Fully automatic paste filling machine

1. It can run continuously for a long time, with fast filling speed, which can greatly improve production efficiency and meet the needs of large-scale production.

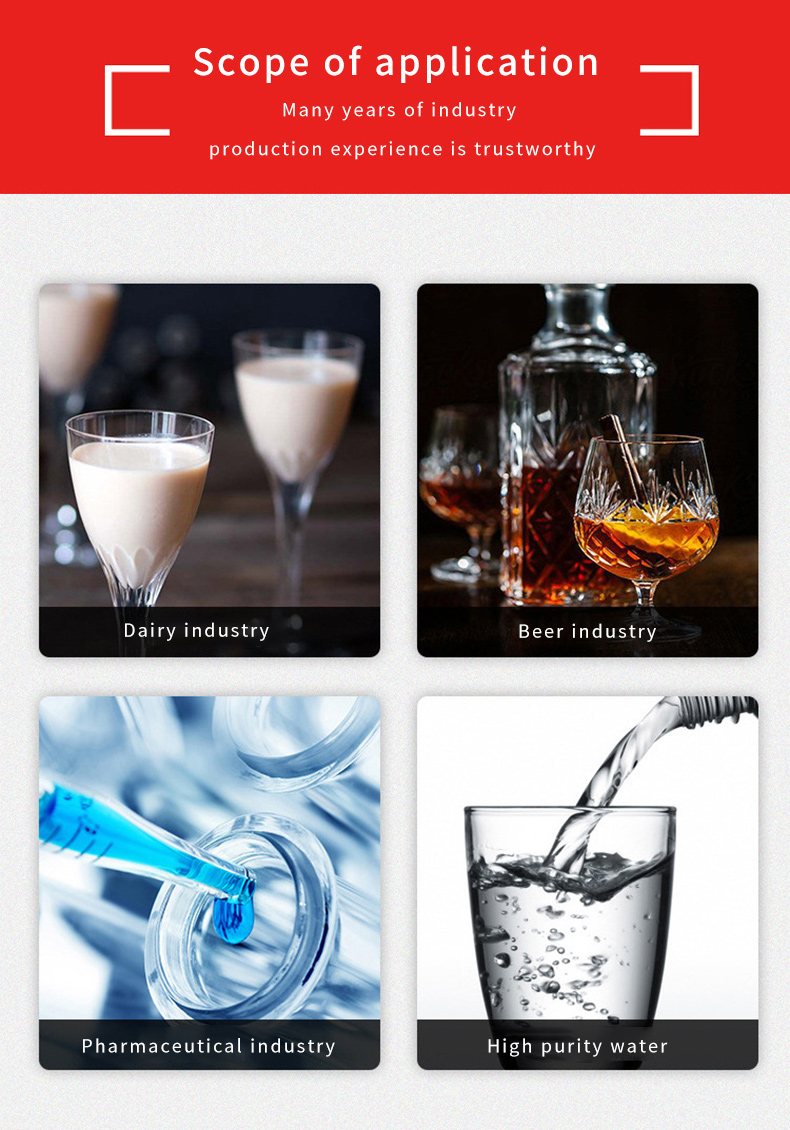

2. It is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various materials containing particles.

3. It usually adopts a piston-type or servo motor-driven screw metering device to achieve accurate quantitative measurement of materials by accurately controlling the piston stroke or the number of screw rotations.

4. It adopts advanced control systems and high-quality mechanical components to ensure that the equipment can still operate stably under high load.

5. The overall structure of the equipment is sturdy and durable, and the key components are carefully designed and selected, with a long service life.

In modern production, efficient and accurate paste filling equipment is essential for many industries. Our fully automatic paste filling machine, with advanced technology and excellent performance, provides a reliable solution for the filling of paste products.

Equipped with a high-precision metering system, the filling volume can be accurately controlled with a very small error range, ensuring that the paste content in each package is consistent and meets strict quality standards.

With efficient filling capabilities, it can complete the filling of a large number of products in a short time, improve production efficiency and meet the needs of large-scale production.

