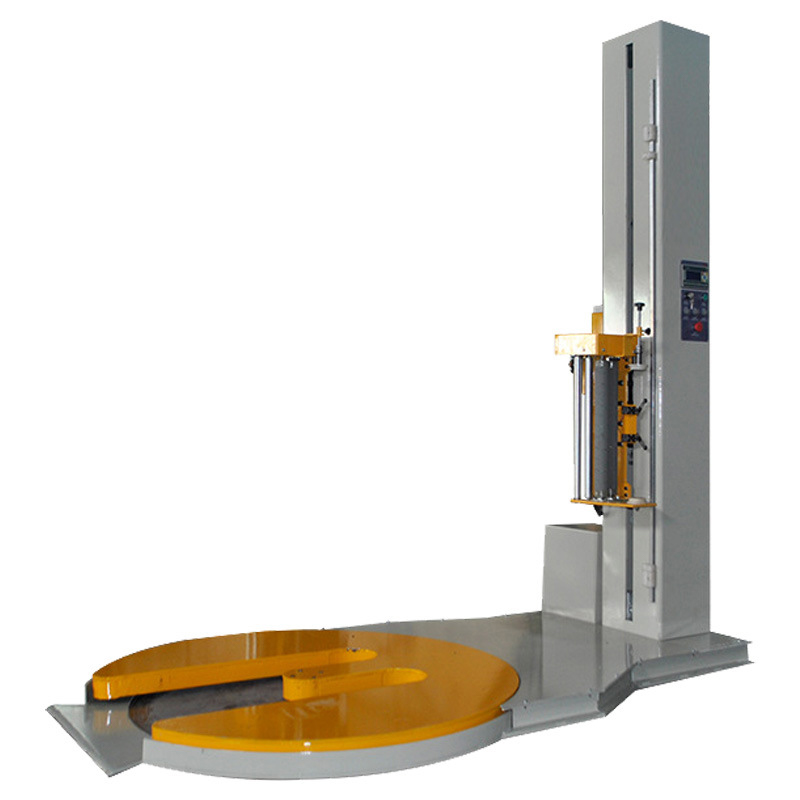

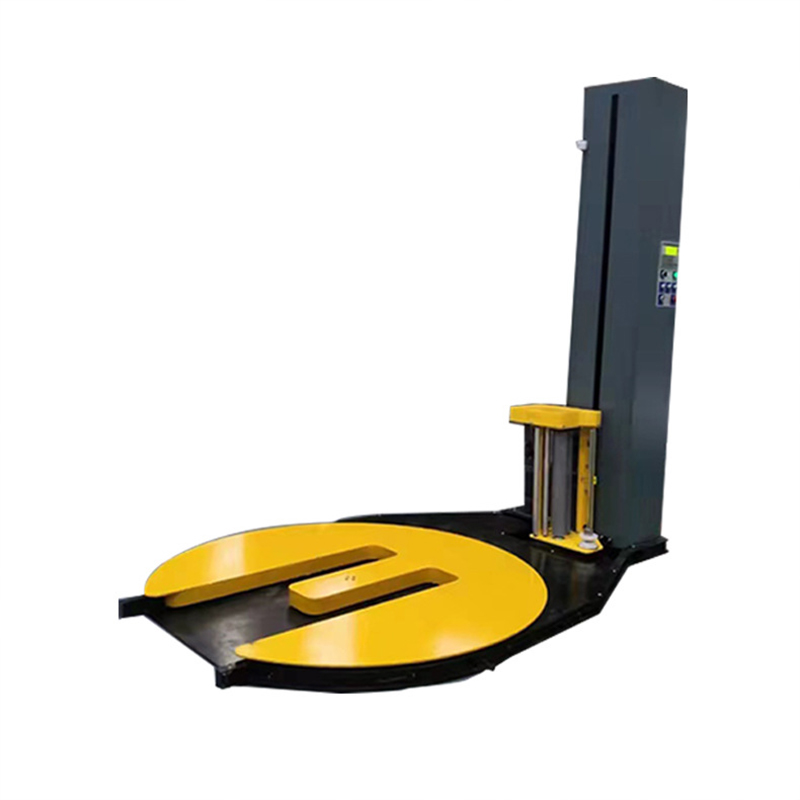

M type pallet wrapping machine

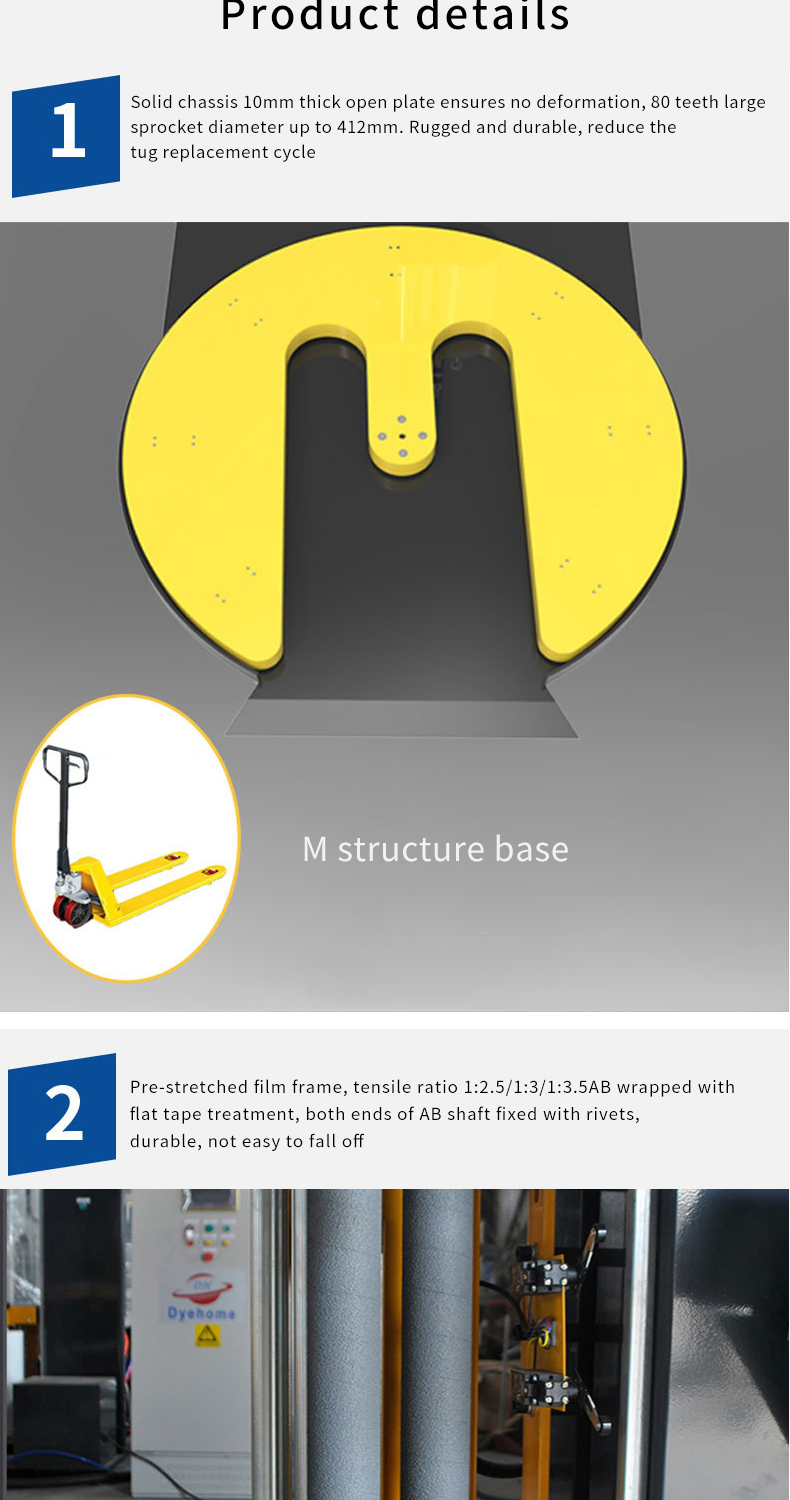

1. The M-type chassis is designed with a special forklift hole for manual loading and unloading, which does not require customers to make a separate foundation or equip a ramp.

