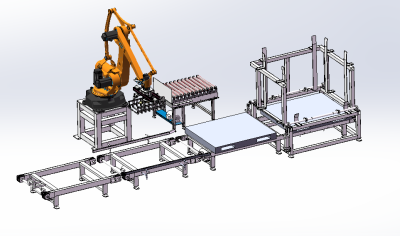

Fully automatic intelligent pallet wrapping machine

1. Automatic start and stop: It has an advanced sensing system that can automatically detect the presence of pallets and goods. When the pallet is transported to the specified position, the wrapping machine can automatically start the wrapping process without manual intervention. It can seamlessly connect with the conveying system of the production line and automatically adjust the working status according to the operating rhythm of the upstream equipment.

2. Automatic adjustment of parameters: It can automatically adjust the height, number of turns, film tension and other parameters of the wrapping according to the size of the pallet, the height and shape of the goods. For irregular-shaped goods, the machine can intelligently adjust the wrapping mode, such as increasing the number of wrapping layers or changing the wrapping angle at the protruding parts to ensure that the goods are fully protected during transportation and storage.

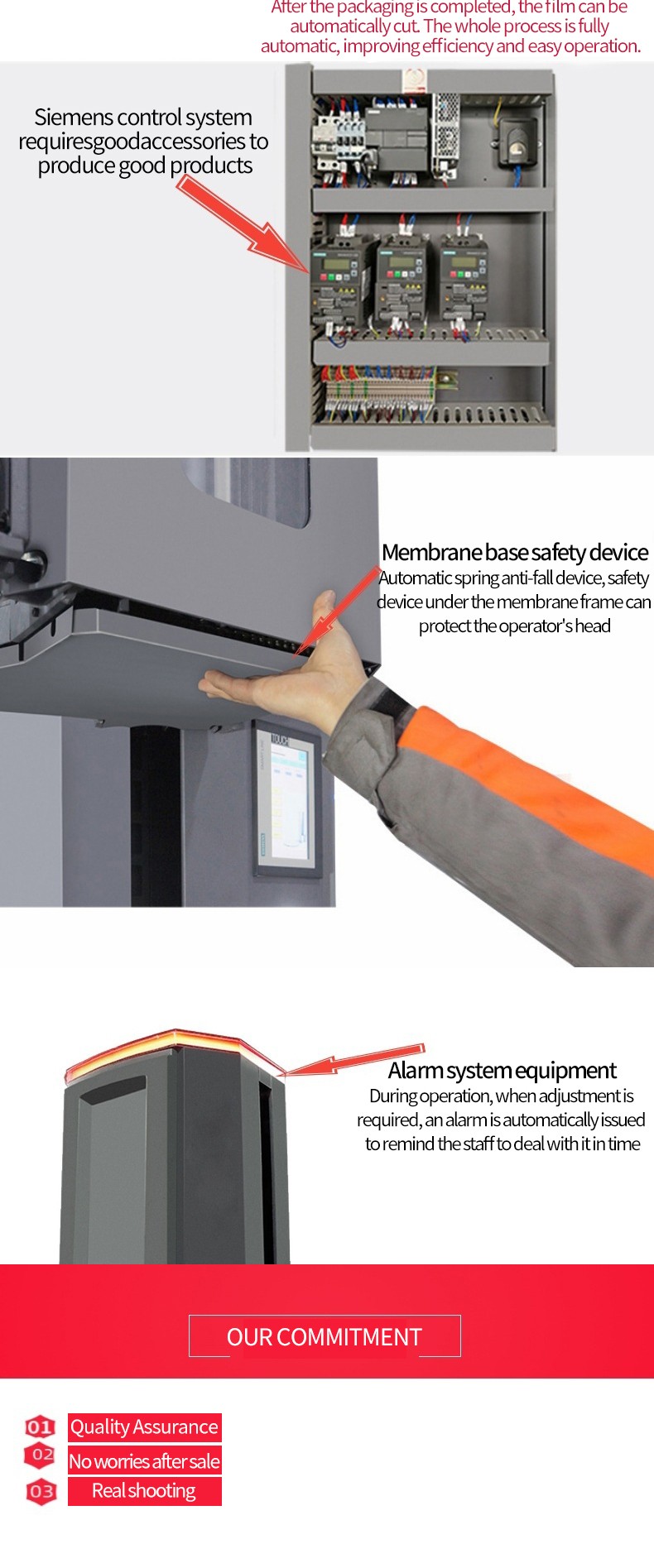

3. Intelligent fault diagnosis: The built-in intelligent diagnostic system can monitor the operating status of each component of the machine in real time. Once a fault is detected, detailed fault information will be immediately displayed on the operation interface to help maintenance personnel quickly locate and solve the problem and reduce downtime.

4. Intelligent film management: Intelligent control of film use can accurately calculate the amount of film used, and give early warning based on the remaining film amount to remind operators to replace the film roll in time. Different types and specifications of films can be selected according to different packaging needs, and the relevant winding parameters can be automatically adjusted, which improves the versatility and flexibility of the equipment.

5. Uniform and stable winding: Through precise motor control and advanced transmission system, the film can be evenly wound on the pallet and goods. During the winding process, the spacing and tension of each circle of film can be kept highly consistent to prevent the goods from being displaced and scattered during handling and transportation.

6. All-round protection of goods: Pallets and goods can be fully wrapped according to the preset program, including the bottom, side and top, to ensure that every side of the goods is fully covered and protected.

