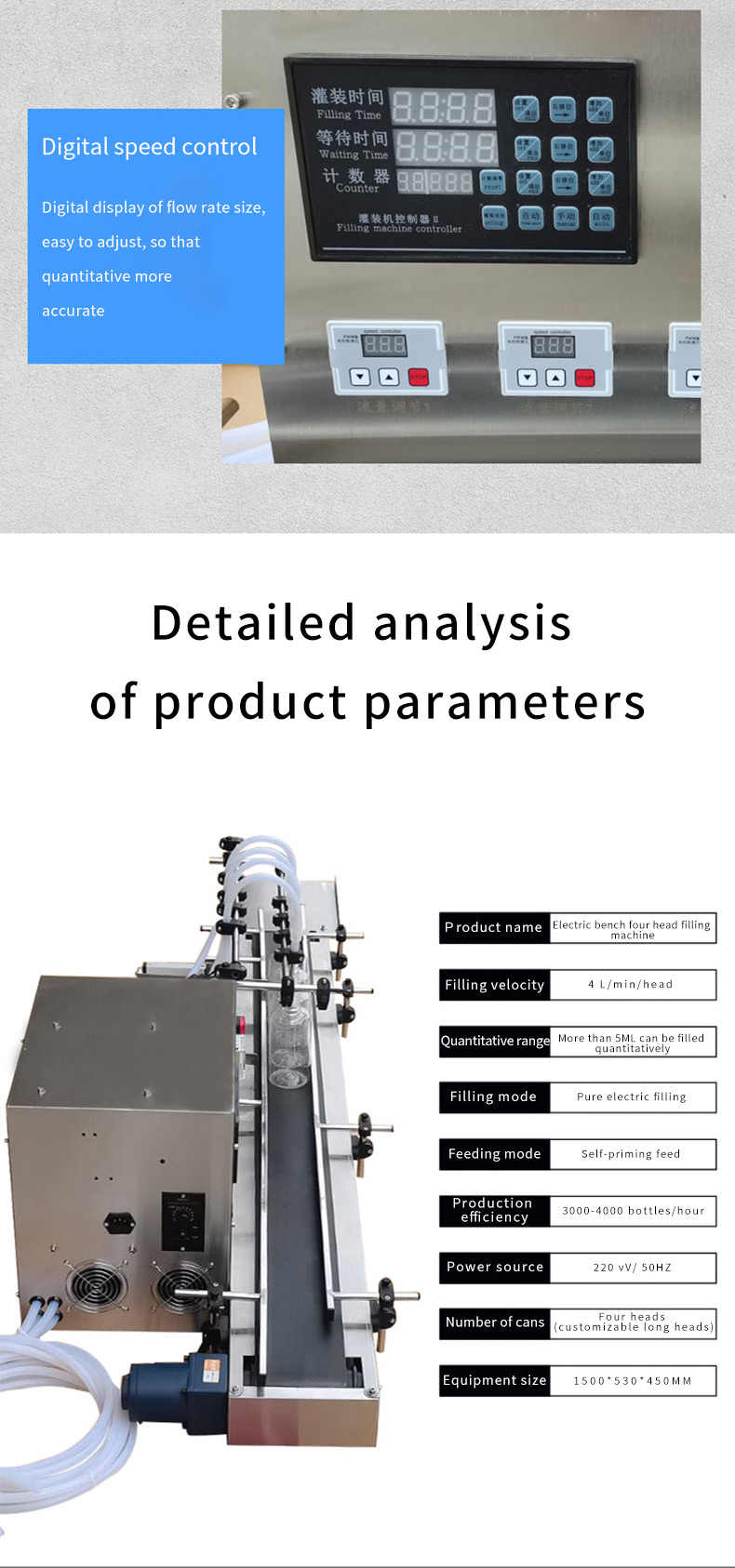

B. Make the product simpler and more convenient in terms of operation, precision error, installation adjustment, equipment cleaning, maintenance, etc.

