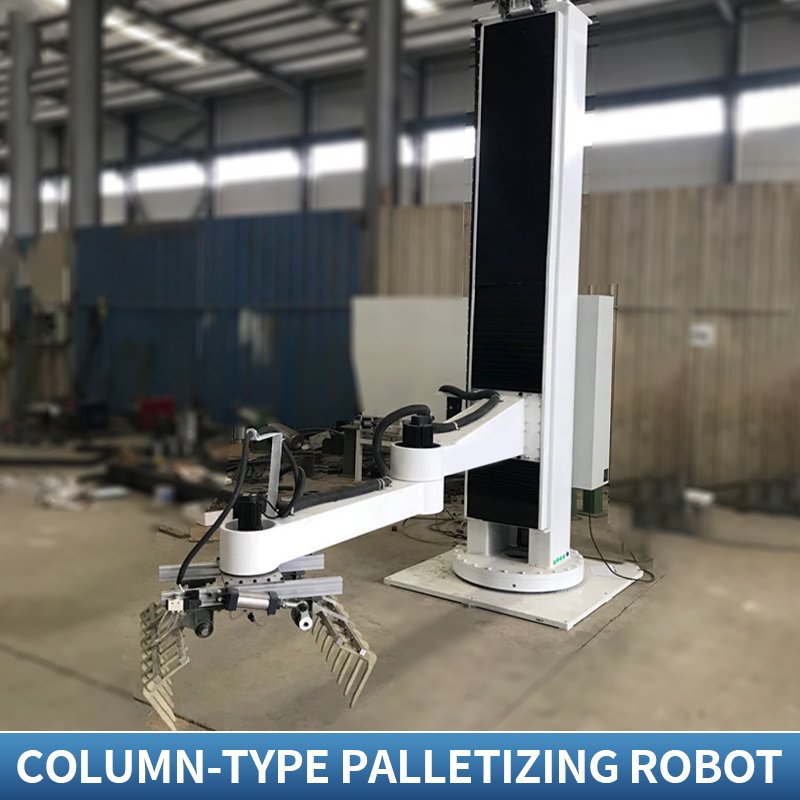

Corrugated paper palletizing column robot

1, simple structure, fewer parts. Therefore, the failure rate of parts is low, the performance is reliable, the maintenance is simple,

2. Small footprint. It is conducive to the layout of the production line in the customer's factory, and can leave a larger warehouse area. Palletizing robots can be set up in narrow Spaces and can be used effectively.

3, strong applicability. When the size, volume, shape and pallet size of the customer's products change, it only needs to be slightly modified on the touch screen, which will not affect the normal production of the customer. The mechanical palletizer change is quite troublesome and even impossible to achieve.

4, low energy consumption. Usually the power of the mechanical palletizer is about 26KW, and the power of the palletizing robot is about 5KW. Greatly reduce the customer's operating costs.

5, all controls can be operated on the screen of the control cabinet, the operation is very simple.

6. Just locate the starting point and place the point, and the teaching method is simple and easy to understand.

Corrugated paper palletizing column robot,a layer of work that meets the requirements of the pallet, and the plate and the work are moved forward until the pallet is perpendicular. The upper baffle rod drops, the other three positioning baffle rod starts clamping, and the plate is reset at this time. Each workpiece is lowered to the pallet plane, the pallet plane is 10mm away from the bottom surface of the plate, and the pallet is lowered by one workpiece height. Repeat until pallet stacking meets set requirements. The palletizing robot is equipped with a specially designed multi-function grabber, which allows the robot to grip and transfer packages securely using vacuum suckers, regardless of box size or weight。

