Automatic Boxopener

1. Precise cutting and opening: Equipped with high-precision cutting devices and unpacking mechanisms, it can accurately cut and open the boxes. For some boxes containing fragile or high-precision products, the automatic unpacking machine can accurately open the boxes to avoid product losses caused by improper unpacking.

2. Continuous and stable operation: The equipment uses high-quality components and advanced manufacturing processes to ensure long-term continuous and stable operation. The key mechanical transmission components and electrical components have good durability and reliability and can withstand high-intensity workloads.

3. Automatic feeding and unpacking process: A fully automated process from box feeding to unpacking is realized. After the box is automatically transported to the working area of the unpacking machine, the equipment will automatically complete a series of actions such as positioning, cutting, and opening without manual intervention.

4. Intelligent control and adjustment: Using advanced control systems, it can automatically adjust the unpacking parameters according to the type and state of the box.

5. Comprehensive safety protection mechanism: Equipped with complete safety protection devices, such as emergency stop buttons, protective door sensors, light curtain protection, etc. The emergency stop button can quickly stop the equipment in an emergency to ensure the safety of the operator.

6. Simple operation interface: The equipment is usually equipped with a simple and intuitive operation interface, which allows operators to easily get started. Basic operations such as starting, stopping, and parameter setting of the equipment can be completed through the touch screen or simple button operation.

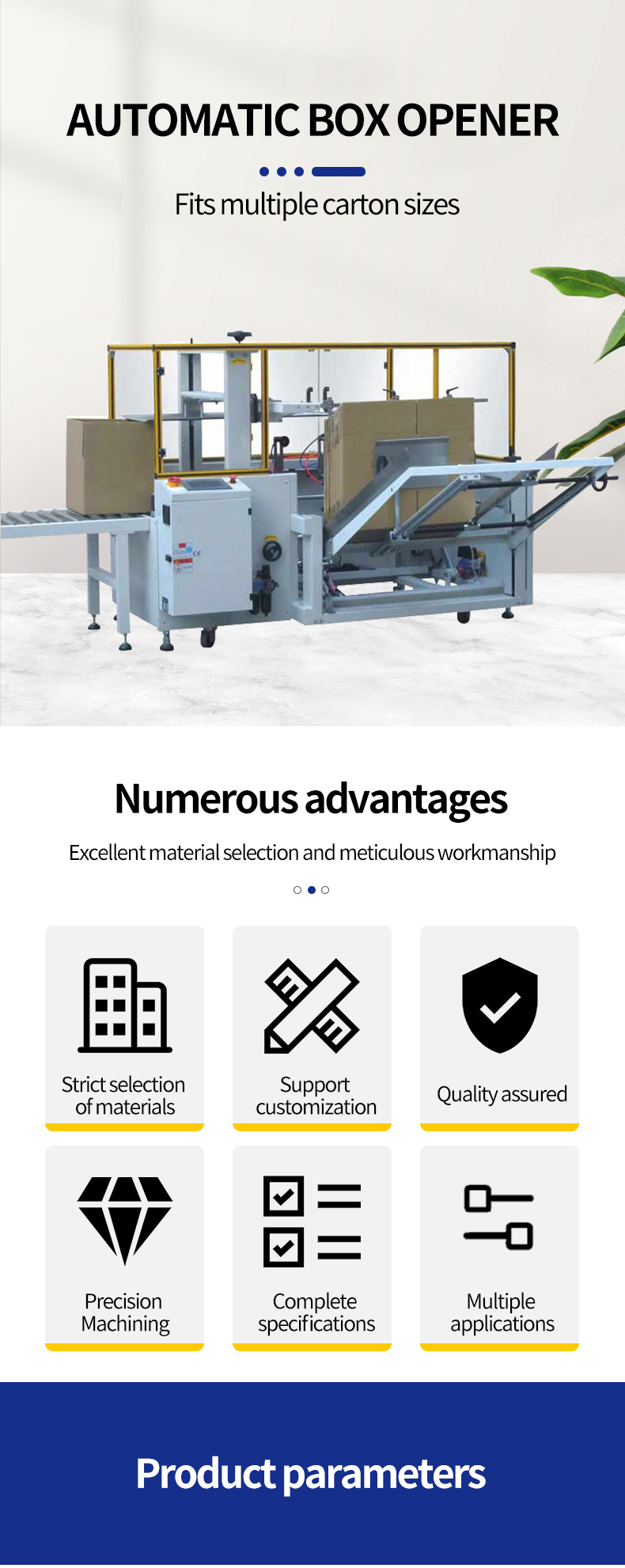

Automatic Boxopener is an automated device designed for efficient and accurate box opening. It is widely used in logistics, warehousing, manufacturing, e-commerce and other industries. Through advanced technology and intelligent design, it effectively solves the problems of low efficiency and easy damage of traditional manual box opening, and has become an indispensable key equipment in the modern packaging processing link.

