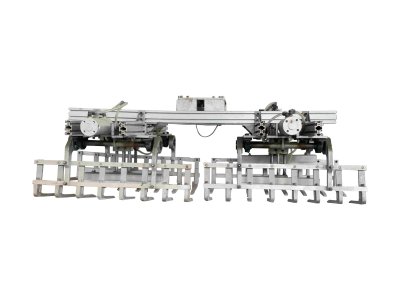

Automatic cleaning of particle tank machine

1. Save labor cost:

No need to manually carry out tedious cleaning work, reducing the need for a large number of cleaning personnel.

It reduces the fatigue and mistakes that may be caused by manual operation, and improves the overall work efficiency.

2. Improve cleaning efficiency and hygiene standards:

Using professionally designed cleaning procedures and systems, it is possible to reach all corners of the machine and completely remove residual particles and dirt.

Strictly follow hygiene standards, effectively prevent bacterial growth and cross-contamination, and ensure product quality and safety.

3. Increase production continuity:

The cleaning process is completed quickly, reducing equipment downtime and allowing production to proceed more consistently.

Help to meet the continuous demand for products in the market and improve the supply capacity of enterprises.

4. Protect the equipment and extend the service life:

Regular automatic cleaning can reduce the wear and corrosion of dirt and particles on machine components.

Reduce the incidence of equipment failure, reduce maintenance costs, extend the service life of the filling machine.