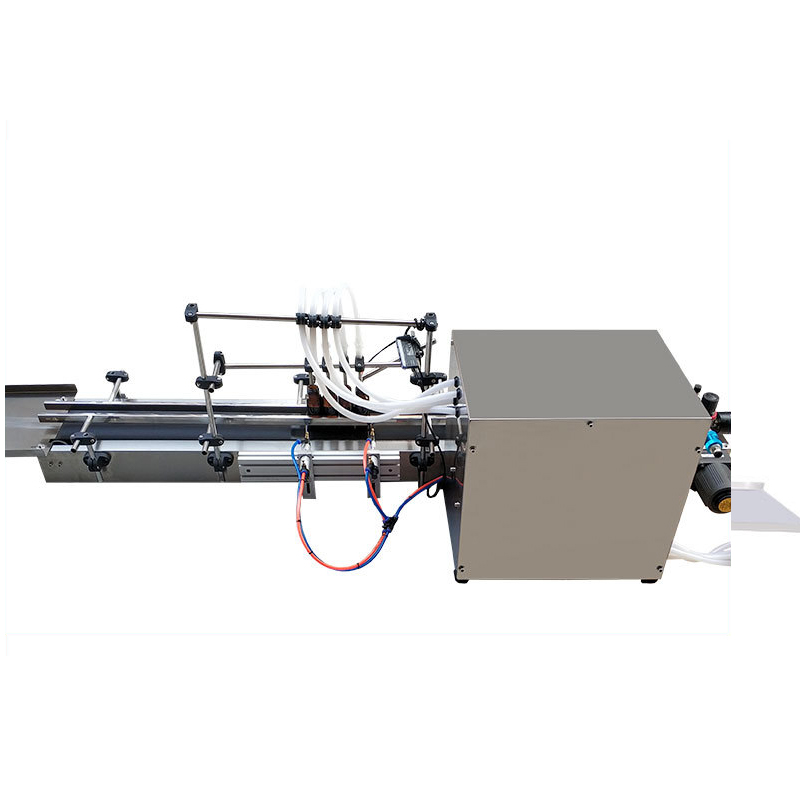

C. The machine has a compact and reasonable design, simple and beautiful appearance, and easy adjustment of the filling volume.

D. This machine has multiple filling heads, driven by multiple cylinders, to fill materials more quickly and accurately.

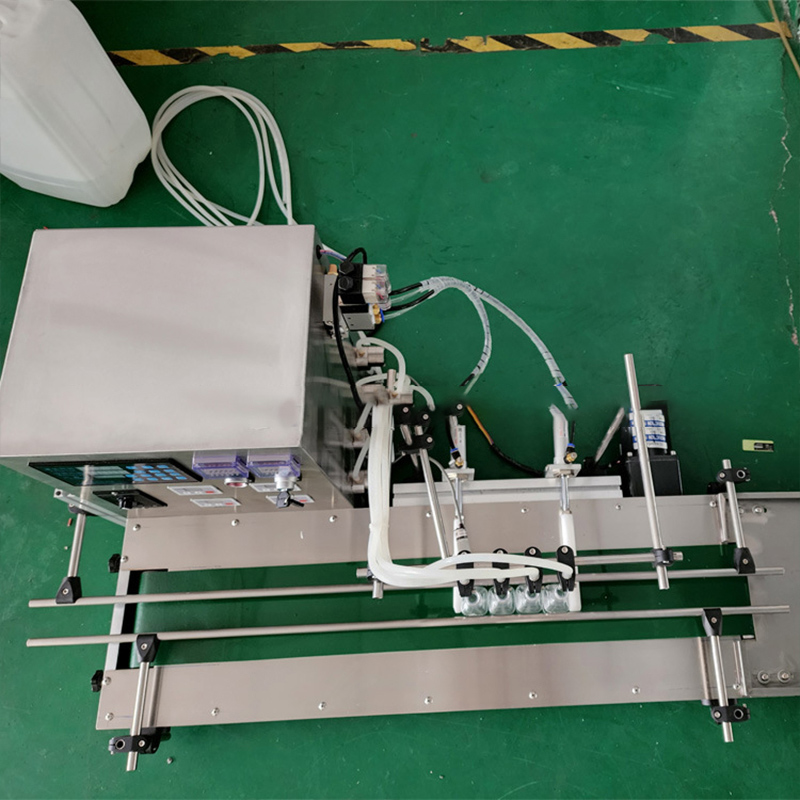

E. Using advanced pneumatic components and electronic control components, the performance is stable.

F. Material contact parts are made of 316L stainless steel.

G. The filling machine adopts Korean photo eye device, Taiwan PLC, touch screen, frequency converter and French electrical components.

