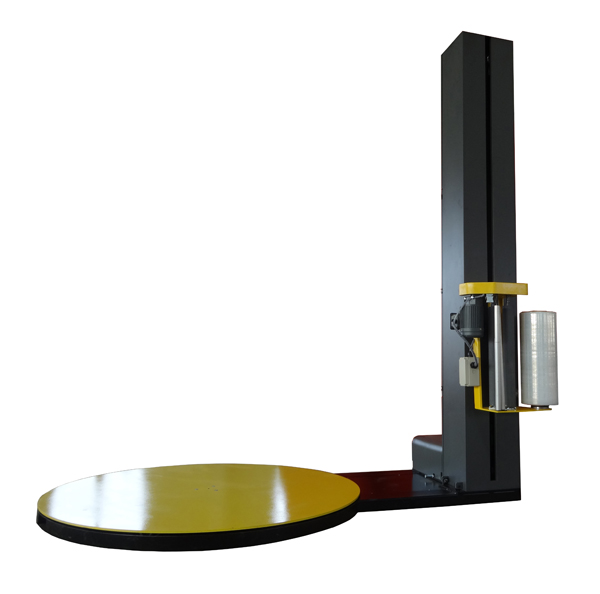

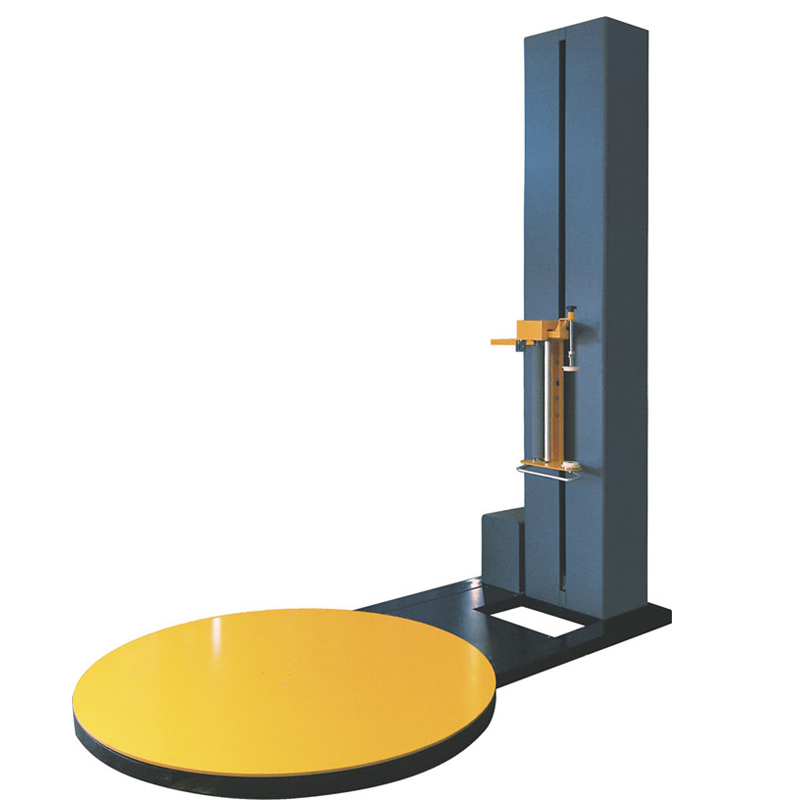

Stretch film packaging machine

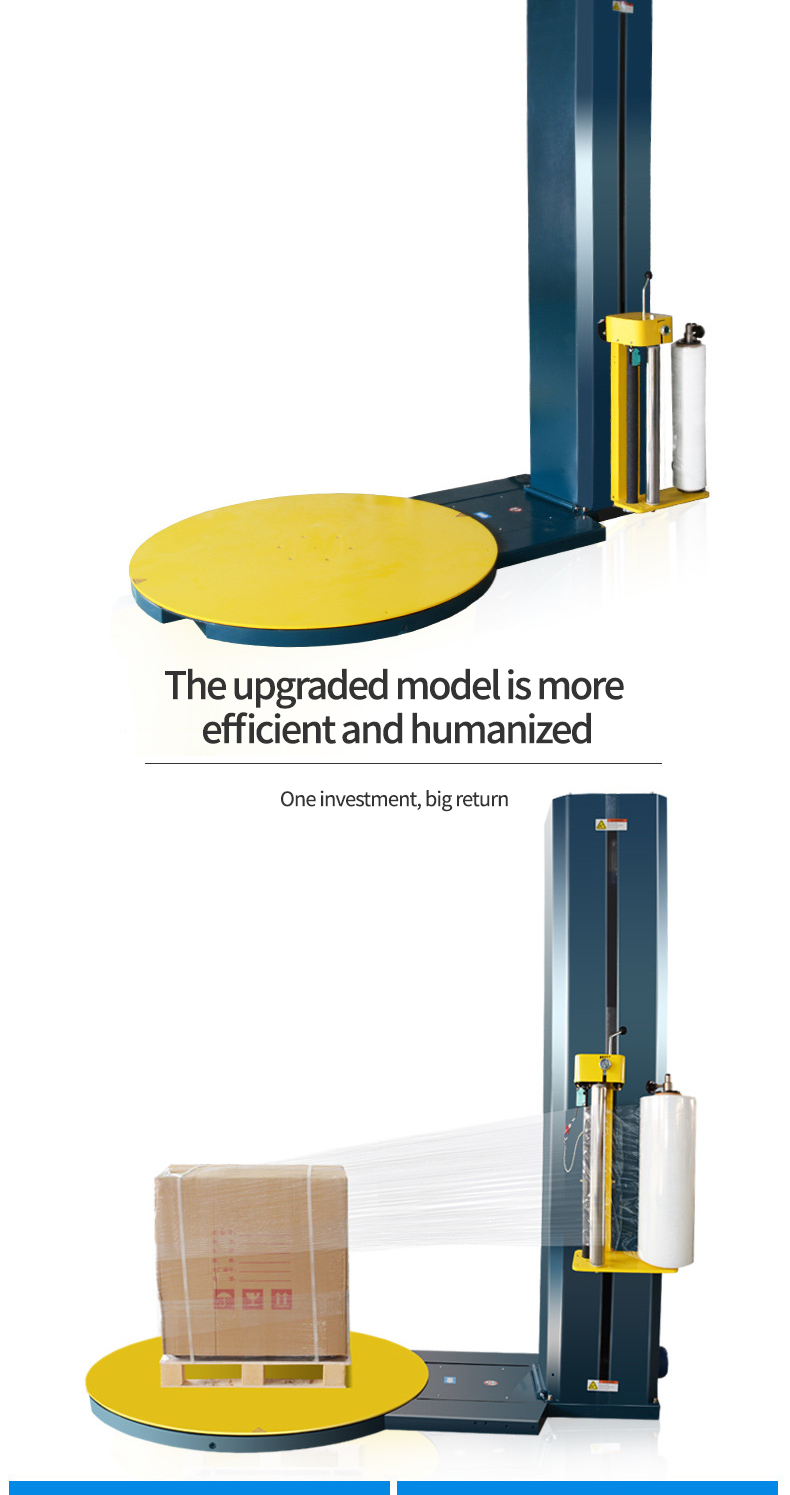

1. Fast packaging speed: Stretch film packaging machine has efficient packaging capabilities. With advanced mechanical transmission and automatic control system, it can complete the stretch film packaging of products in a short time.

2. Continuous and stable operation: It can work continuously for a long time. In a stable working environment, its performance is reliable and the packaging speed will not be affected by frequent starting and stopping.

3. Tight fit and stable packaging: Packaging products with stretch film can make the film fit tightly on the surface of the product.

4. Good protective performance: Stretch film can provide multi-faceted protection for products. It can resist the erosion of dust and moisture and reduce the impact of external factors on product quality.

5. Efficient stretch ratio: The machine can achieve a higher stretch ratio, which means that the ideal packaging effect can be achieved with less stretch film material.

6. Accurate material control: It has precise film conveying and cutting control functions. It can accurately control the amount of stretch film used according to the size and packaging requirements of the product to avoid material waste.

Stretch film packaging machine is an advanced mechanical equipment specially used for packaging various products with stretch film. It plays a key role in many industries such as modern logistics, manufacturing, warehousing, etc. By tightly wrapping the stretch film around the product or goods, it can achieve stable packaging, product protection, and facilitate handling and storage, effectively improving the efficiency and quality of the product packaging process.