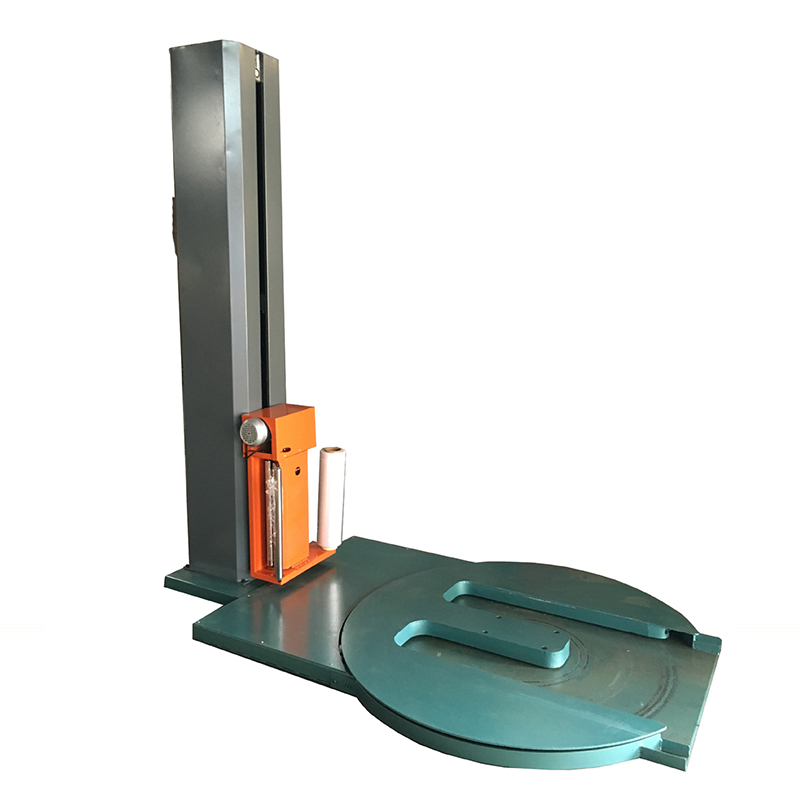

2. It is generally driven by friction wheels, which can meet daily packaging needs, and the overall structure of the equipment is relatively simple.

3. It is equipped with a PLC programmable control system, the operation interface is intuitive and friendly, and parameters can be easily set through the human-machine interface.

4. It is equipped with a photoelectric switch that can automatically sense the height of the goods and automatically adjust the winding height according to the height of the goods to ensure the winding effect.

5. The film rack adopts an AC motor pre-stretching mechanism, which can make the film wrap the goods more tightly, improving the stability and aesthetics of the packaging.

The M-type pallet wrapping machine is an advanced equipment designed specifically for pallet cargo packaging, playing a key role in the logistics and warehousing links of many industries.

The M-type chassis design is used, and the forklift holes for manual loading and unloading are ingeniously set. This greatly facilitates the loading and unloading operations of the equipment, can be easily put into place, and effectively saves valuable site space.

