Intelligent High-Efficiency Palletizing Robot

1. Advanced control system: It adopts advanced intelligent control system with powerful data processing capability and computing speed. It can monitor the operation status of the robot in real time, accurately control the execution of each action, and ensure the accuracy and stability of the palletizing process.

2. Intelligent identification and perception: It is equipped with high-precision sensors, such as visual sensors, laser sensors, etc., which can accurately identify and locate the goods. It can automatically adjust the action or issue an alarm in time to ensure the safety and reliability of the work.

3. High-speed palletizing capability: It has high-speed motion mechanism and actuators, which can quickly complete the grabbing, handling and stacking of goods. The design fully considers the coordination and fluency of the movement. By optimizing the mechanical structure and motion trajectory, unnecessary pauses and waiting time are reduced, and the palletizing speed is further improved.

4. Continuous and stable operation: The use of high-quality components and reliable manufacturing processes ensures the stability and reliability of the robot during long-term work. It can adapt to high-intensity, continuous and uninterrupted palletizing tasks, reduce downtime caused by equipment failure or maintenance, and improve production efficiency and equipment utilization.

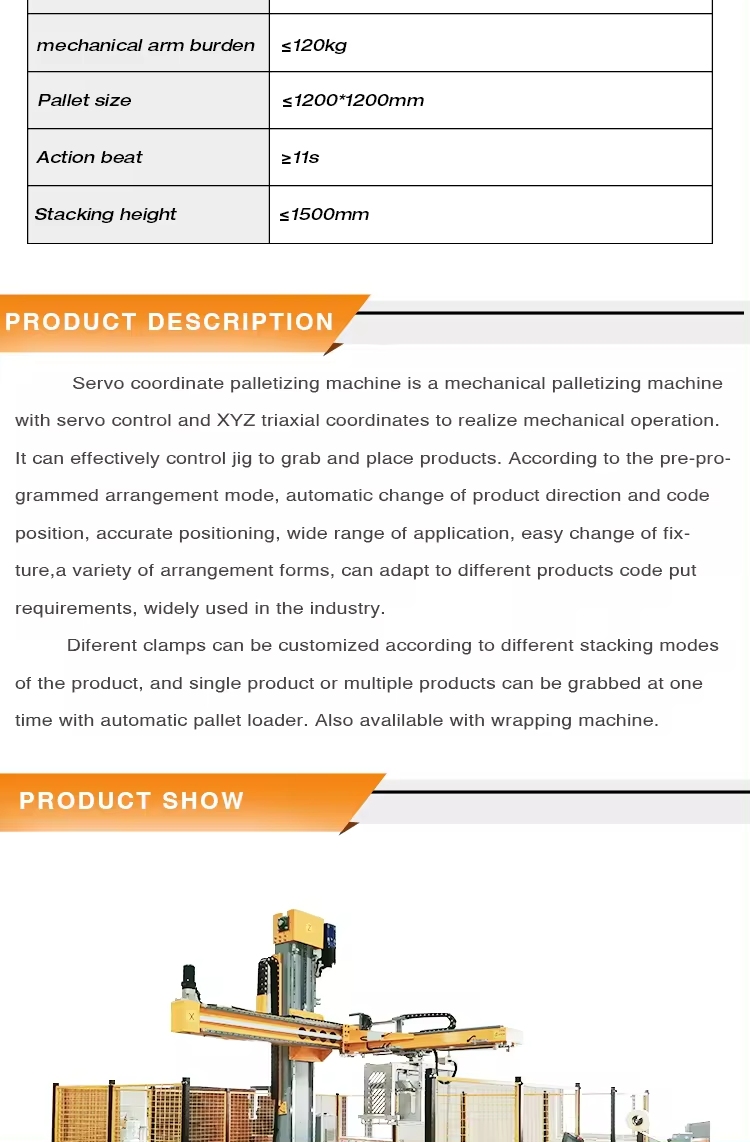

The intelligent and efficient pallet stacking robot is an automated equipment that integrates advanced technology and excellent performance, and is designed to provide efficient, accurate and reliable pallet stacking solutions for the logistics and production links of various industries. It adopts an intelligent control system, combined with a high-precision mechanical structure and advanced sensor technology, and can achieve fast and accurate palletizing of various goods, greatly improving production efficiency and logistics operation efficiency, and reducing labor costs and labor intensity.

