Tic-tac-toe packaging machine

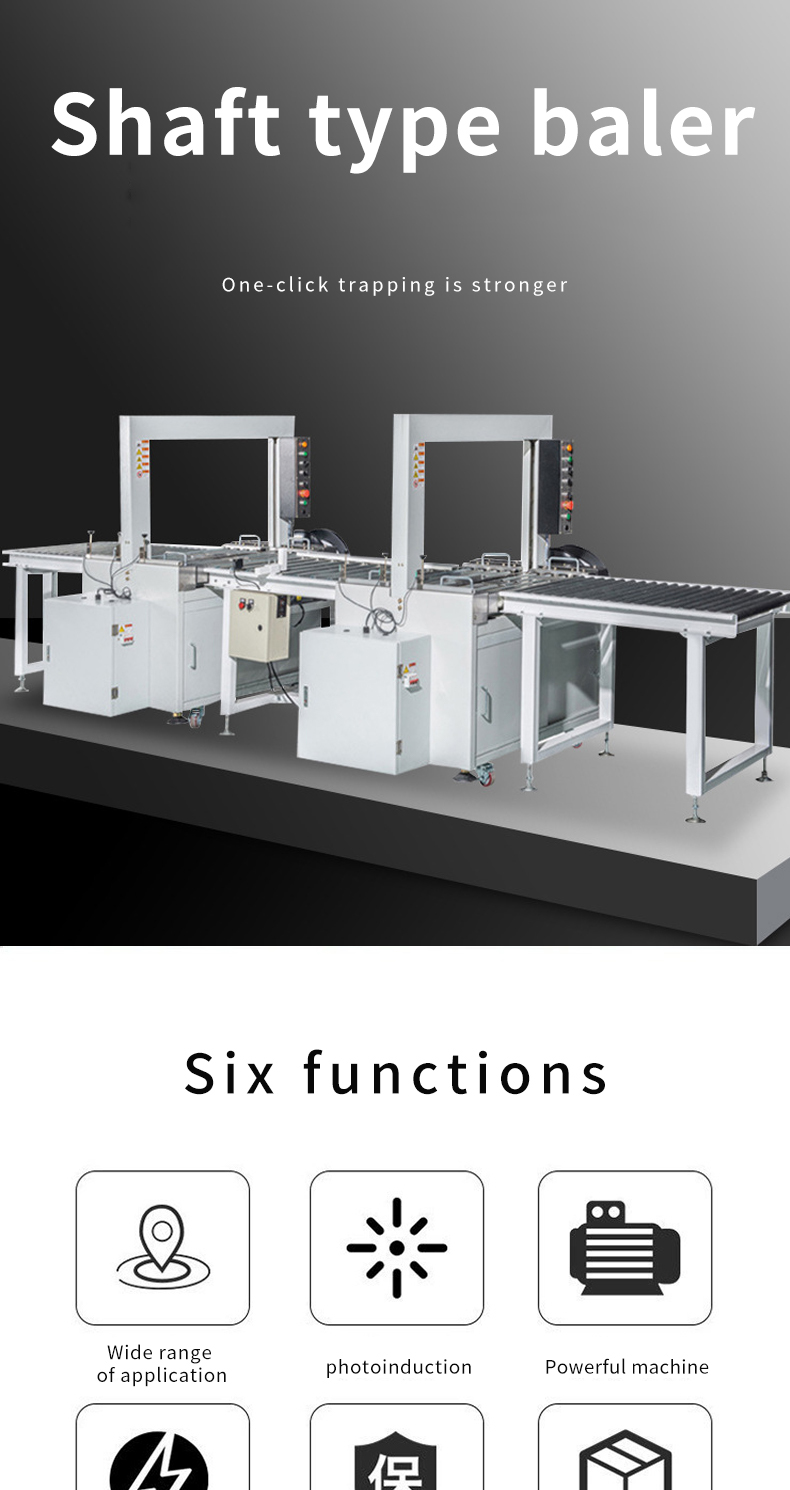

1. It can realize fast and continuous packaging operations, greatly improving production efficiency, especially suitable for large-scale production scenarios

2. It has a precise positioning system, which can ensure that the product is accurately placed in the predetermined position during the packaging process, making the packaging more neat and beautiful.

3. The use of advanced sealing technology can achieve a firm and tight seal, effectively preventing product leakage, deterioration and other problems.

4. Through reasonable tic-tac-toe layout and packaging structure design, the use of packaging materials can be minimized while ensuring that the product is fully protected

5. The packaging materials can be accurately cut and distributed according to the product size and packaging requirements, avoiding material waste and improving the utilization rate of packaging materials.