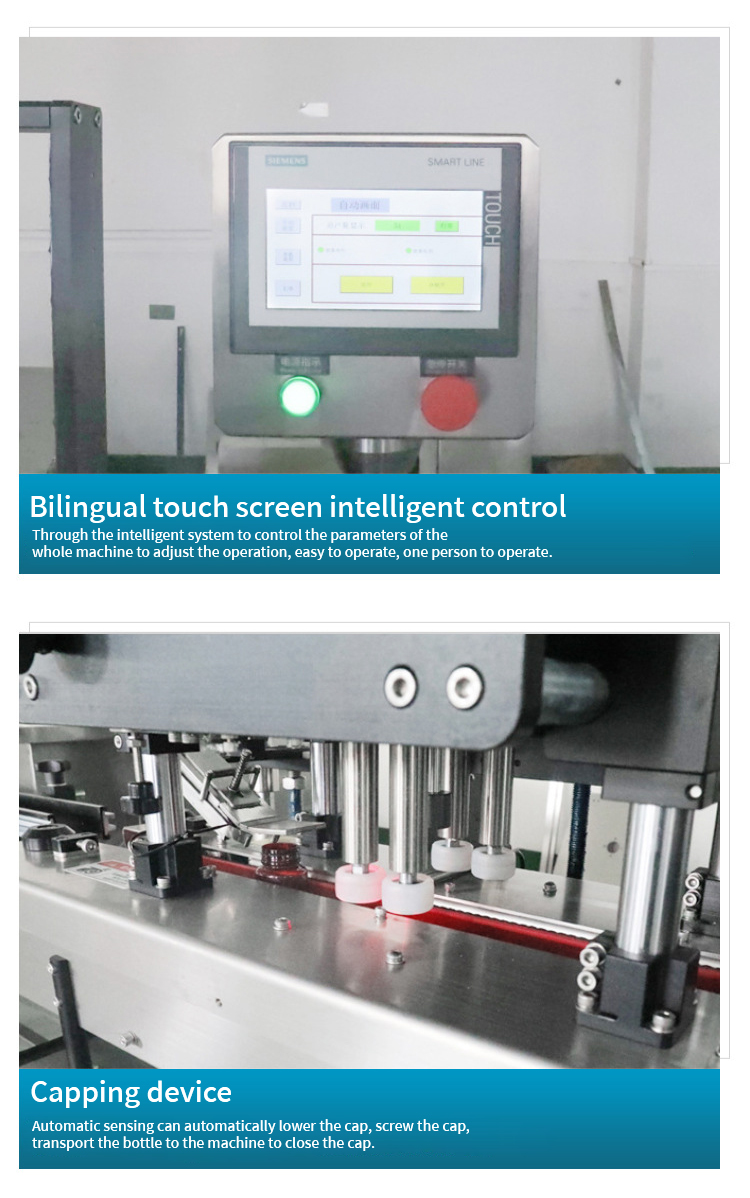

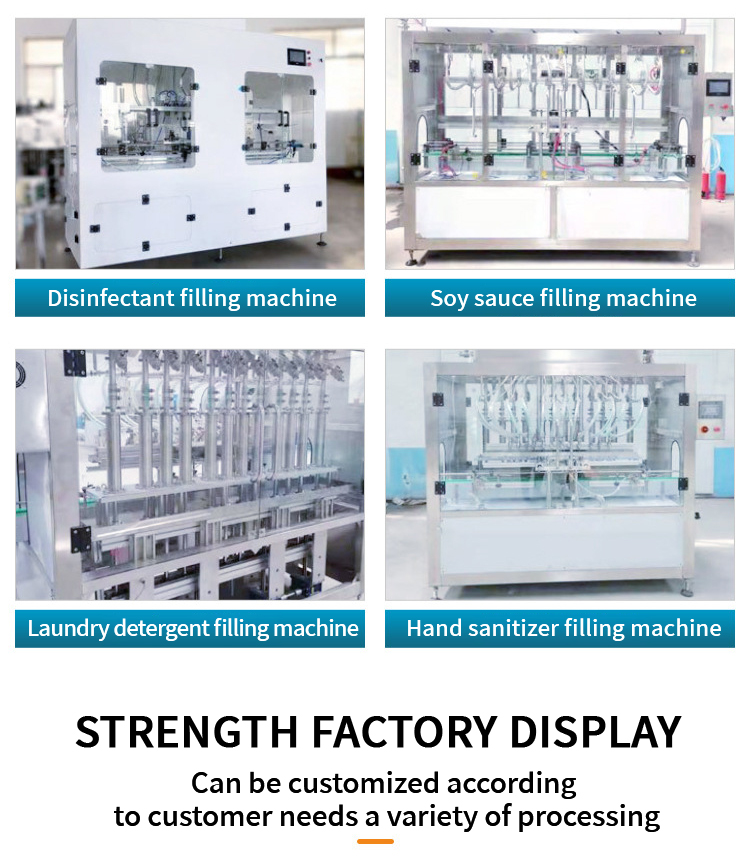

Automatic cleaning filling machine is a highly automated filling equipment with advanced cleaning functions, designed to meet the needs of modern industrial production for efficient, hygienic and accurate filling.

Automatic cleaning and filling machine Model: BS- filling machine (can be customized)

The number of filling heads of the automatic cleaning and filling machine: single head /2 head /4 head /6 head /8 head /10 first class

Suitable bottle height of automatic cleaning and filling machine: 0-500CM (can be customized)

Suitable bottle diameter of automatic cleaning and filling machine: 0-50CM (can be customized)

Automatic cleaning and filling machine filling accuracy: about 0.5% (depending on the material)

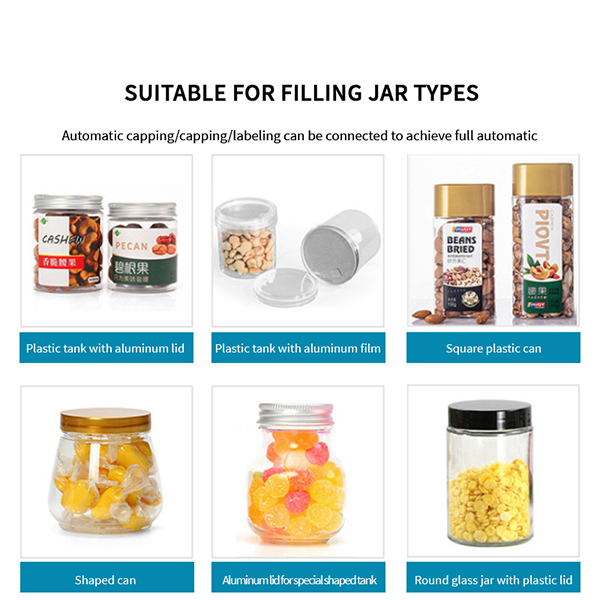

Filling type of automatic cleaning and filling machine: bottle/tube/jar/tinplate/self-supporting bag, etc

Automatic cleaning and filling machine power specifications: 220V, 50/60HZ(different countries can be customized)

Automatic cleaning and filling machine power: 1.2KVA(different countries can be customized)

The scope of application of automatic cleaning and filling machine: powder/liquid/paste/paste/particle/powder, etc