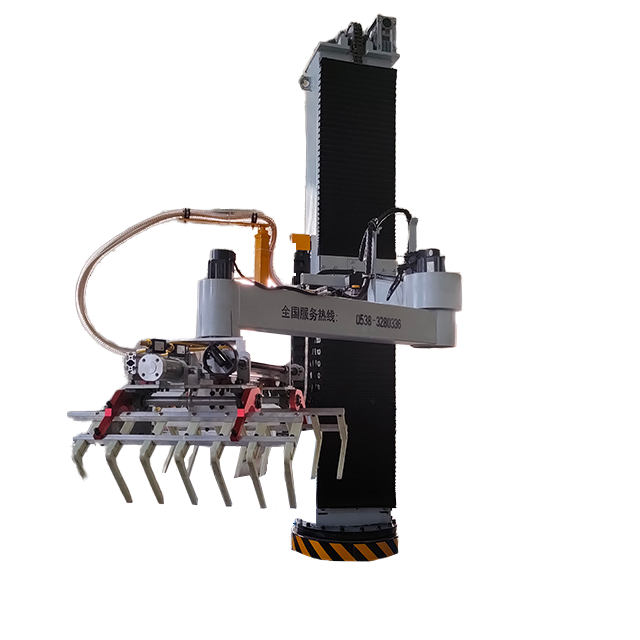

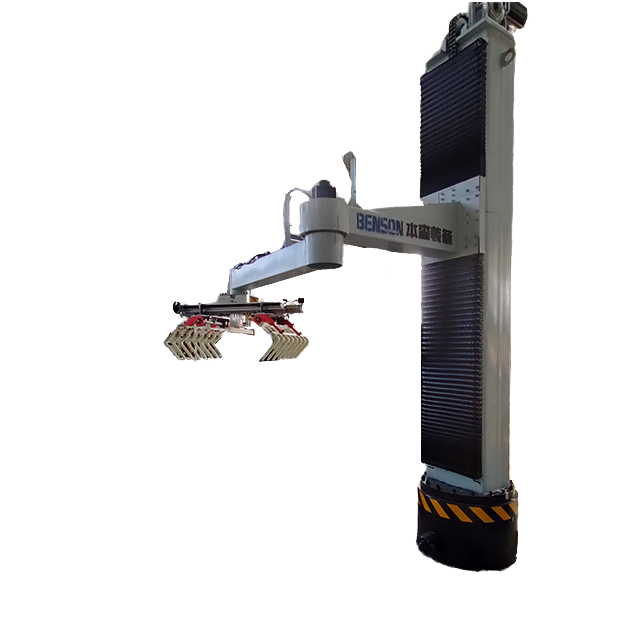

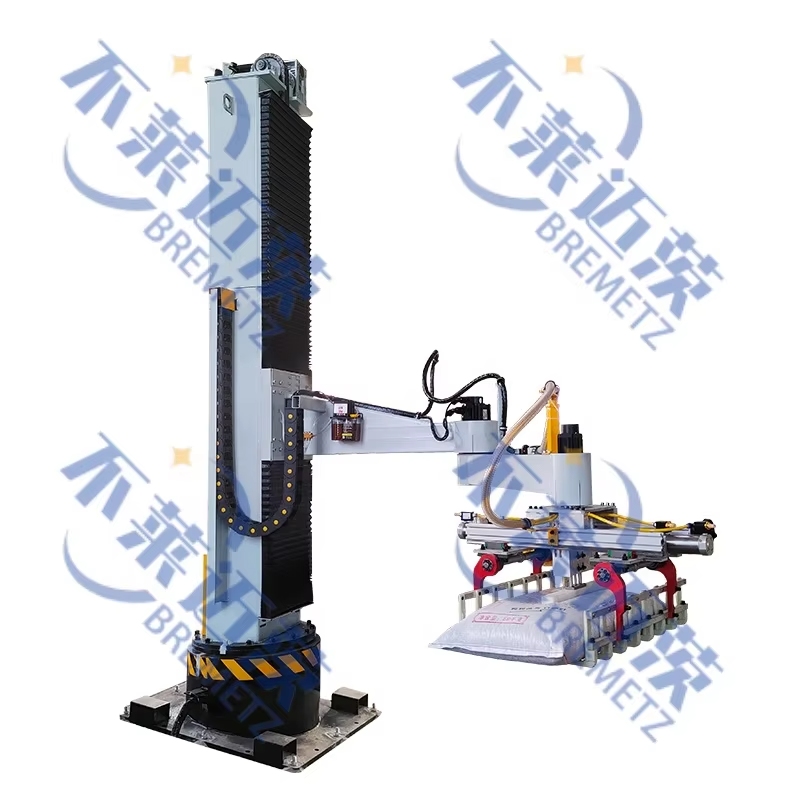

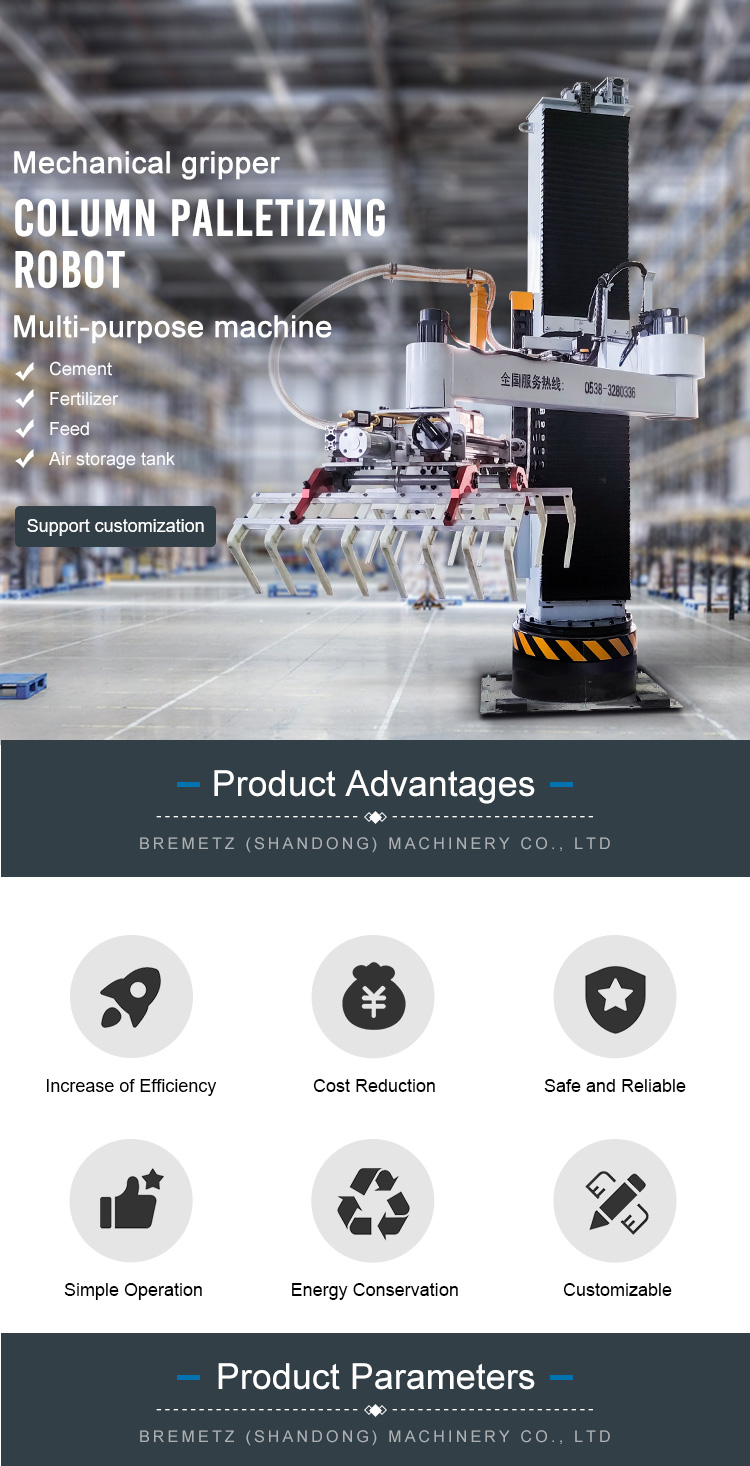

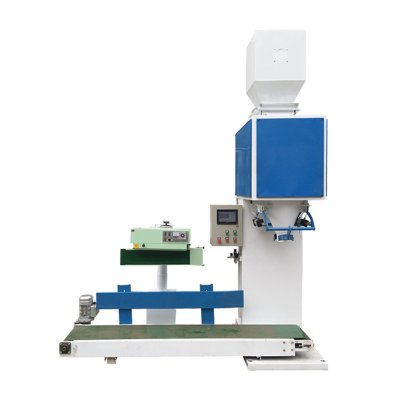

Column type palletizing robot

1. Small footprint: The column-type structure is compactly designed. Compared with other types of palletizing equipment, it occupies less space in the factory, especially suitable for workshops or factories of small and medium-sized enterprises with limited space.

2. Large working range: Its vertical column and flexibly movable mechanical arm can cover a large working area, and can palletize goods in different positions, which increases the flexibility and applicability of the equipment.

3. Smooth operation: The column structure provides stable support for the robot, and the robot moves more smoothly during the palletizing process.

