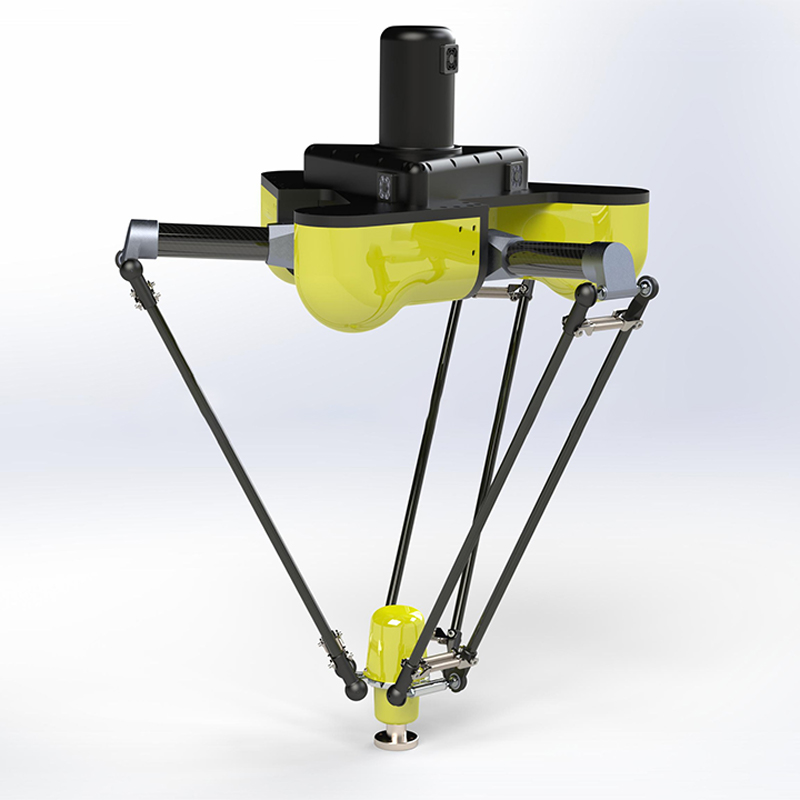

Industrial four-axis parallel robot

Handling robot is a high-tech in the field of modern automatic control, involving mechanics, mechanics, electrical hydraulic pressure technology, automatic control technology, sensor technology, single-chip microcomputer technology and computer technology and other disciplines, has become an important part of modern machinery manufacturing production system. Its advantage is that it can complete various expected tasks through programming, and it has the respective advantages of humans and machines in its own structure and performance, especially reflecting artificial intelligence and adaptability.