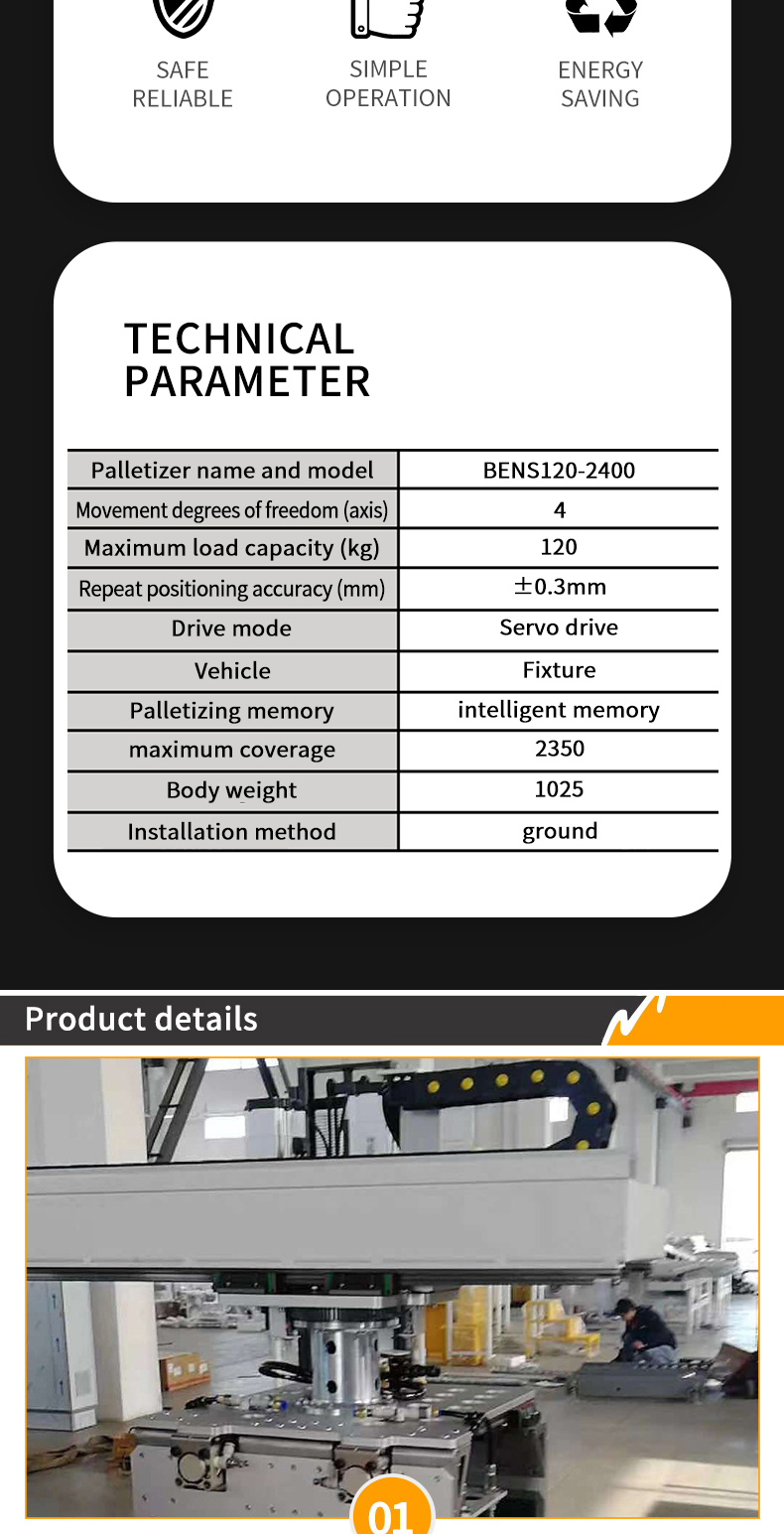

Technical parameters: Palletizer name and model: BENS120-2400; Freedom of motion (axis) : 4; Maximum load (kg) :120; Repeated positioning accuracy (mm) : ± 0.3mm; Drive mode: servo drive; Vehicles: fixtures; Palletizing memory: intelligent memory; Maximum coverage: 2350; Weight: 1025; Installation method: ground.

Column part: Material: The column is the main supporting structure of the robot. It is generally made of high-strength carbon steel or stainless steel to ensure that it can withstand various loads and stresses during the robot's work, and is not easily deformed or damaged during long-term use.