4. Accurate positioning: Equipped with advanced control systems and sensors, it can accurately locate the position and posture of the goods. Whether it is bags, boxes or barrels, etc., the goods of different shapes and packaging can be accurately grasped and placed in the designated position to ensure the accuracy and quality of palletizing.

5. Fast grasping: The mechanical arm moves quickly and efficiently, and can complete the grasping and palletizing operations of goods in a short time, greatly improving the efficiency of palletizing.

6. Multi-purpose: It can adapt to the palletizing of various types of goods, including bags, boxes, barrels, bottles, plates, blocks and other materials of different shapes and packaging.

7. Multi-line sharing: It can be used in multiple production lines at the same time, which improves the utilization rate of equipment. When goods from different production lines need to be palletized, the column-type palletizing robot can quickly switch working modes to meet the diversified production needs of enterprises.

Column type palletizing robot is an advanced automatic palletizing equipment. Its unique column structure makes it stand out among many palletizing solutions. It combines high-precision mechanical design, intelligent control system and flexible operation functions, and can efficiently and accurately complete the palletizing tasks of various types of goods. It is widely used in logistics, warehousing, food and beverage, chemical industry, building materials and many other industries.

Palletizer name and model:BENS120-2400

Movement degrees of freedom (axis):4

Maximum load capacity (kg):120

Repeat positioning accuracy (mm):±0.3mm

Drive mode:Servo drive

Vehicle:Fixture

Palletizing memory:Intelligent memory

Maximum coverage:2350

Body weight:1025

Installation method:Ground

CHOOSE MATERIALS CAREFULLY,Strictly select good metal materials the structure is firm and stable, and the use time is long.

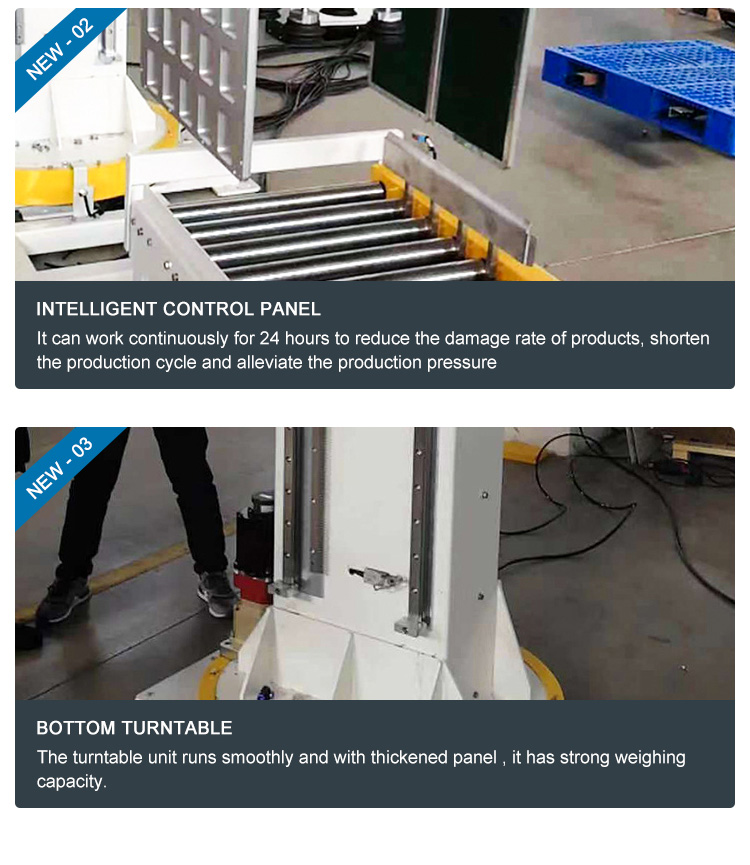

INTELLIGENT CONTROL PANEL,It can work continuously for 24 hours to reduce the damage rate of products, shorten the production cycle and alleviate the production pressure.