Tic-Tac-Toe Packaging Machine is mainly composed of material conveying system, packaging actuator, control system, frame and auxiliary devices. Its overall design concept is centered on efficient, accurate and stable packaging of tic-tac-toe products or similar block items.

The conveyor belt is made of food-grade rubber or polyurethane, which has good wear resistance, anti-static and anti-slip properties, ensuring that the Tic-Tac-toe products will not slip or be damaged during transportation.

The spiral track and vibrator inside the vibration plate are carefully designed to adjust the vibration frequency and amplitude according to the shape, size and weight of the product, so that the product can rise and be arranged neatly along the track.

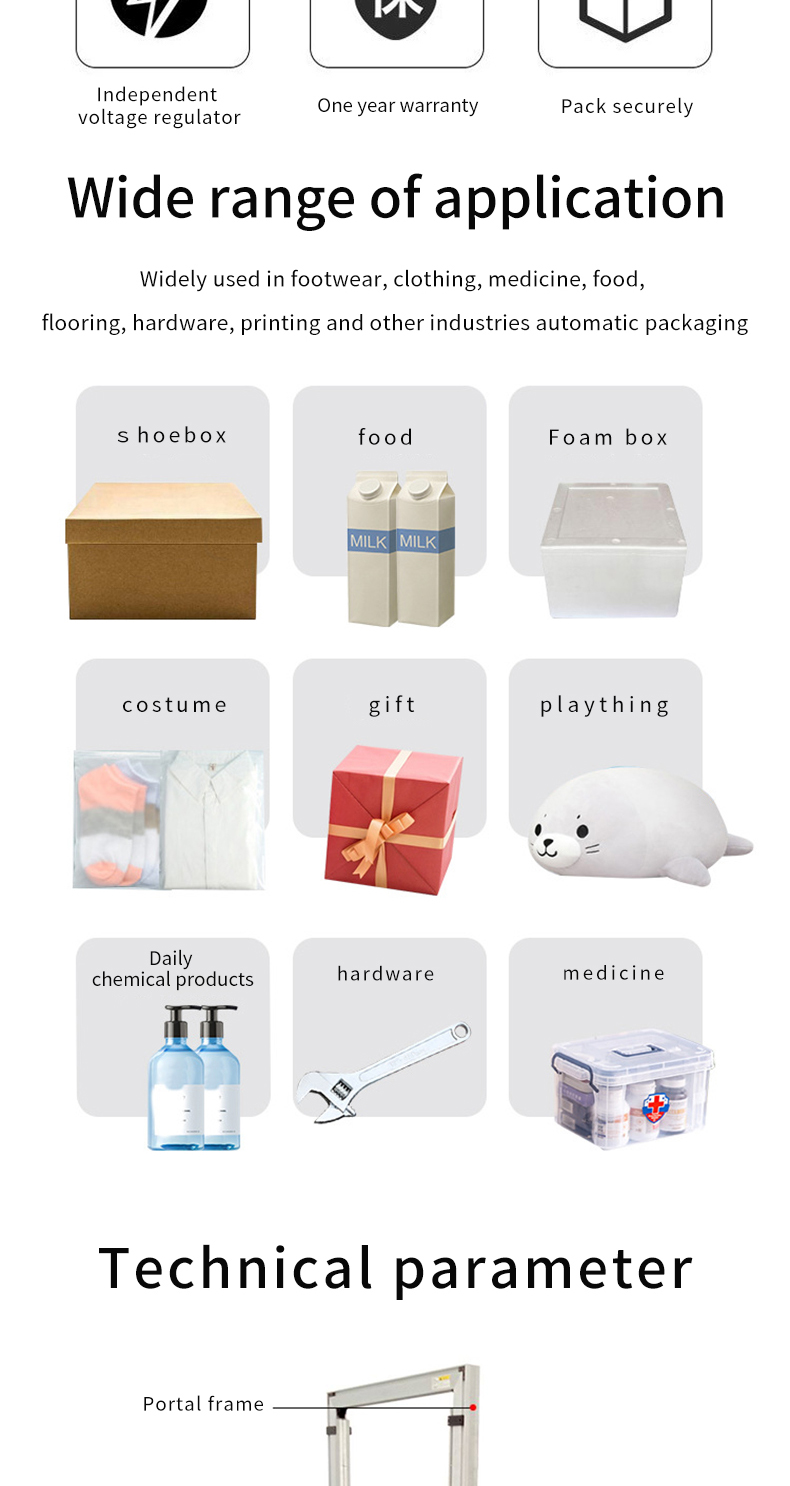

