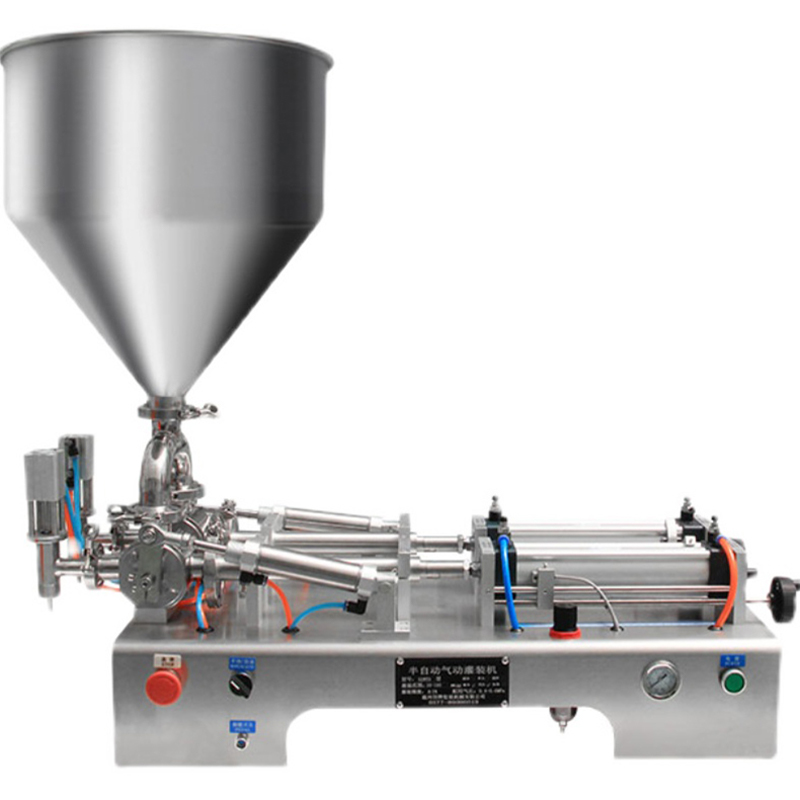

High precision paste filling machine

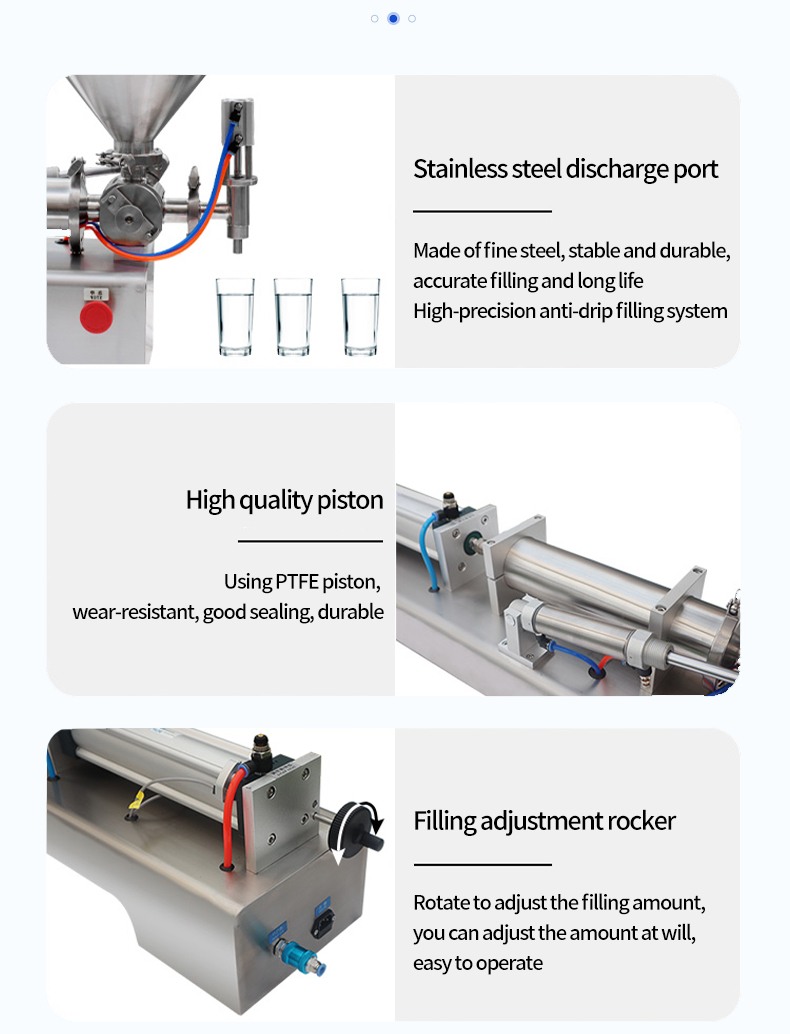

1. The high-precision metering device can accurately control the filling amount of the paste, and the error can be controlled within a very small range.

2. It can ensure that the filling height of the paste in the packaging container is uniform and consistent, avoiding overfilling or underfilling.

3. It has a high filling speed and can complete the filling of a large number of packaging containers in a short time, improving production efficiency.

4. It can be applied to various paste materials with different viscosities and properties. By adjusting the parameters of the equipment and replacing some parts, high-precision filling of different pastes can be achieved.

5. The structural design of the equipment is reasonable, easy to disassemble and clean, without sanitary dead corners, and can effectively prevent paste residue and bacterial growth.

In modern production, the filling accuracy requirements for paste products are increasing day by day. Our high-precision paste filling machine, with advanced technology and excellent performance, provides enterprises with efficient and accurate paste filling solutions.