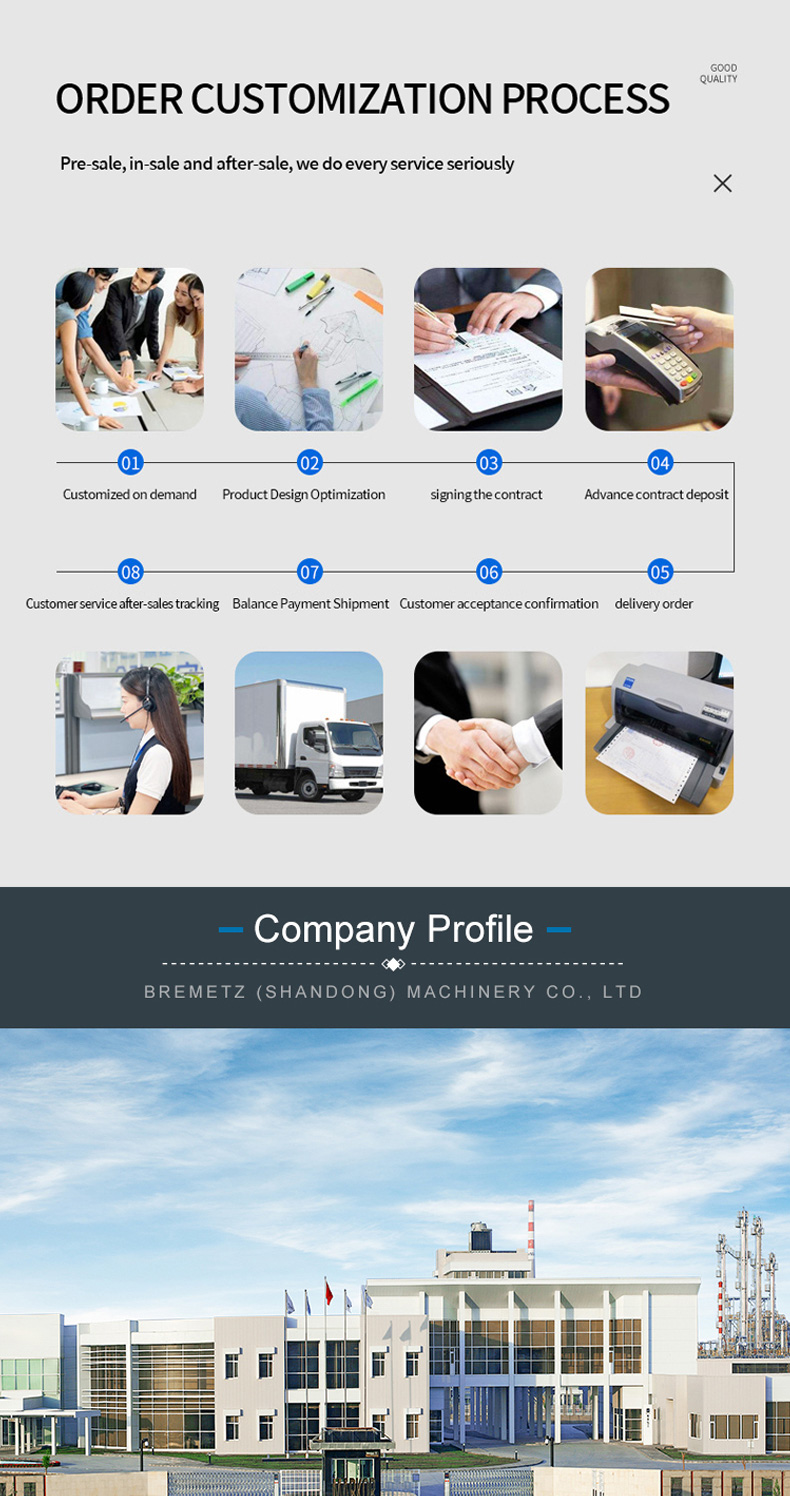

BOTTOM TURNTABLE,The turntable unit runs smoothly and with thickened panel, it has strong weighing capacity.

Product Application:

Logistics and warehousing industry, in logistics centers and warehouses, column type palletizing robot is used to grab goods from conveyor belts and palletize them on pallets, or disassemble goods on pallets to improve the loading and unloading efficiency and storage density of goods.

Food and beverage industry, used for packaging and palletizing of food and beverages, such as palletizing boxes of beverages, bags of food, etc. on pallets. Its sanitary design meets the requirements of the food industry and can ensure the safety and hygiene of food.

Chemical industry, in the production and packaging process of chemical products, chemical raw materials such as barrels and bags are palletized.

Building materials industry, for the palletizing of building materials such as bagged cement, tiles, and panels, robots can perform efficient palletizing according to different product characteristics and packaging forms.

We provide a professional installation team to install the Column type palletizing robot at the location specified by the user and conduct comprehensive debugging to ensure the normal operation of the equipment. At the same time, we provide users with operation training services, including equipment operation methods, programming skills, daily maintenance knowledge, etc., so that operators can master the use of the equipment proficiently.

We have a professional after-sales maintenance team and have established a complete after-sales service network across the country. When the equipment fails, users can contact our after-sales service center in time, and the maintenance personnel will respond and arrive at the site for maintenance in the shortest time. We also have sufficient original accessories to ensure the timeliness and quality of maintenance.

We continue to pay attention to the development of the industry and the progress of technology, and regularly provide users with technical upgrade services for equipment. Through software updates, hardware improvements, etc., we continuously improve the performance and functions of equipment, so that users' investments can maintain their value in the long term and create more value for users.