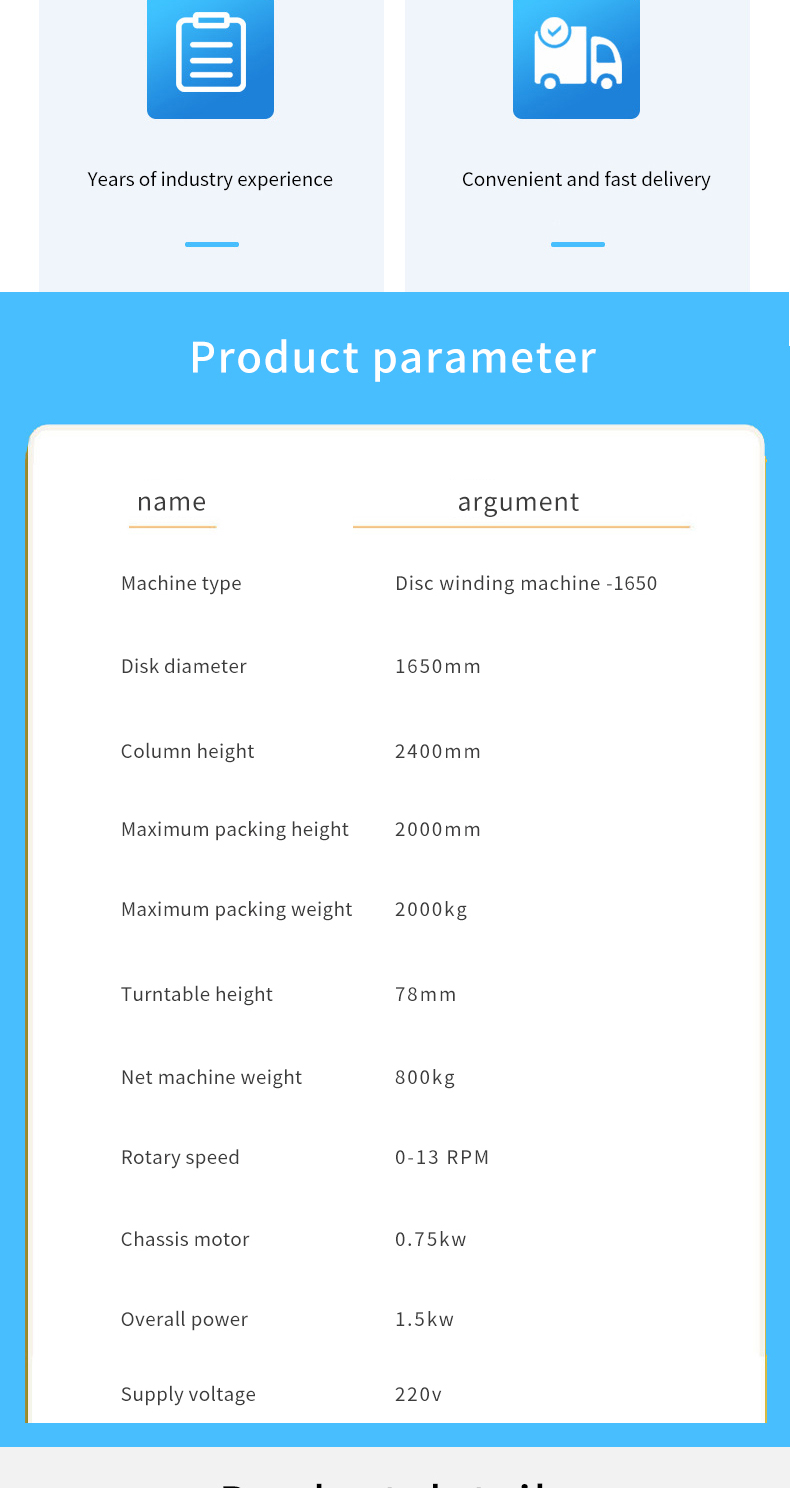

Machine type:Disc winding machine -1650

Disk diameter:1650mm

Column height:2400mm

Maximum packing height:2000mm

Maximum packing weight:2000kg

Turntable height:78mm

Net machine weight:800kg

Rotary speed:0-13 RPM

Chassis motor:0.75kw

Overall power:1.5kw

Supply voltage:220v

A friction wheel drive mechanism is usually used. This drive method meets certain load requirements while maintaining the relative simplicity of the equipment structure.

Its film frame is equipped with an advanced AC motor pre-stretching mechanism. In this way, while using the same amount of film, the film can be more closely and firmly attached to the surface of the pallet, which significantly enhances the stability and protective performance of the packaging.

The M-type pallet wrapping machine has a wide variety of wrapping methods to choose from. Operators can flexibly control the number of wrapping turns at the top and bottom and accurately set the number of reciprocating wrapping times according to the shape, size, weight, transportation and storage requirements of different goods.

The M-type pallet wrapping machine has a built-in advanced fault detection system that can monitor the key parameters and operating status of the equipment in real time during operation.