Pellet Filling Machine

Pellet Filling Machine

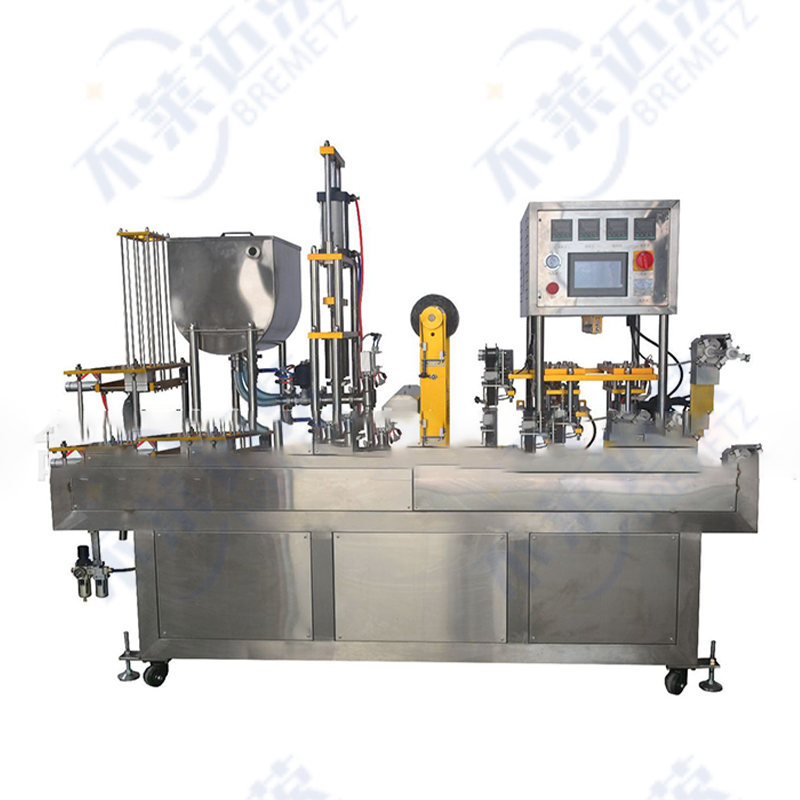

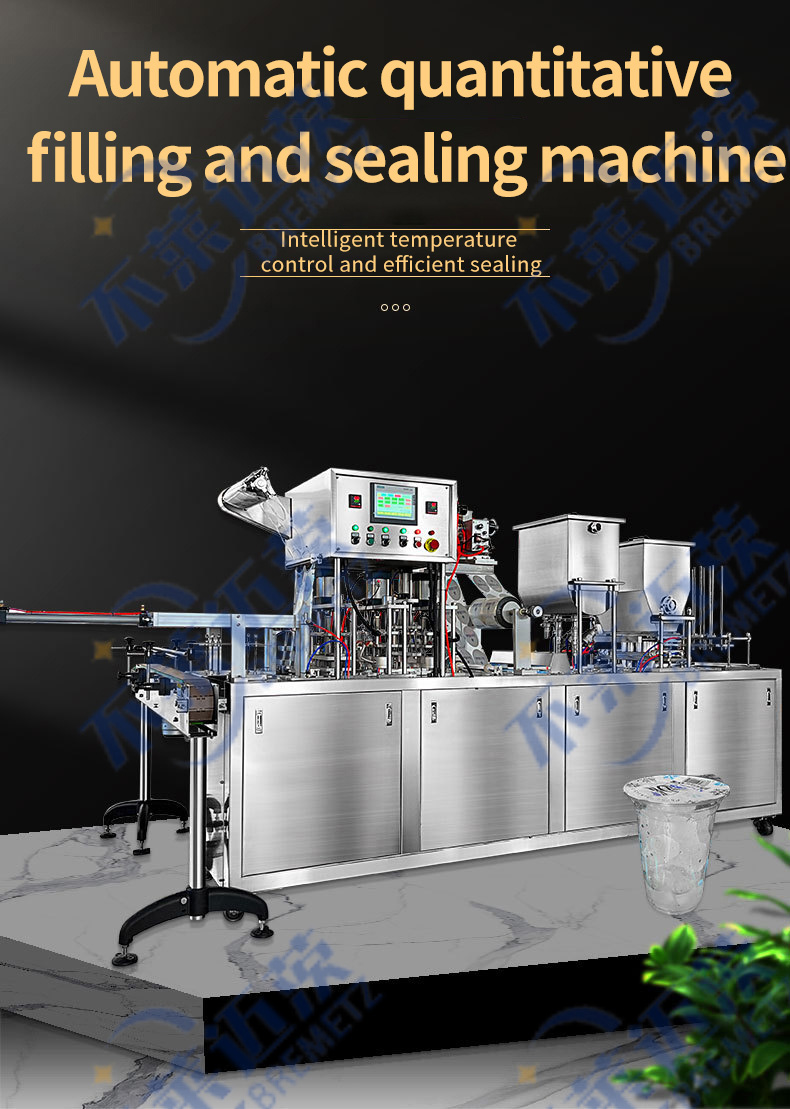

The product is equipped with a relatively high-precision electronic scale to weigh and measure materials. Controlled by the measured data, the quality can be measured with high accuracy. On the other hand, the work intensity of manual operations is reduced by humanizing manual operation steps, interface optimization, and equipment settings, thereby improving the efficiency of the entire production process.

Because it is filling granular materials. Although granular materials can undergo certain shearing movements compared to liquid materials, the granular medium is larger after all. Therefore, the flow viscous resistance generated is also relatively large, and it is difficult to achieve good filling results using gravity or simple pressure difference alone. Therefore, a vibrating method is added to the feeding path to assist gravity in the feeding process. On the other hand, the vibrating component must not damage the material, and the frequency of vibration must be relatively high.

The design and composition of the product are generally open, and the operating system also supports secondary development, thereby further modularizing the entire integrated circuit board and supporting more automated settings. The unloading method comprehensively meets the filling needs of granular solids, and the final process is completed through multiple process steps such as material lowering, vibration excitation, weight measurement, door opening, and material transportation. Since it is specially used for granular materials, the product life will be relatively long (there is no possibility of being corroded by liquid materials or accelerated oxidation). Product design is easy for daily maintenance.