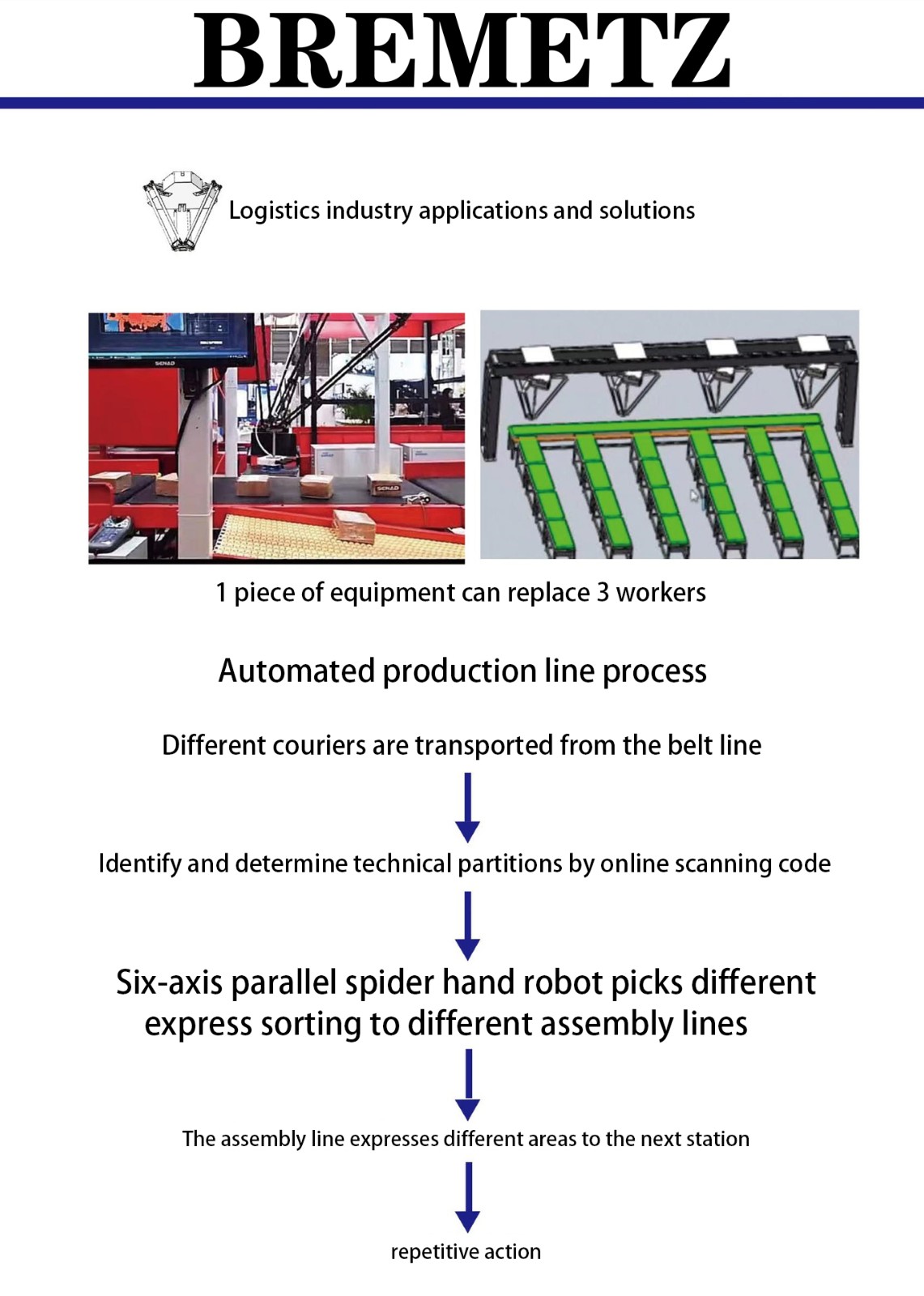

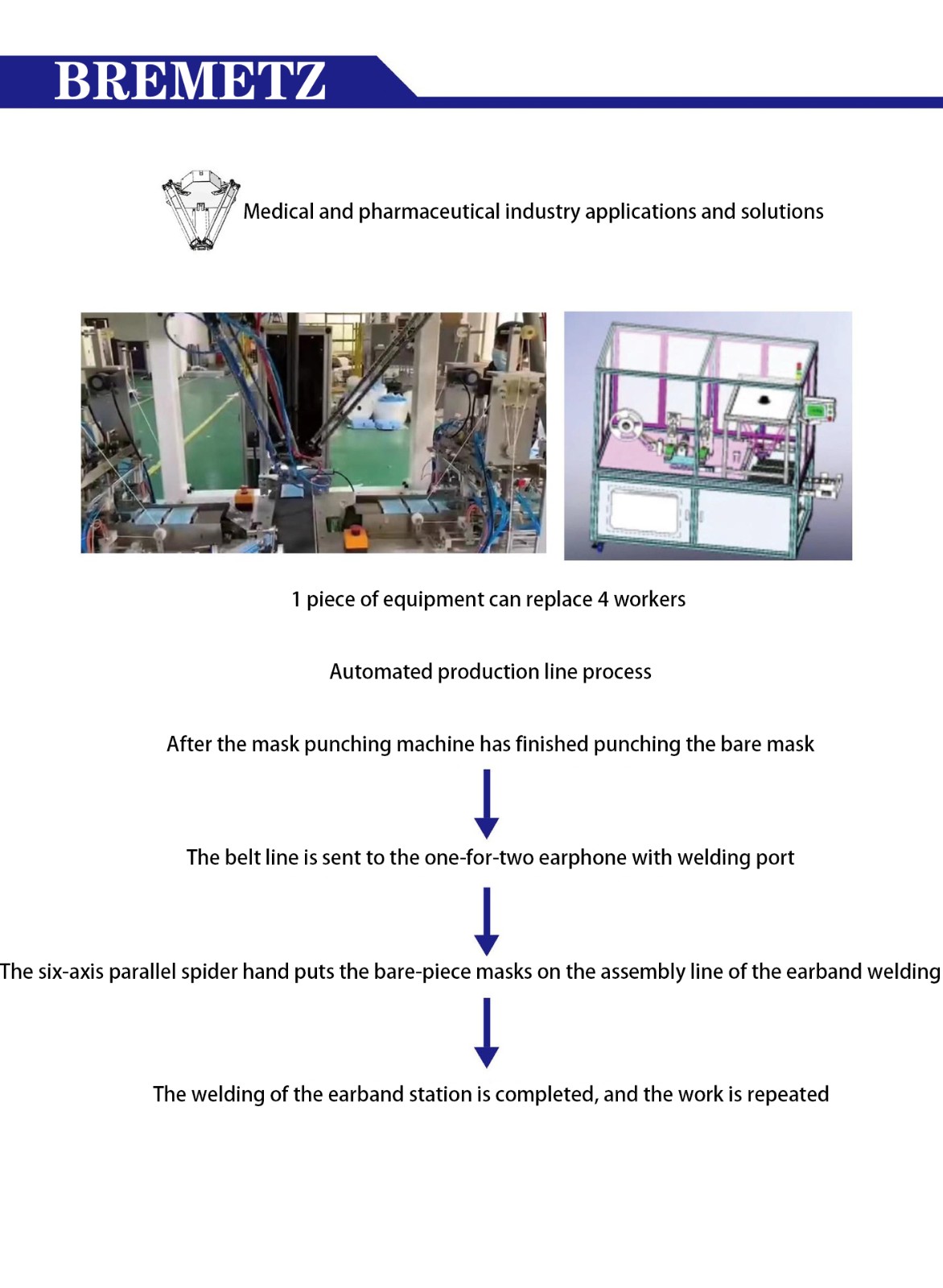

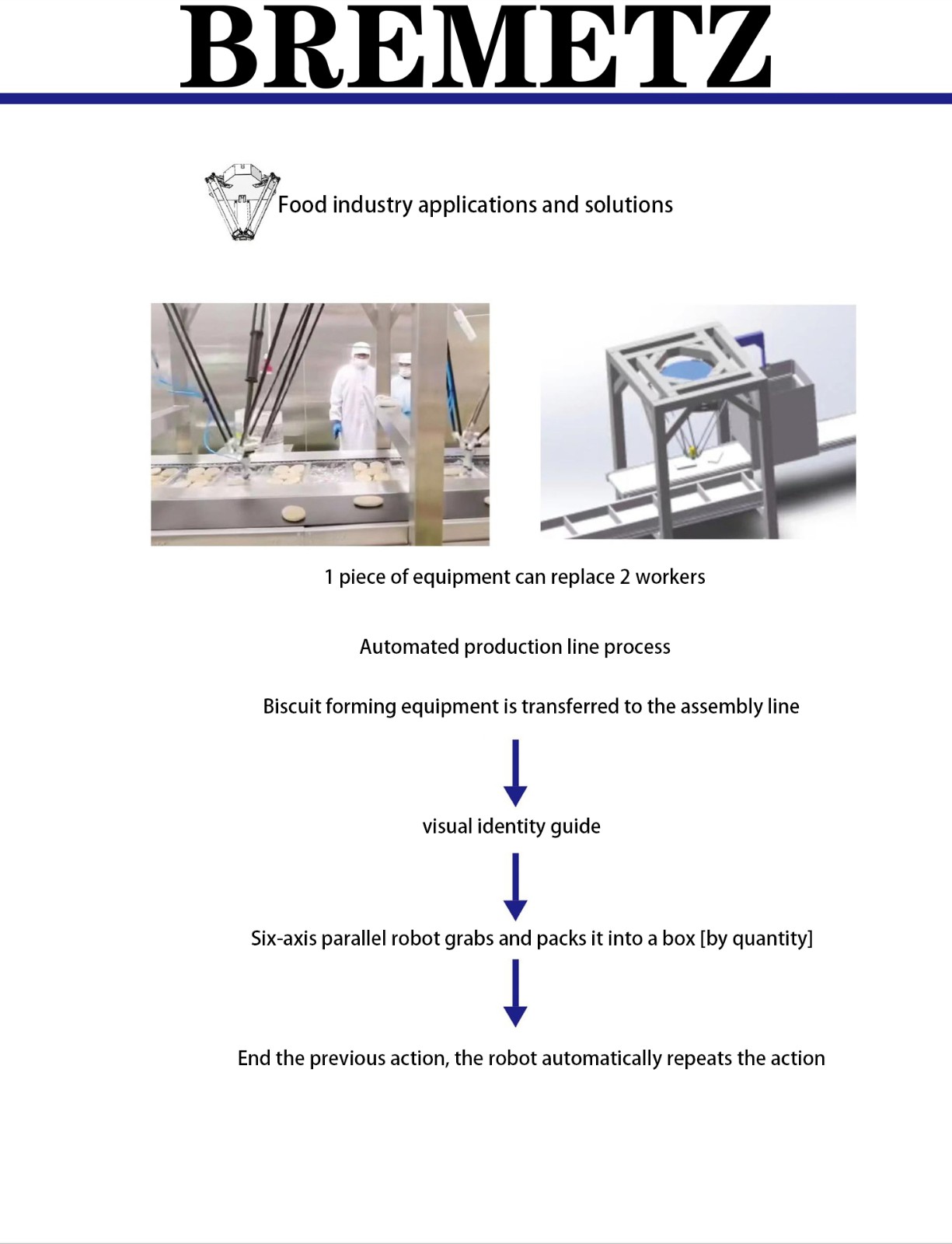

transfer robot is an industrial robot that can carry out automated handling operations. The first handling robots appeared in the United States in 1960, when Versatran and Unimate were first used in handling operations. Handling operation refers to holding the workpiece with a piece of equipment, which refers to moving from one processing position to another processing position. The handling robot can install different end-effectors to complete the handling of various workpieces of different shapes and states, which greatly reduces the heavy manual labor of human beings. There are more than 100,000 handling robots used in the world, which are widely used in the automatic handling of machine tools, automatic production lines of punching machines, automatic assembly lines, palletizing, containers, etc. Some developed countries have formulated the maximum limit of manual handling, which must be completed by handling robots.