Precise and efficient liquid packaging machine

1. The use of advanced electronic metering technology, high-precision flowmeters, etc. can accurately measure liquids to ensure that the packaging capacity error of each bag or bottle is extremely small.

2. The precise control system and stable mechanical transmission structure ensure the stability of parameters such as flow rate and pressure of the liquid during the packaging process.

3. The structural design and control system of the equipment enable rapid adjustment and conversion when changing different packaging specifications, packaging containers or liquid products.

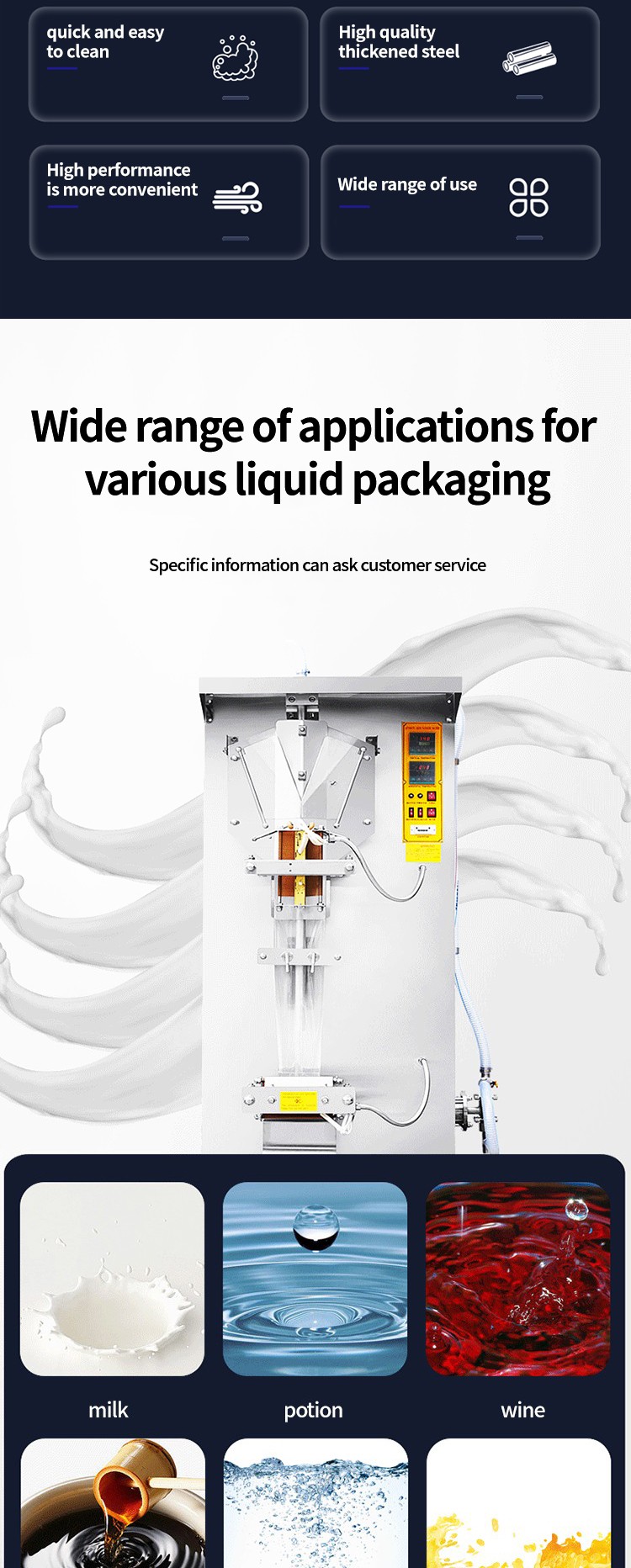

4. It can adapt to various liquids of different properties, and achieve accurate packaging of various liquids by adjusting the metering system, conveying pipelines and packaging components.

5. It supports multiple packaging forms, can also realize different sealing methods, and can customize special packaging forms according to customer needs.

Precise and Efficient Liquid Packaging Machine is the core equipment in the field of modern liquid product packaging. With its excellent characteristics, it empowers the production and development of many industries.

With cutting-edge metering technology and intelligent compensation algorithms, the packaging volume of each bag or bottle can be accurately controlled for all types of liquids, regardless of their viscosity, to ensure consistency and standardization of product quality.

The high-efficiency variable frequency speed regulating motor and optimized mechanical transmission structure are adopted, the packaging process is closely connected, the operation speed is fast and stable, and the packaging quantity can reach dozens or even hundreds of bags per minute.

Model: BLMC1000

Bag making width: 50-150mm

Packing speed: 2000 bags/hour

Bag length: 50-150mm

Dimensions: 860*780*1780mm

Packing capacity: 50-500ml

Overall weight: 300kg

It can adapt to a variety of liquids with different properties, from low-viscosity alcohol and fruit juice to medium-viscosity emulsions and edible oils, and then to high-viscosity glue and jam, etc. By adjusting the metering system, conveying pipelines and packaging components, etc., it can achieve precise packaging of a variety of liquids.

The large-size touch screen is equipped with a simple and easy-to-understand operation interface. Operators can quickly get started without complex professional training and easily complete parameter settings, operation monitoring and troubleshooting.

The equipment has a reasonable structure design, is easy to disassemble and clean, and is simple and easy to perform regular maintenance, effectively reducing the equipment operation and maintenance costs.

Equipped with complete safety protection devices, including overload protection, leakage protection, protective door locking, emergency stop button, etc., to protect the personal safety of operators in all aspects.

The parts that come into contact with liquids are made of food-grade or medical-grade materials to eliminate the risk of liquid contamination from the source and ensure product quality and safety.