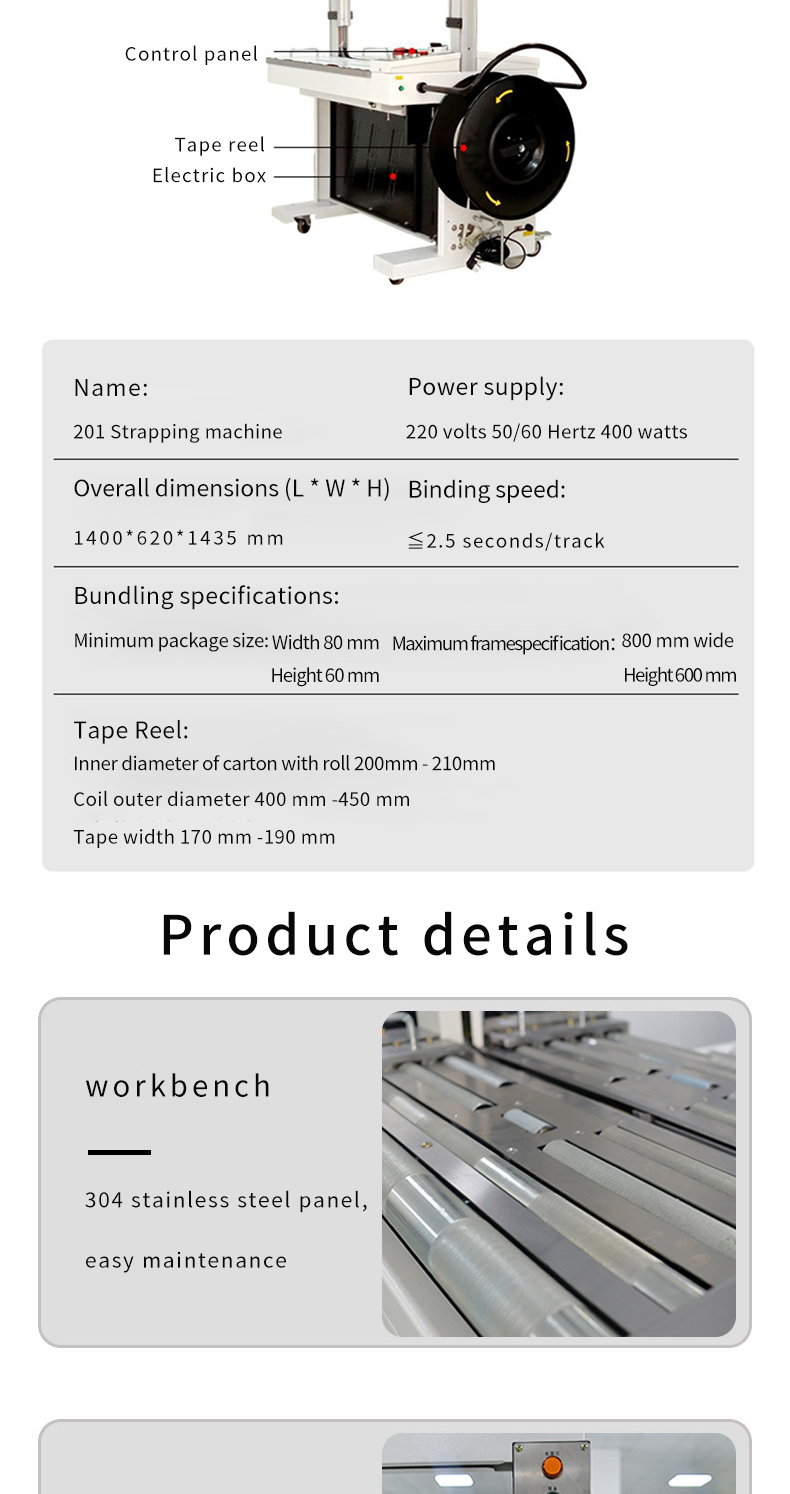

Name:201 Strapping machine

Power supply:220 volts 50/60 Hertz 400 watts

Overall dimensions (L*W*H) :1400*620*1435 mm

Binding speed:≤2.5 seconds/track

Bundling specifications:Minimum package size: Width 80 mm Maximum framespecification: 800 mm wide Height 60 mm Height 600 mm

Tape Reel:Inner diameter of carton with roll 200mm - 210mm,Coil outer diameter 400 mm -450 mm,Tape width 170 mm -190 mm

The origami device consists of multiple robotic arms, folding plates and guide rails. Driven precisely by the control system, the robotic arms fold the packaging paper from both sides to the middle according to the preset origami program to form the upper and lower and side packaging shapes of the Tic-Tac-Toe product.

