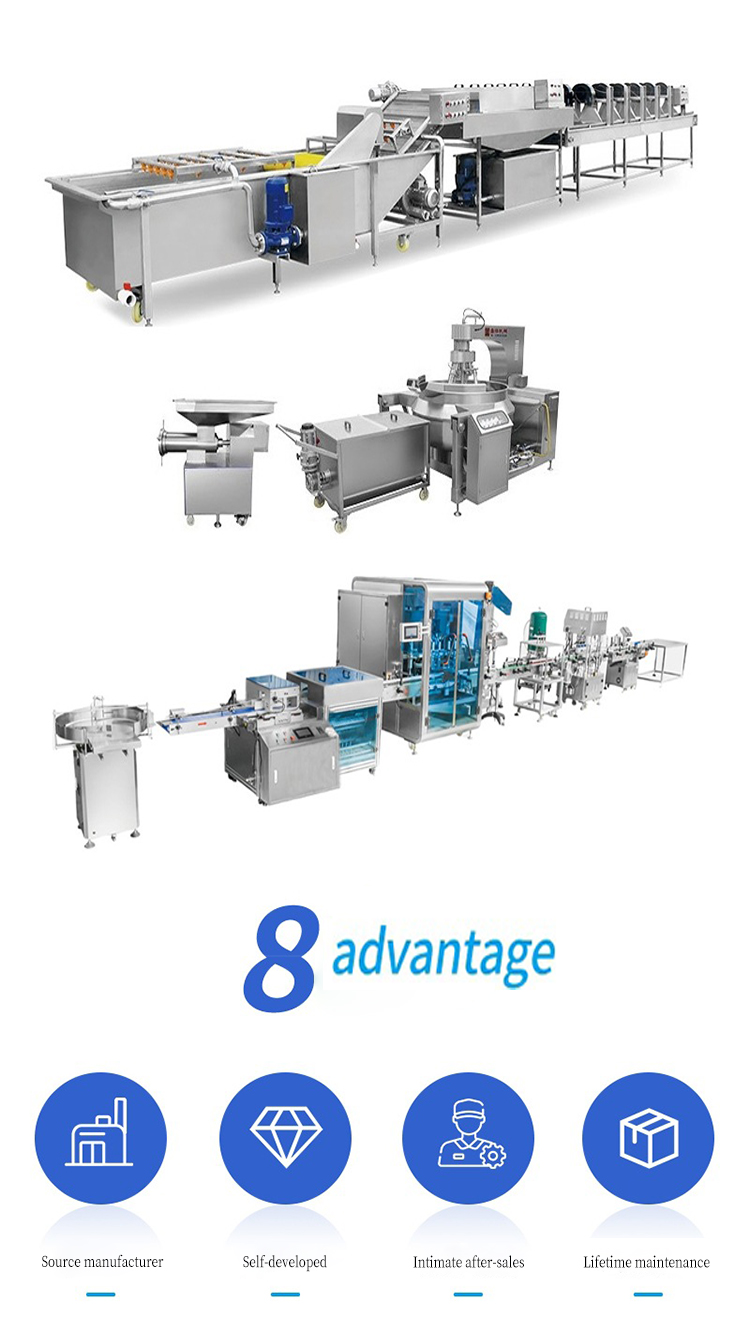

Automatic paste filling line

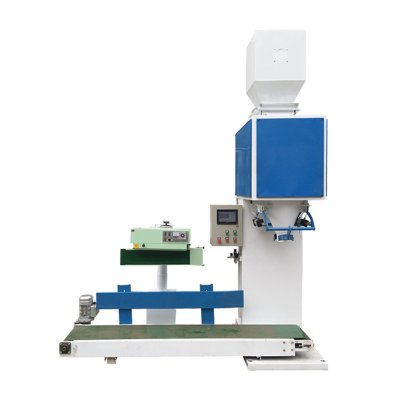

The paste filling line is designed for materials with high viscosity, such as food sauces, cosmetics, ointments, lubricants, etc. Combining automation technology, mechanical engineering and fluid management, this line offers a number of significant advantages: an automated paste filling line can significantly increase production efficiency. It can fill a large number of products in a short time, reducing the time required for manual operation, thereby speeding up production. Modern paste filling equipment uses a sophisticated metering system to ensure that the filling amount of each product is accurate. This not only helps to maintain the consistency of product quality, but also avoids the waste of raw materials. The paste filling line can be flexibly adjusted to adapt to different viscosity and characteristics of the material. Automated operations reduce manual participation, reduce labor intensity, and reduce labor costs. In addition, the reduction of manual operations also helps to improve the safety of the production process. The paste filling line can be operated in a closed environment, reducing pollution and external interference during the filling process, thereby improving the sanitary quality and shelf life of the product. Modern paste filling machine equipment design is humanized, the operation interface is intuitive and easy to understand, and employees can get started with simple training. With the growth of production needs of enterprises, the paste filling line can be expanded by increasing the filling head, expanding the length of the production line or adding other functional modules to meet the larger production needs.

The paste filling line is an efficient, automated portfolio of equipment designed to provide high-precision, high-efficiency filling solutions for products with high viscosity. This production line is widely used in food, cosmetics, medicine, chemical and other industries, especially for paste, paste, cream, shampoo, lubricating oil and other paste or viscous liquid packaging treatment.