Model:SMD12,Power supply:3Phase, AC220V/380V,50/60HZ, 7KW,Air pressure:450NL/min,Machine Size:L4500*W4300*H3500mm,mechanical arm burden:≤120kg,Pallet size:≤1200*1200mm,Action beat:≥11s,Stacking height:≤1500mm

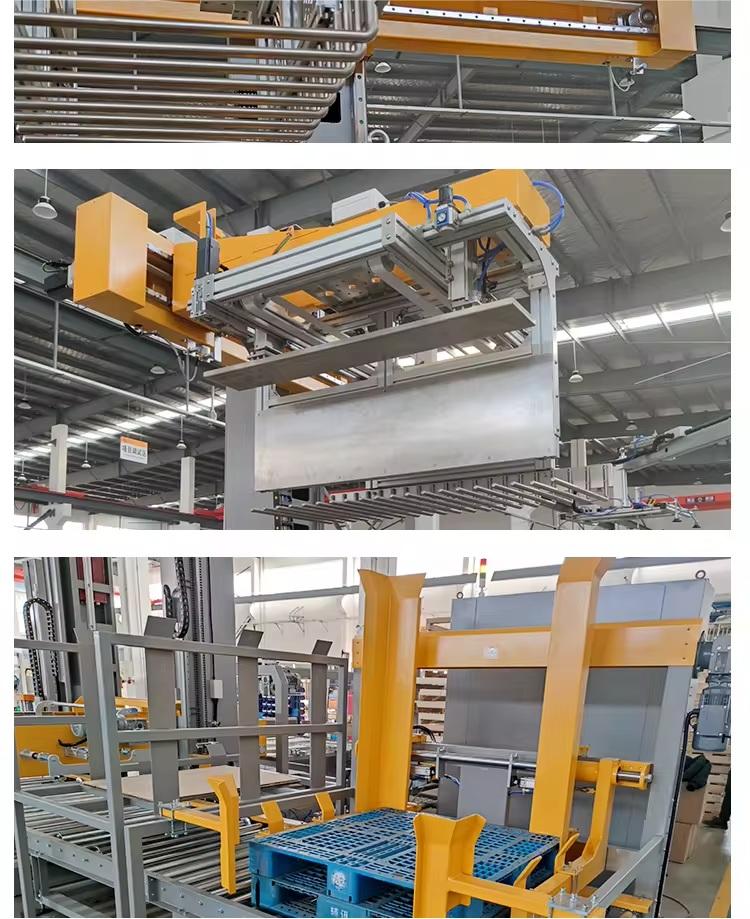

It integrates a variety of high-precision sensors to achieve all-round perception of goods and working environment. The visual sensor can quickly identify the shape, position and posture of the goods, and provide accurate coordinate information for the robot's grasping and stacking; the laser sensor is used to measure the distance and position relationship between the goods and the robot to ensure the accuracy of grasping and placement; the force sensor monitors the force of the grasping device in real time to prevent damage or falling of the goods due to excessive or insufficient grasping force.

Equipped with professionally designed grasping devices, it can be customized according to the shape, size and weight of the goods. Common grasping devices include claw type, suction cup type, etc., which can realize reliable grasping and placement of various goods, ensuring the safety and stability of goods during stacking.

The design fully considers the needs of different industries and application scenarios, and has strong flexibility and adaptability. It can adapt to the palletizing of goods of various shapes, sizes and weights, including common types of goods such as cartons, bags, barrels, bottles, and various irregular shapes.

For pallets of different specifications, such as standard pallets, customized pallets, etc., they can be easily adapted. The palletizing layout and number of layers can be automatically adjusted according to the size and shape of the pallet to achieve the best space utilization and palletizing effect. In addition, the robot also supports seamless docking with other automation equipment and production lines, and can be flexibly adjusted and integrated according to changes in the production process to meet diverse production needs.