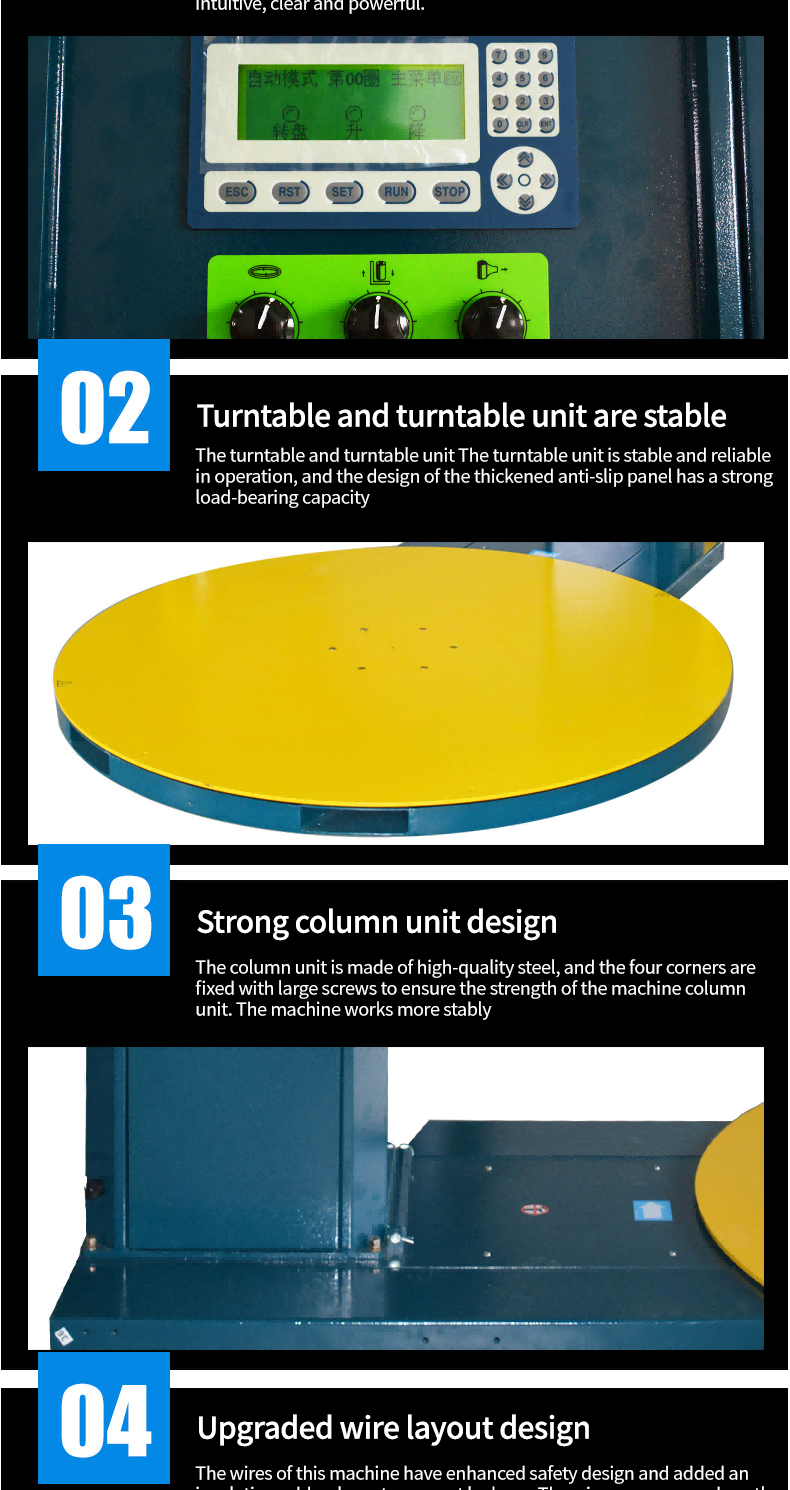

The equipment realizes a fully automated process from film conveying, product conveying positioning to stretching and winding, without the need for manual intervention in the complex operations of the packaging process, greatly improving packaging efficiency. Operators only need to set parameters on the operation panel and monitor the operating status of the equipment, reducing the workload and complexity of manual operation, and also reducing errors and defective rates caused by human factors.

Through precise stretch ratio control, product positioning and wrapping operations, we can ensure that the packaging quality of each product meets high standards. Stretch film can fit the product tightly, and both regular and irregular shaped items can be effectively wrapped, ensuring the stability and firmness of the packaging. This is of great significance for maintaining the integrity of the product and reducing damage during transportation and storage.

It has strong compatibility with product types, shapes and sizes as well as stretch film specifications, and can meet the packaging needs of different industries and products. Enterprises do not need to purchase multiple different packaging equipment for different products and film combinations, reducing equipment procurement costs and the complexity of production management. This wide adaptability allows the equipment to be flexibly applied in a variety of production scenarios, improving equipment utilization and return on investment.

The operation panel is concise and clear, and the function buttons are reasonably arranged, so the operator can easily set and adjust the operating parameters of the equipment. The control system of the equipment is intelligent and can automatically detect and handle some common problems, such as film breakage, product blockage, abnormal stretching, etc., and send alarms and prompts to the operator in time. This helps to improve the operating stability and production efficiency of the equipment, while also reducing the requirements for the professional skills of the operator, making it easier for the company to carry out personnel training and equipment operation management.

It is equipped with complete safety protection devices, such as emergency stop button, guardrail, overload protection, etc., to ensure the safety of operators during the operation of the equipment. At the same time, the structural design and manufacturing process of the equipment ensure its reliability in the long-term operation process, reduce equipment failures and downtime, and reduce the company's maintenance costs and production losses.

The higher stretching ratio saves stretch film materials, reduces packaging costs, and also reduces the generation of packaging waste. In addition, the equipment focuses on energy conservation during design and manufacturing, such as the use of energy-saving motors and optimized control systems, which reduces energy consumption and helps enterprises achieve green production and improve economic benefits.

We have a team of professional installation engineers who are experienced in the installation of Stretch film packaging machine. After the equipment is delivered to the customer, the installation team will quickly carry out the installation work according to the location and environmental conditions specified by the customer.

We have established a variety of customer feedback channels, including customer service hotlines, online customer service platforms, emails, suggestion boxes, etc., to ensure that any questions, suggestions or opinions from customers during the use of the equipment can be conveyed to us in a timely manner.