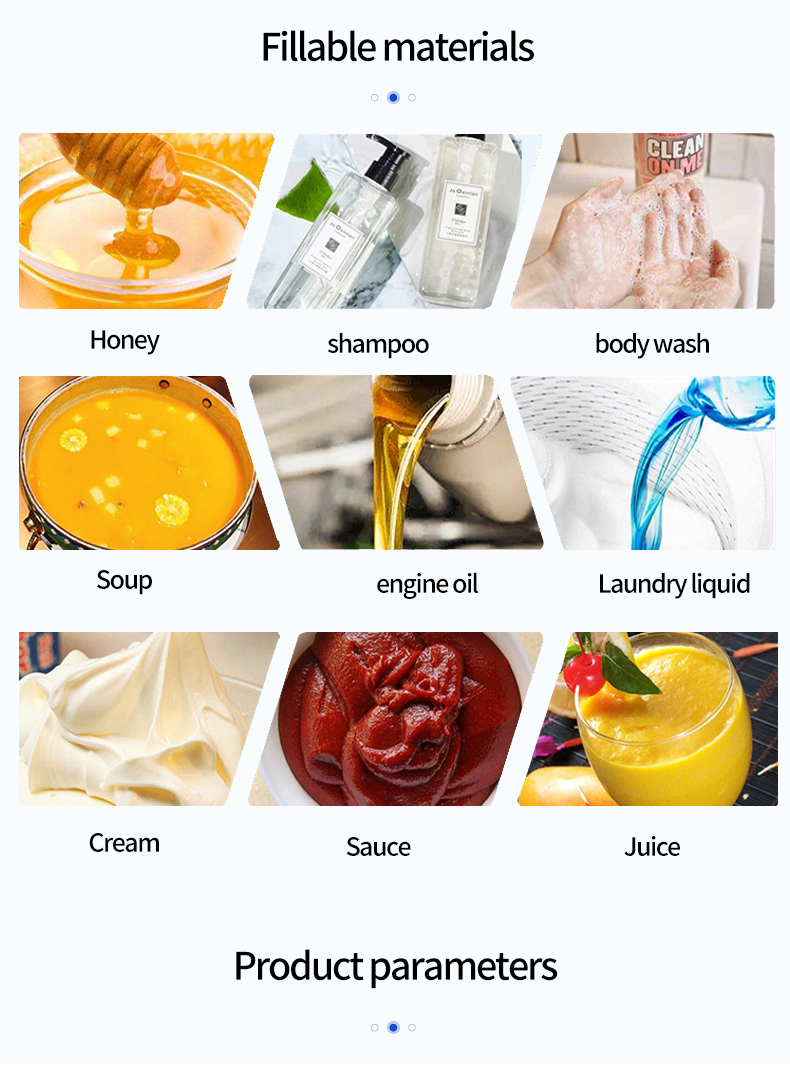

The filling accuracy is extremely high, which can meet the precise requirements of different industries for the filling volume of pastes. Whether it is a small dose of ointment, essence, or a large dose of jam, sauce, etc., it can achieve accurate filling to ensure that the paste content in each package is consistent and reduce product quality differences.