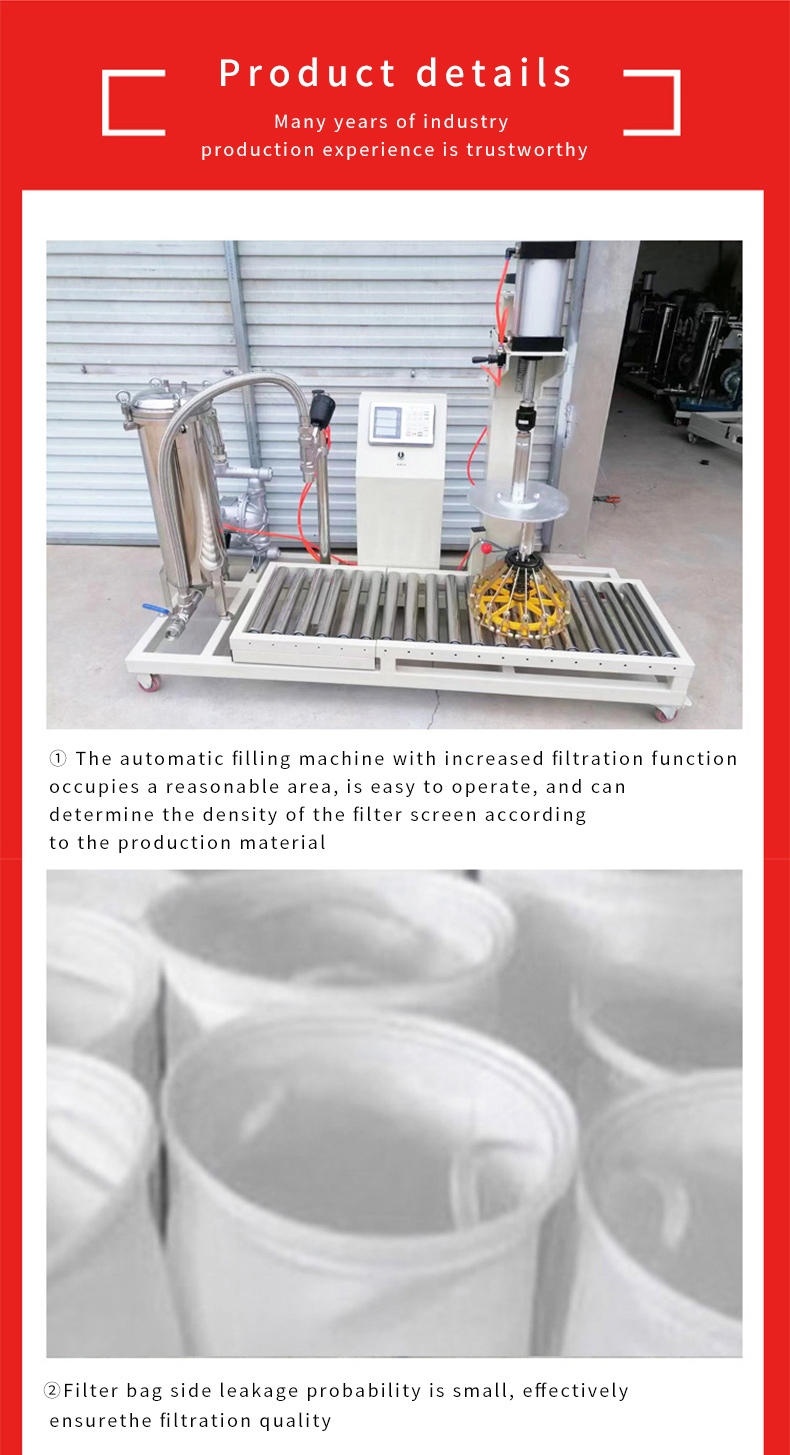

Product name:Automatic weighing heavy pressure cap filter filling machine

Product use:Filling liquid

Packaging type:barrel

Product principle:normal pressure

Scope of application:Chemical food, etc.

Filling volume:50-1000ML

With advanced PLC control system and human-machine interface, operators can easily set and adjust filling parameters such as filling speed, filling volume, filling times, etc. through the touch screen to achieve automated production.

It can adapt to a variety of packaging containers of different specifications, whether it is bottles, cans or hoses, and filling operations can be carried out by simply adjusting the relevant parts of the equipment. It has strong flexibility and versatility.

The use of high-quality components and solid mechanical structure, and strict quality inspection and debugging ensure that the equipment is stable and reliable during long-term operation, reduce the probability of failure, and reduce maintenance costs.