Multifunctional liquid packaging machine

1. Multiple packaging forms: It can realize different packaging forms, such as bag packaging, bottle packaging, canned packaging, etc., to meet the diverse needs of different products and customers.

2. Multiple packaging specifications: The packaging capacity and size can be flexibly adjusted within a certain range. Simply set the parameters to adapt to the packaging of liquid products of various specifications.

3. With auxiliary functions: In addition to the basic filling and sealing functions, it may also be equipped with auxiliary functions such as labeling, coding, metering, and detection.

4. High-speed packaging: With a high packaging speed, it can greatly improve production efficiency and effectively reduce the packaging cost of unit products in large-scale production.

5. Accurate measurement: Equipped with a high-precision metering device, it can accurately control the filling volume of the liquid to ensure that the volume or weight of the liquid in each package meets the set standards.

6. Intelligent control: Through advanced sensors and control systems, various parameters in the packaging process can be monitored and fed back in real time, and automatically adjusted and optimized to ensure the stability of packaging quality.

Multifunctional liquid packaging machine uses a precise metering system to accurately inject liquid materials into the packaging container according to the set volume, and then uses the sealing system to seal the packaging container to complete the liquid packaging process. During the entire process, the control system coordinates the actions of each component to ensure the accuracy and efficiency of packaging.

Model: BLMC1000

Bag making width: 50-150mm

Packing speed: 2000 bags/hour

Bag length: 50-150mm

Dimensions: 860*780*1780mm

Packing capacity: 50-500ml

Overall weight: 300kg

Finished product in one machine Automatic fast bag making.

Meet industrial needs, rapid prototyping completes bag making, well adjusted, zero error rate can support a variety of mold customization.

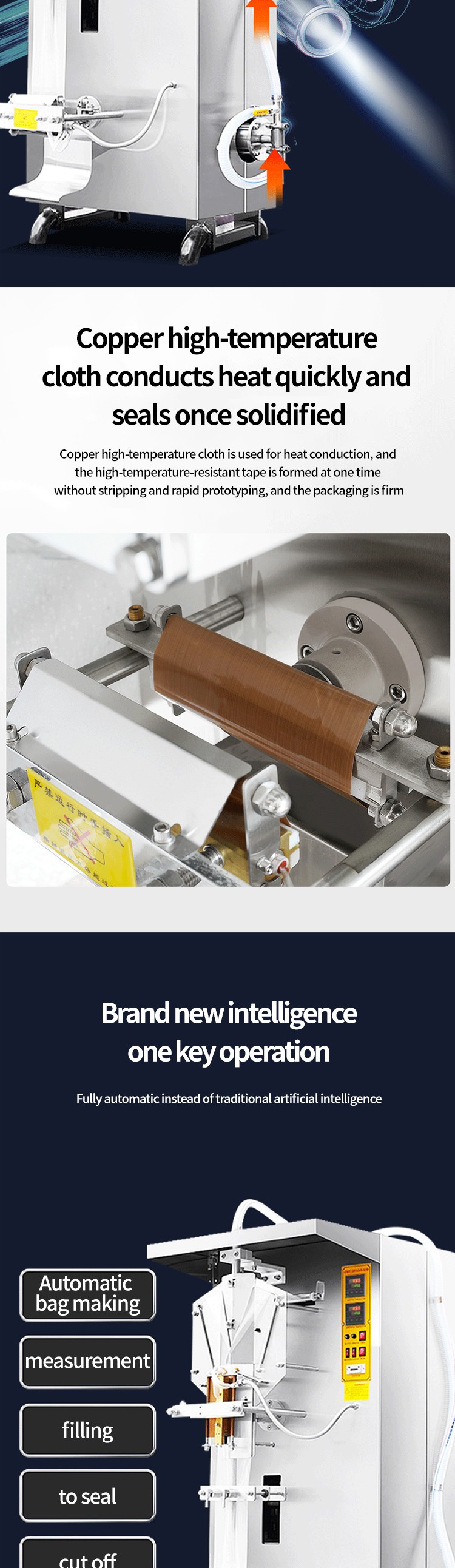

High quality suction metering pump.

Fast suction, meet industrial needs, no delay, no slow down, with check valve device, stop and no return.