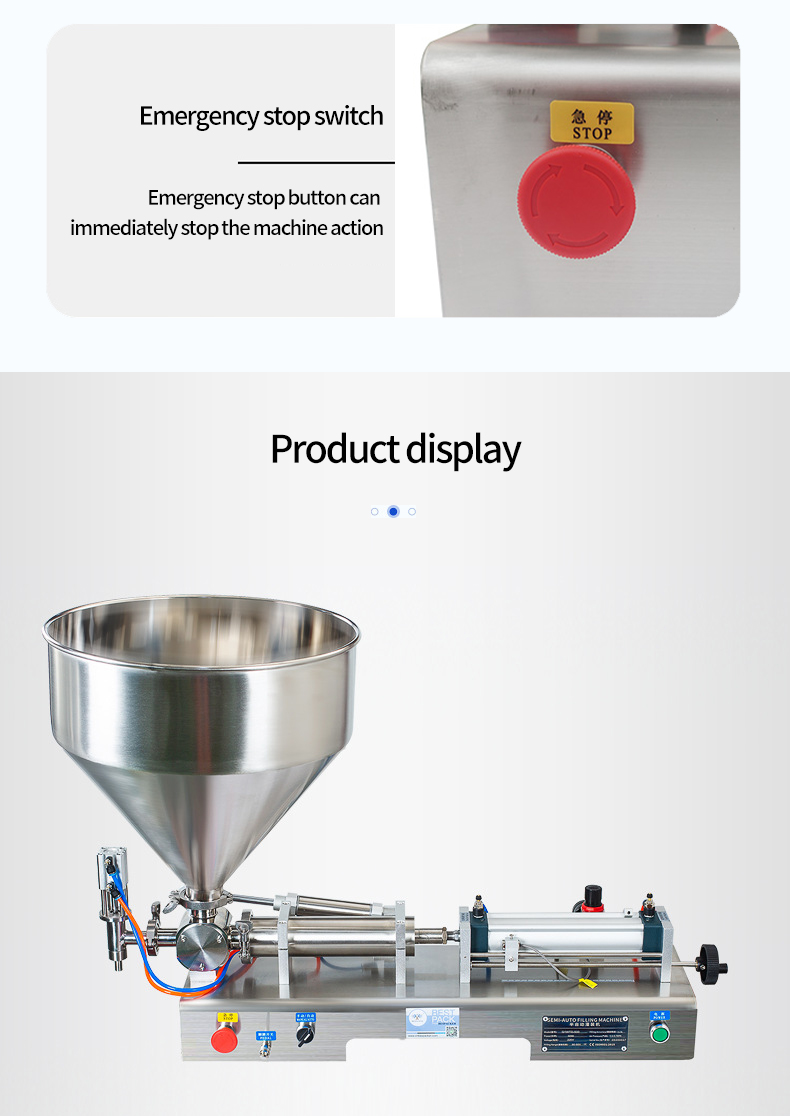

It has efficient filling capabilities and can achieve fast filling and improve production efficiency while ensuring high precision. The equipment uses high-quality components and a solid mechanical structure, and has undergone strict quality testing and debugging.