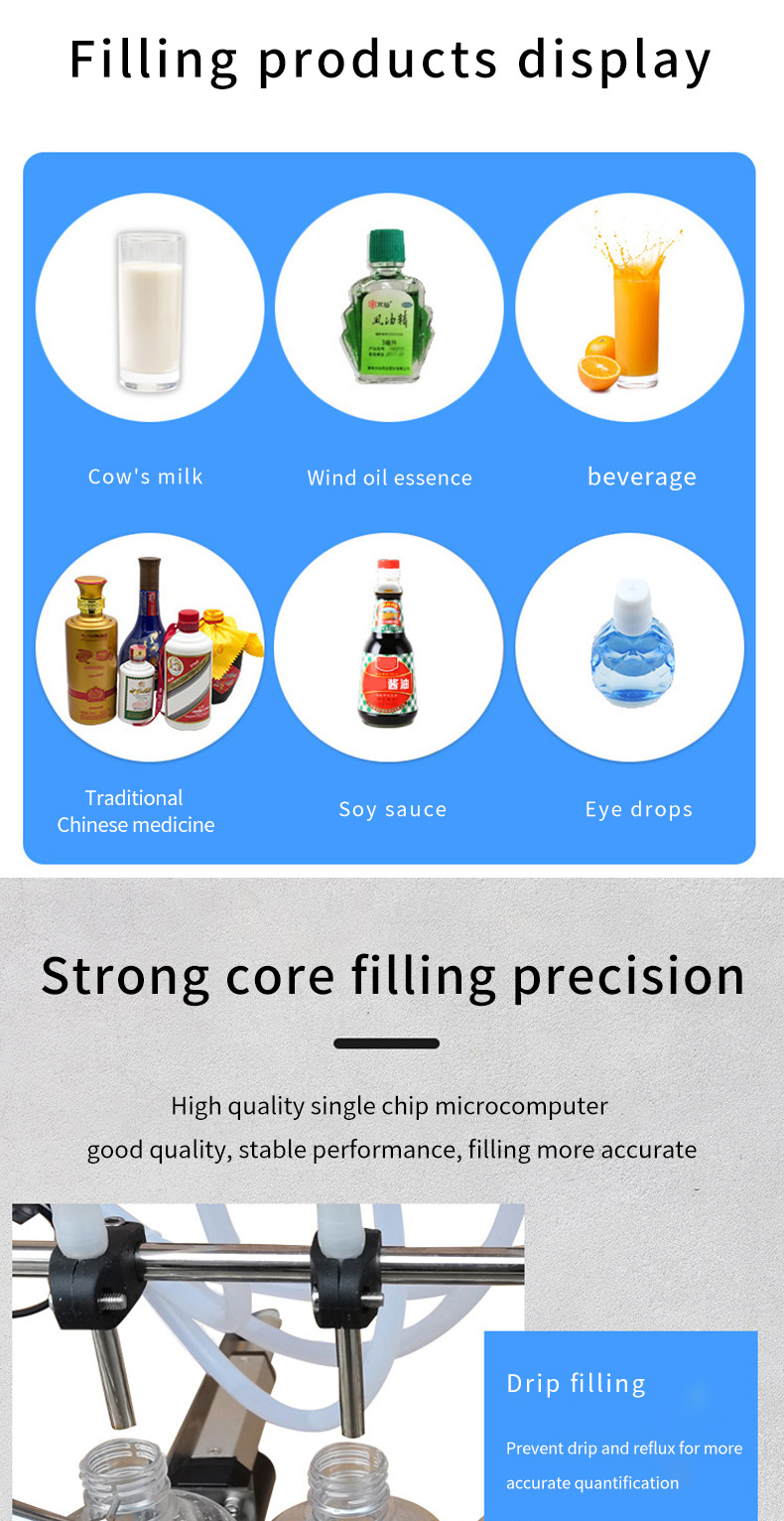

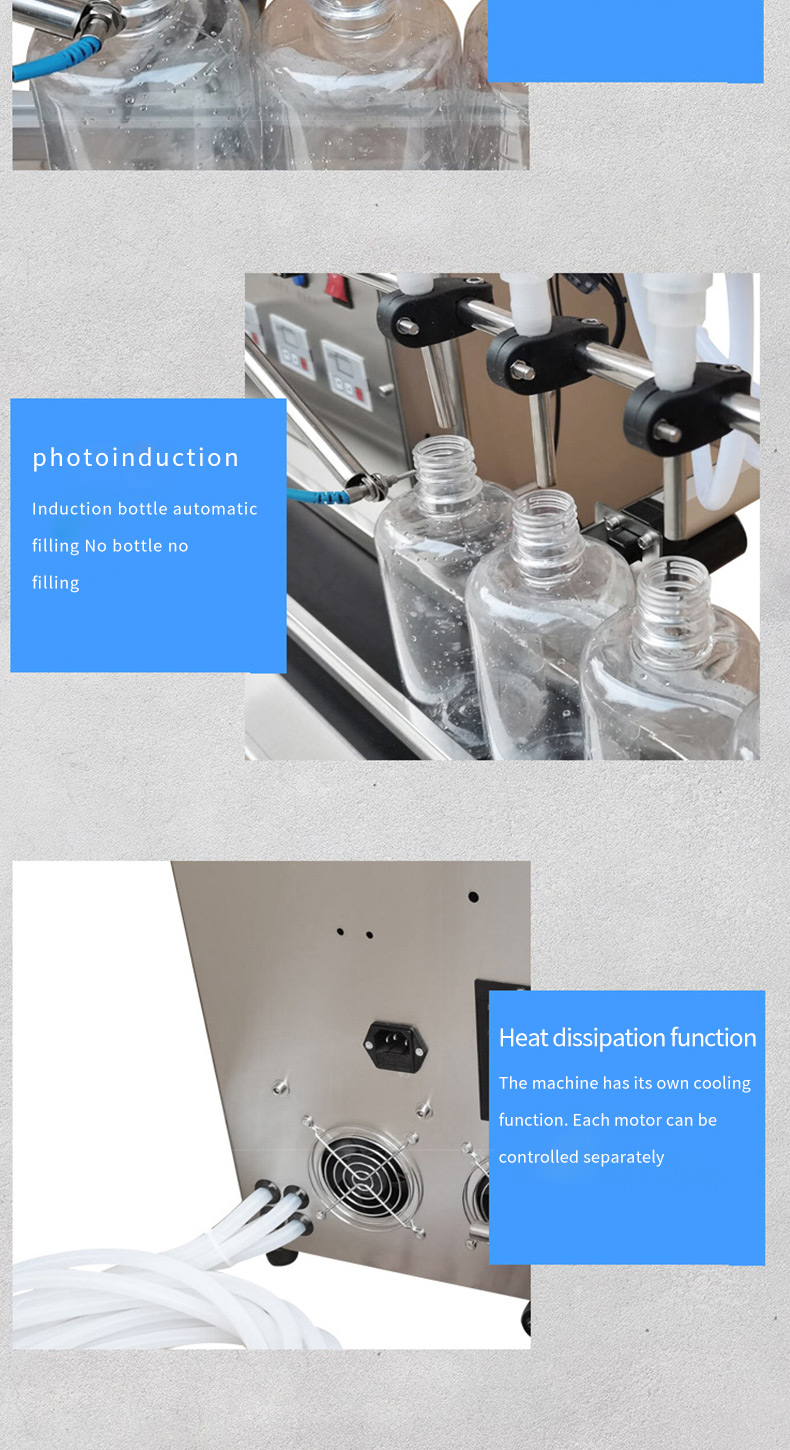

H. Easy to adjust, no filling without bottles, accurate filling amount and counting function.

I. Adopt drip-proof and wire-drawing filling bulkheads, a filling lifting system to prevent high-foaming products, a positioning system and a liquid level control system to ensure bottle mouth positioning.

Excellent accessories are available, and the inlet pipe is filled several times in the cleaning solution until the cleaning is complete. This series of filling machine is plunger type filling machine, self-priming filling, the material is driven by the cylinder piston to extract the material into the metering cylinder, and then the piston is driven by the pneumatic tube into the container, the filling amount is determined by adjusting the cylinder stroke.