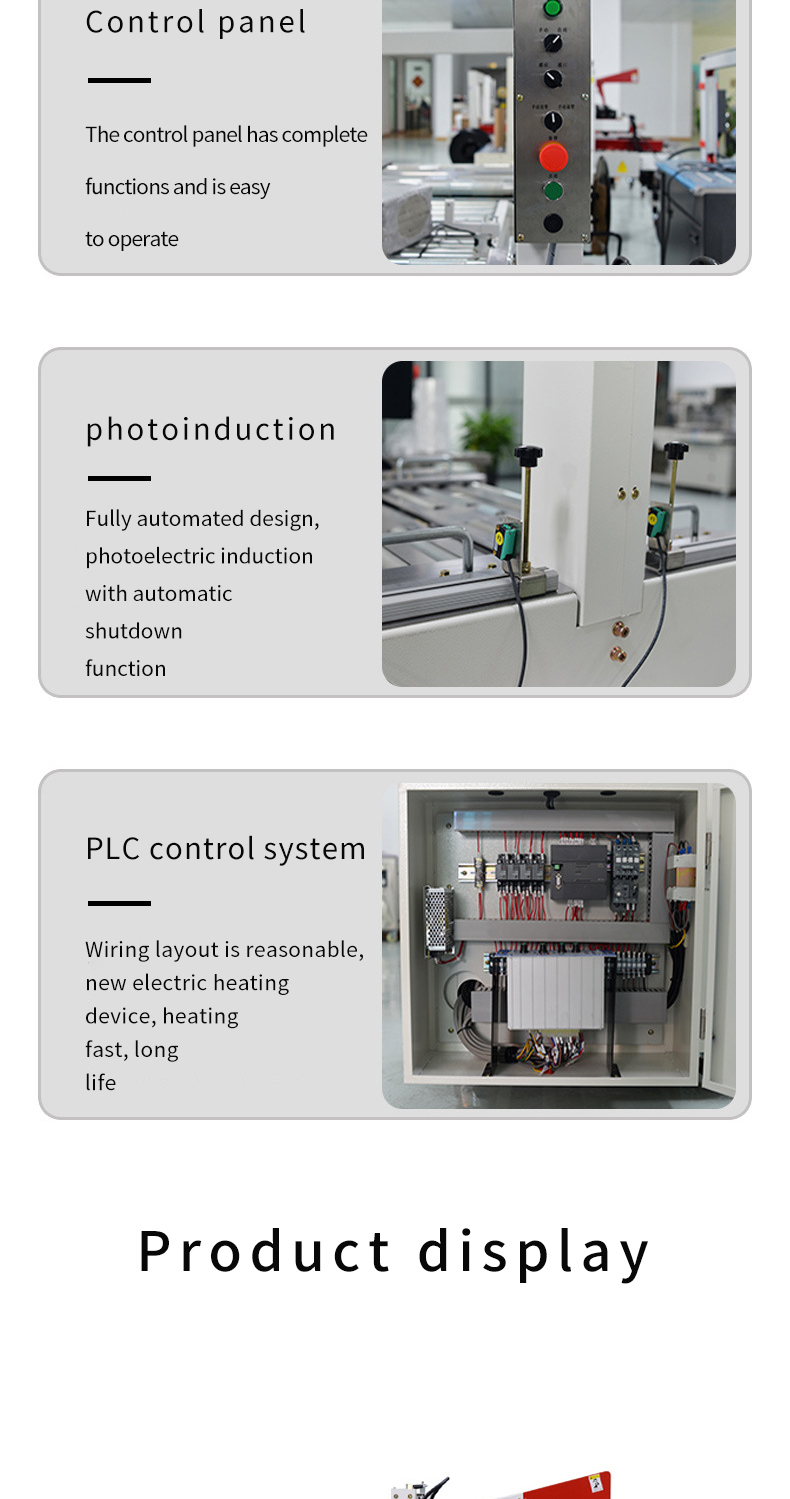

The material push device uses a pneumatic or electric push rod, and its stroke and thrust are designed according to the size and weight of the tic-tac-toe product. The heat sealing device is equipped with high-quality heating elements, such as ceramic heating plates or heating tubes, which can quickly heat up and stably maintain the set heat sealing temperature range. The heat sealing temperature can be accurately adjusted between 100-250℃.