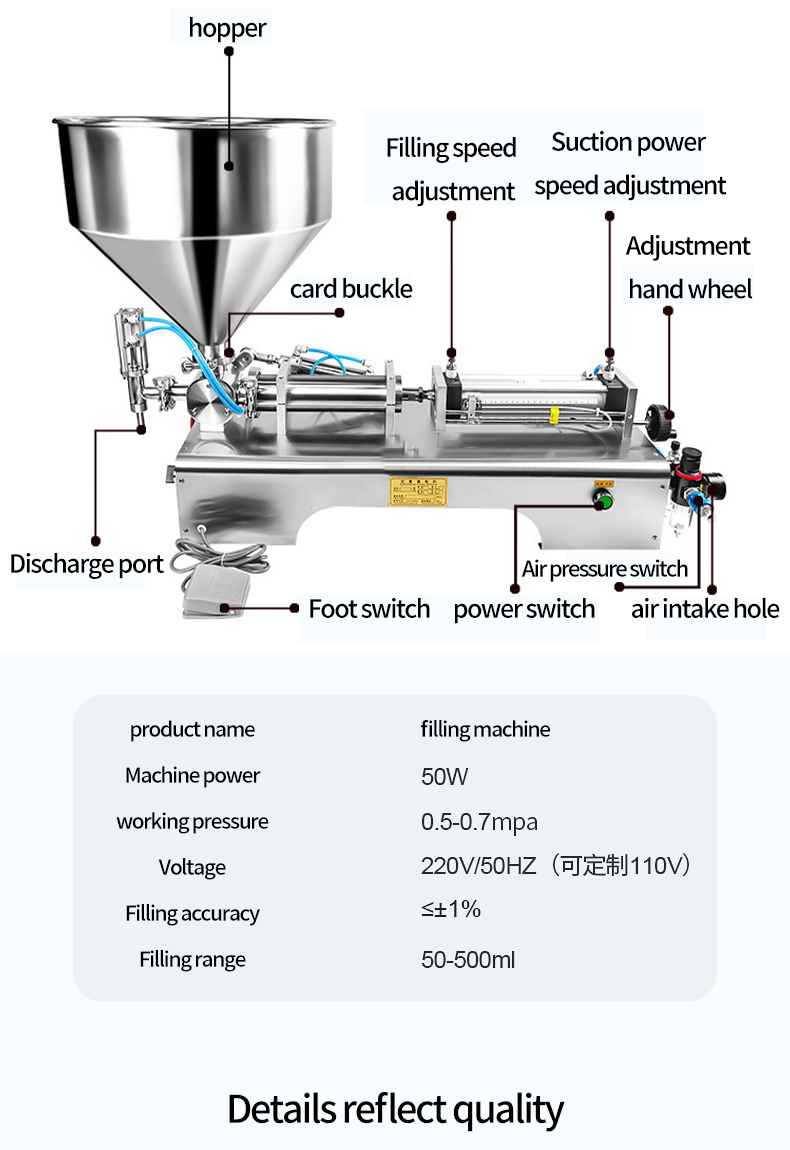

Equipped with a user-friendly operation interface, operators can easily set and adjust filling parameters such as filling volume, filling speed, filling times, etc. through the touch screen.

product name:filling machine

Machine power:50W

working pressure:0.5-0.7mpa

Voltage:220V/50HZ (110V can be customized)

Filling accuracy:≤±1%

Filling range:50-500ml

The parts in contact with the paste material are made of stainless steel that meets food hygiene standards or medical standards. The surface is smooth, without dead corners, and easy to clean and disinfect.

It can adapt to a variety of paste materials with different viscosities and properties. At the same time, it can be compatible with packaging containers of various shapes and specifications. You only need to simply adjust the relevant parts of the equipment to achieve rapid switching production of different products.

It can realize full-process automation operations such as automatic loading, automatic filling, automatic sealing, automatic labeling, etc., reduce manual intervention, and improve production efficiency and product quality stability.