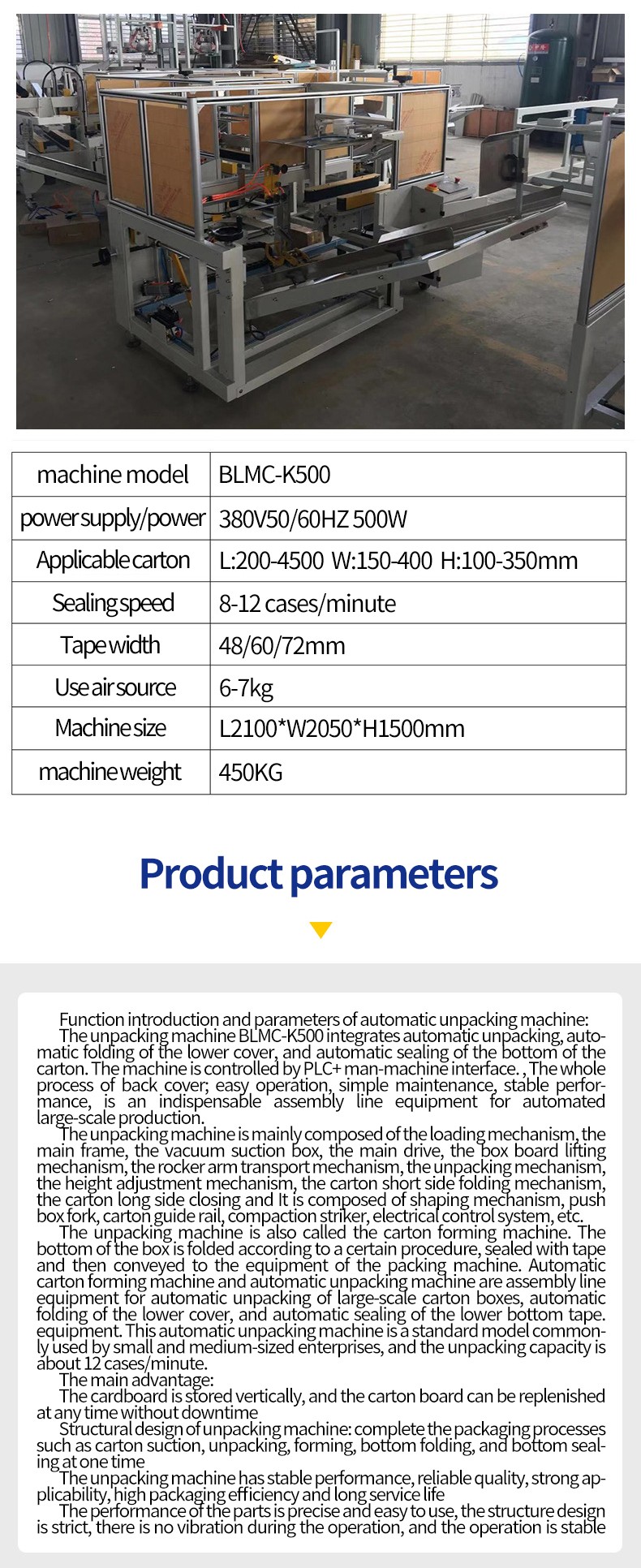

machine model:BLMC-K500 power supply/power:380V50/60HZ 500W Applicable carton:L:200-4500 W:150-400 H:100-350mm Sealing speed:8-12 cases/minute Tape width:48/60/72mm Use air source:6-7kg Machine size:L2100*W2050*H1500mm machine weight:450KG

The unpacking machine is mainly composed of the loading mechanism, the main frame, the vacuum suction box, the main drive, the box board lifting mechanism, the rocker arm transport mechanism, the unpacking e unpacking mechanism, the height adjustment mechanism, the carton short side folding mechanism, the carton long side closing and It is composed of shaping mechanism, push box fork, carton guide rail, compaction striker, electrical control system, etc.

The unpacking machine is also called the carton forming machine. The bottom of the box is folded according to a certain procedure, sealed with tape and then conveyed to the equipment of the packing machine. Automatic carton forming machine and automatic unpacking machine are assembly line equipment for automatic unpacking of large-scale carton boxes, automatic folding of the lower cover, and automatic sealing of the lower bottom tape. equipment. This automatic unpacking machine is a standard model common- ly used by small and medium-sized enterprises, and the unpacking capacity is about 12 cases/minute.

The main advantage: The cardboard is stored vertically, and the carton board can be replenished at any time without downtime.

The unpacking machine has stable performance, reliable quality, strong ap- plicability, high packaging efficiency and long service life The performance of the parts is precise and easy to use, the structure design is strict, there is no vibration during the operation, and the operation is stable.

Application areas:

Logistics and warehousing industry, in logistics centers and warehouses, Automatic Boxopener is widely used to handle various cargo boxes. Whether it is e-commerce parcels, wholesale commodity boxes or a large number of packaging boxes in the logistics transfer process, they can be opened quickly and accurately by automatic box openers, improving the efficiency of sorting and handling of goods.

Manufacturing industry, on the production line of manufacturing industry, the unpacking link after product packaging requires efficient and accurate equipment. Automatic box openers can handle product packaging boxes of different types and sizes, ensuring that the products are not damaged during the unpacking process, and meet the unpacking needs of large-scale production.

Commercial and retail industry, in the commercial and retail fields, such as supermarkets, shopping malls, warehouses or distribution centers, Automatic Boxopener is used to handle commodity packaging boxes. For commercial environments with frequent inbound and outbound shipments, fast unpacking can speed up the speed of goods on the shelves and improve operational efficiency.

E-commerce industry, the e-commerce industry has extremely high requirements for the speed and accuracy of cargo handling. Automatic box openers play an important role in e-commerce warehouses. They can quickly process a large number of express parcel boxes, improve order processing efficiency, and reduce consumer waiting time.

We have a professional after-sales maintenance team that can respond promptly to user fault reports. Our maintenance personnel have rich maintenance experience and professional knowledge and can quickly diagnose and solve equipment problems.