7. Fast winding speed: With a high winding speed, it can complete the winding operation of a pallet in a short time. Its efficient mechanical structure and optimized control system make the film conveying and winding actions fast and smooth, meeting the needs of large-scale production and fast packaging in logistics distribution centers.

The fully automatic intelligent pallet wrapping machine is an advanced equipment specially used for pallet cargo packaging. It perfectly integrates automation technology with intelligent functions. It aims to provide efficient and high-quality pallet wrapping packaging solutions for logistics, warehousing, production and other industries to ensure the stability and safety of goods during transportation and storage.

The stretch film is used as the packaging material and applied to pallet packaging. Various regular or irregular commodities are packaged by wrapping. The shrinkage and self-adhesiveness of the stretch film are used to bind the goods and pallets into a whole, which plays a role of fixing. Therefore, the goods will not be scattered or collapsed. It can also prevent dust, moisture and damage to the goods. It is particularly suitable for mass transportation or storage, bundling cartons, bottled goods or large goods. At the same time, it reduces labor intensity and improves work efficiency. It is an ideal equipment for modern enterprise product packaging.

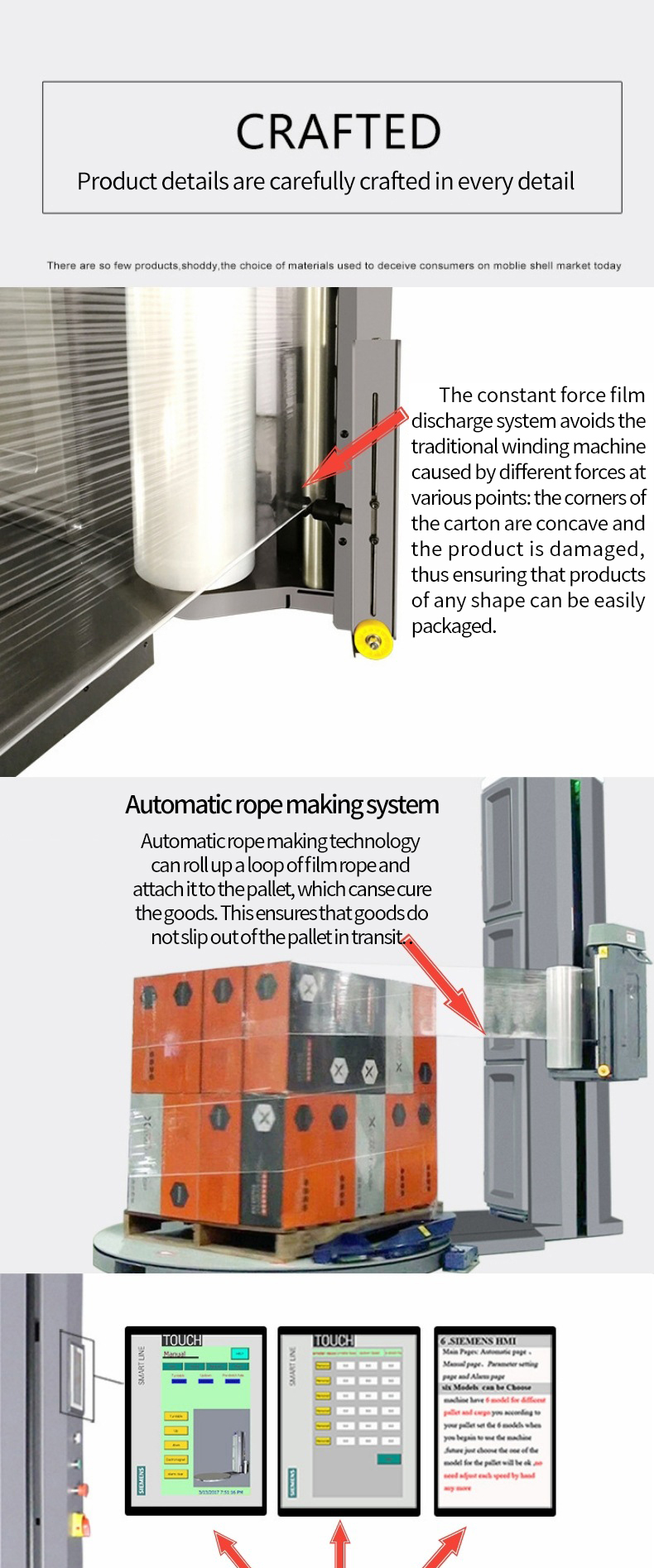

The constant force film release system avoids the phenomenon of concave corners of cartons and damage to products caused by different forces at different points in traditional wrapping machines, thus ensuring that products of any shape can be easily packaged.

Automatic rope making system, automatic rope making technology can roll the film rope into a circle and fix it on the pallet to solidify the goods. This ensures that the goods will not slip out of the pallet during transportation.

The LCD touch operating system is intuitive and easy to understand. The one-button remote control system is easy to operate. It is more convenient to start and pause the machine through the remote control. One remote control can only control one device.

Optional automatic film loading and film cutting functions. The pressurizing device adopts an electric pressurizing system to prevent the goods from scattering and shifting during the winding process. The pressurizing stroke is 500mm-2000mm, which is twice as wide as the traditional pneumatic pressurization and has a wider range of applications.

Intelligent fault detection and early warning: Built-in complex and precise fault diagnosis module, real-time monitoring of the machine's various subsystems and key components, such as motors, transmission mechanisms, sensors, film conveying systems, etc. Once an abnormal situation is detected, such as motor overload, sensor signal abnormality, film jam or breakage, etc., detailed fault codes and prompt information can be quickly displayed on the operation interface.