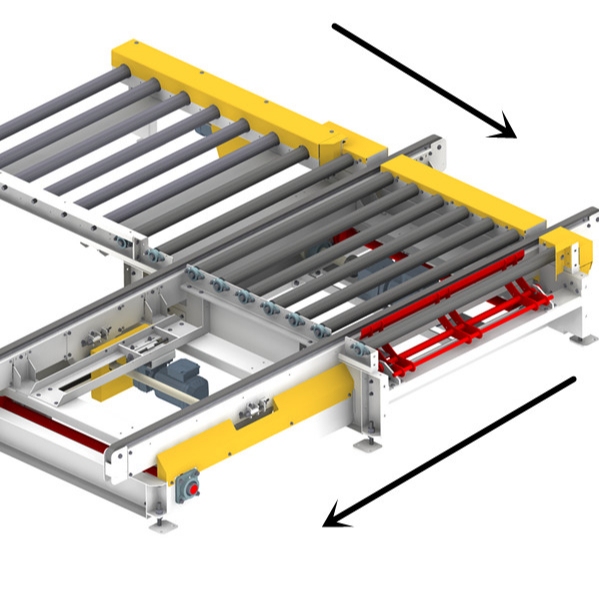

Automatic Pallet Conveyor

1. It can automatically complete the task of conveying pallets without manual handling, and can achieve 24-hour continuous operation.

2. Equipped with high-precision sensors and control systems, it can accurately control the conveying position and speed of the pallet to ensure that the pallet arrives at the designated location accurately.

3. It adopts advanced transmission technology and stable mechanical structure to keep the pallet stable during the conveying process.

4. It can be customized according to different production sites, process flows and pallet specifications.

5. It has a compact structure and small footprint, and can be flexibly laid out according to the site space.

Automatic pallet conveyors use pallets as carriers and drive the pallets through transmission components such as belts, chains, and rollers, thereby achieving continuous or intermittent transportation of goods.

Automatic pallet conveyors use pallets as carriers and drive the pallets through transmission components such as belts, chains, and rollers, thereby achieving continuous or intermittent transportation of goods.

Support structure: including frames, brackets, etc., used to support components such as conveying units, drive systems and control systems to ensure the stability and reliability of the entire conveyor. It is generally made of materials such as steel or aluminum alloy and has sufficient strength and rigidity.

Logistics and warehousing: In the warehouse warehousing, storage, sorting, and outbound processes, automatic pallet conveyors can achieve rapid handling and accurate distribution of pallet goods, improving warehouse space utilization and logistics operation efficiency.

Manufacturing field: On the production line, automatic pallet conveyors can be used for material distribution, transportation of semi-finished products and finished products, connecting different processes, realizing automation and continuity of the production process, and improving production efficiency and product quality.