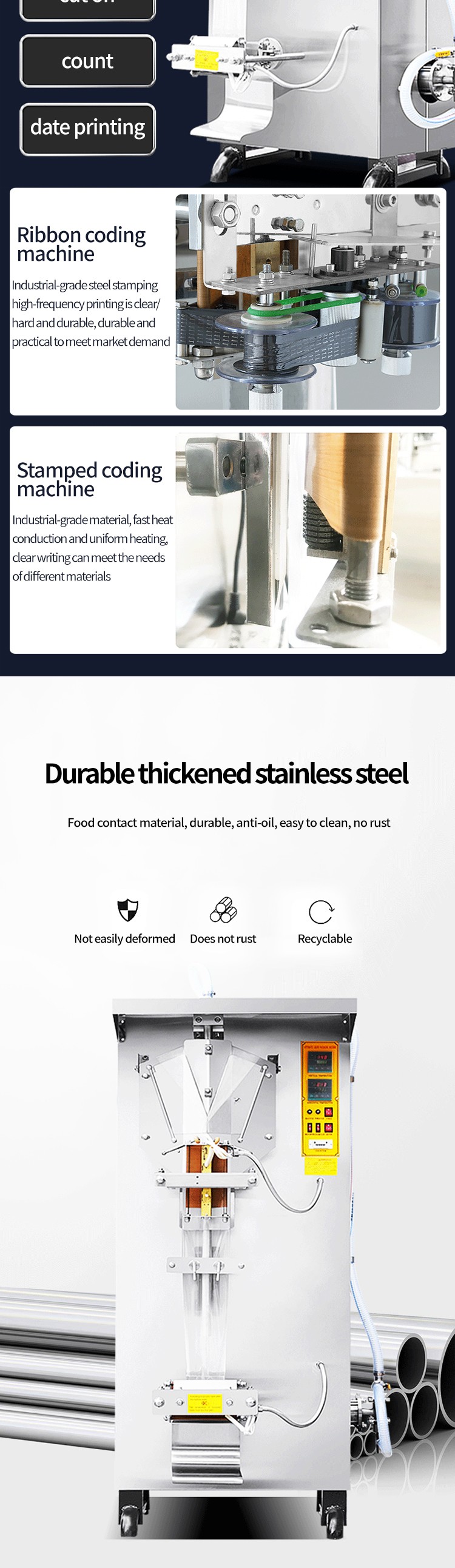

Copper high-temperature cloth is used for heat conduction, and the high-temperature-resistant tape is formed at one time without stripping and rapid prototyping, and the packaging is firm.

Brand new intelligence one key operation,Fully automatic instead of traditional artificial intelligence.

Multiple packaging forms and specifications: Supports multiple packaging forms such as bags, bottles, cans, etc., and the packaging specifications can be flexibly adjusted, ranging from a few milliliters to several liters, to meet the diverse needs of different products and customers. For example, for small doses of oral liquid medicines, 5 milliliters or 10 milliliters of bottle packaging can be used; for large packages of edible oil, 5 liters or 10 liters of canned packaging can be selected.

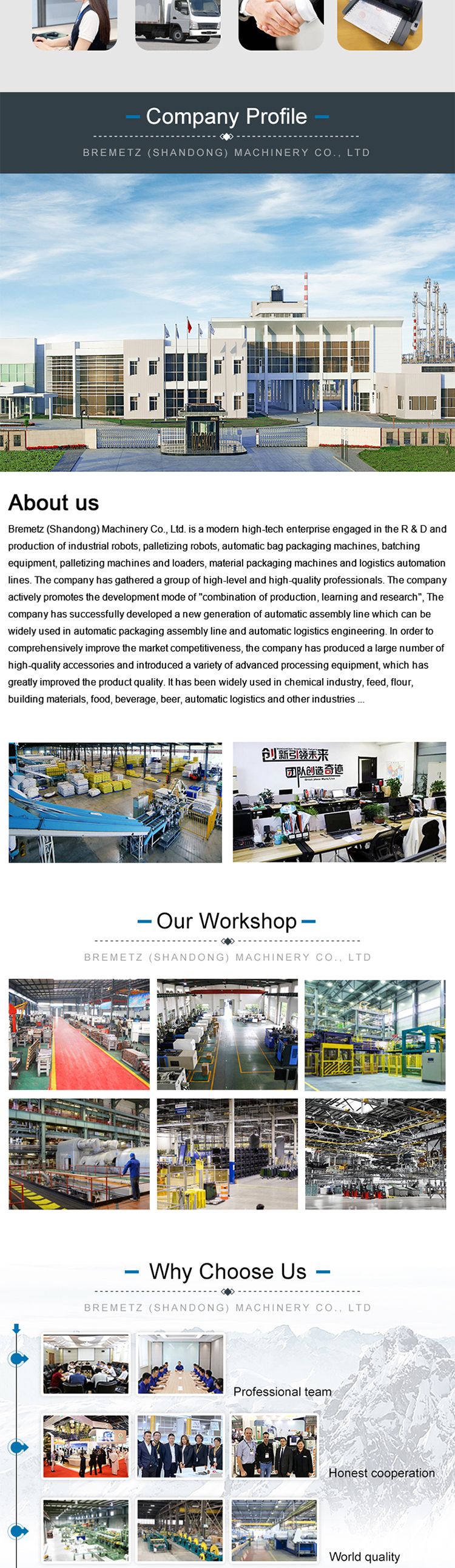

control Panel,Intelligent temperature control meter and button design make your operation easier and more convenient

Stainless Steel Film Rod,Real materials, stable and durable.

Pull bag motor,Pure copper movement lasts longer.

We provide customized services according to the special needs of customers. For example, we can design and modify the equipment according to the specific shape and size of packaging containers or special packaging process requirements; we can add special functional modules such as gas filling and vacuum packaging to meet the packaging needs of different products.

Warranty period: Generally, the product is warranted for one year from the date of qualified commissioning. Within this year, if the equipment is damaged due to non-human factors, the manufacturer will repair it for the customer free of charge.

Warranty scope: Covers the main components of the equipment such as mechanical parts, electrical systems, and control systems. However, for wearing parts such as seals, belts, filter elements, etc., the warranty period may be shorter or determined according to specific usage conditions.

Remote support: Provide customers with remote technical support through telephone, email, video calls, etc. When customers encounter problems, they can communicate with technicians in a timely manner. The technicians will analyze and guide the situation described by the customer to help customers solve the problem.

Upgrade service: With the continuous development of technology and changes in customer needs, manufacturers will launch equipment upgrade solutions in a timely manner to provide customers with equipment software, hardware and other aspects of upgrade services, so that customers' equipment can always maintain good performance and competitiveness, and can meet new production requirements.