Full Servo Pillow Type Automatic Packaging Machine

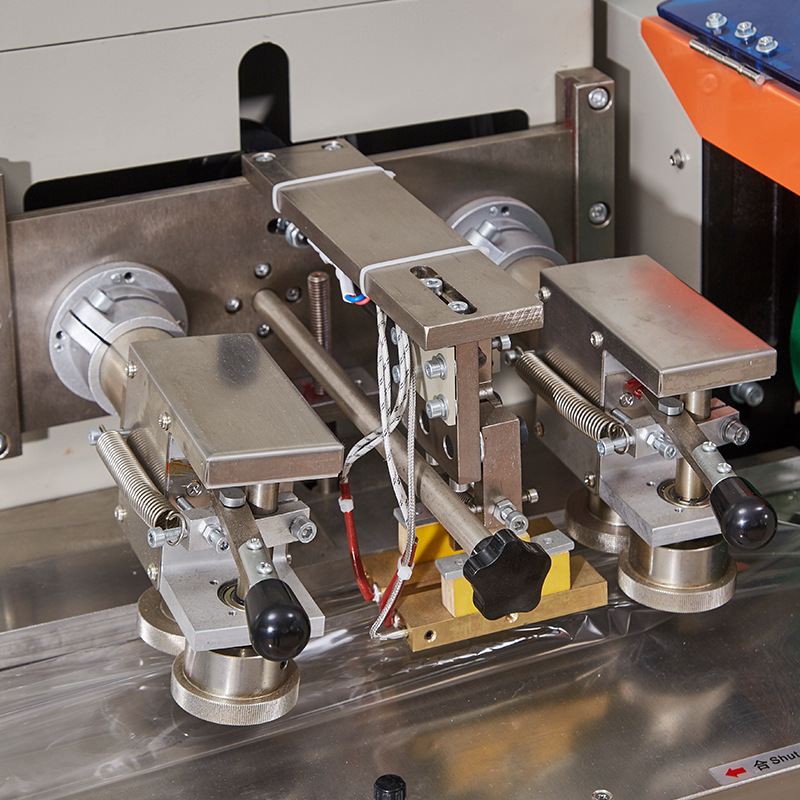

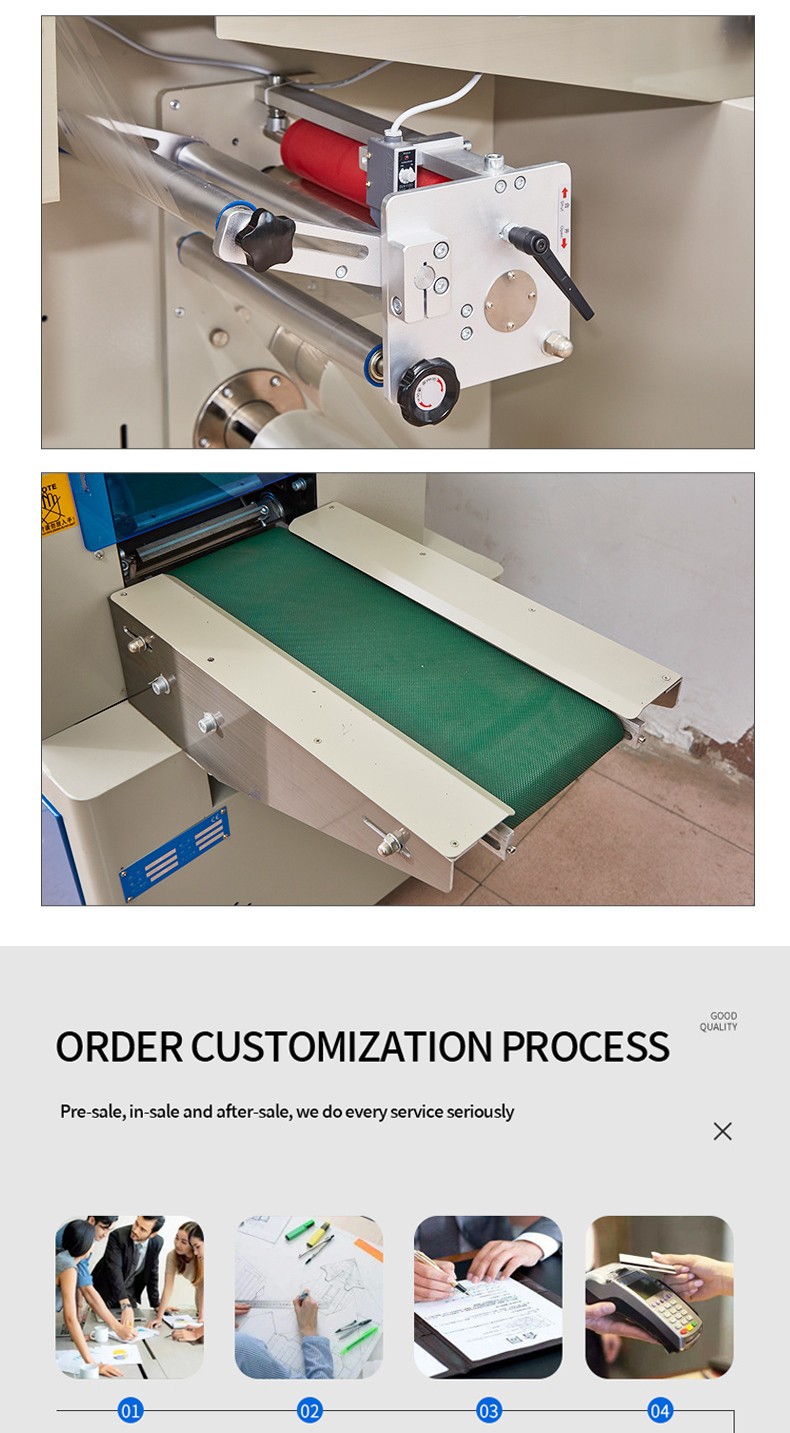

1. Accurate sealing and cutting position: The high-sensitivity photoelectric eye color mark is used to track the digital input of the sealing and cutting position, and the precise drive of the servo motor can ensure the high precision of the sealing and cutting position.

2. Accurate packaging size: Through the coordinated work of the precise control system and the servo motor, the length, width and height of the packaging bag can be accurately adjusted according to the size requirements of different products.

3. Full servo motor drive: Using the servo motor as the power source, mechanical wear and transmission error are avoided, and the operation is more stable and reliable.

4. High-speed packaging capability: It has a high packaging speed of 60-150 bags/minute, which can meet the needs of large-scale production and effectively improve production efficiency.

5. Fast mold change and adjustment: The structural design of the equipment is reasonable, and the mold change and adjustment process is simple and fast. It can complete the switching of different product packaging specifications in a short time, which improves the flexibility and adaptability of the equipment.

6. Simple mechanical structure: The mechanical structure of the equipment is relatively simple, with fewer transmission parts, which reduces the number of vulnerable parts and reduces the maintenance cost and maintenance workload of the equipment.

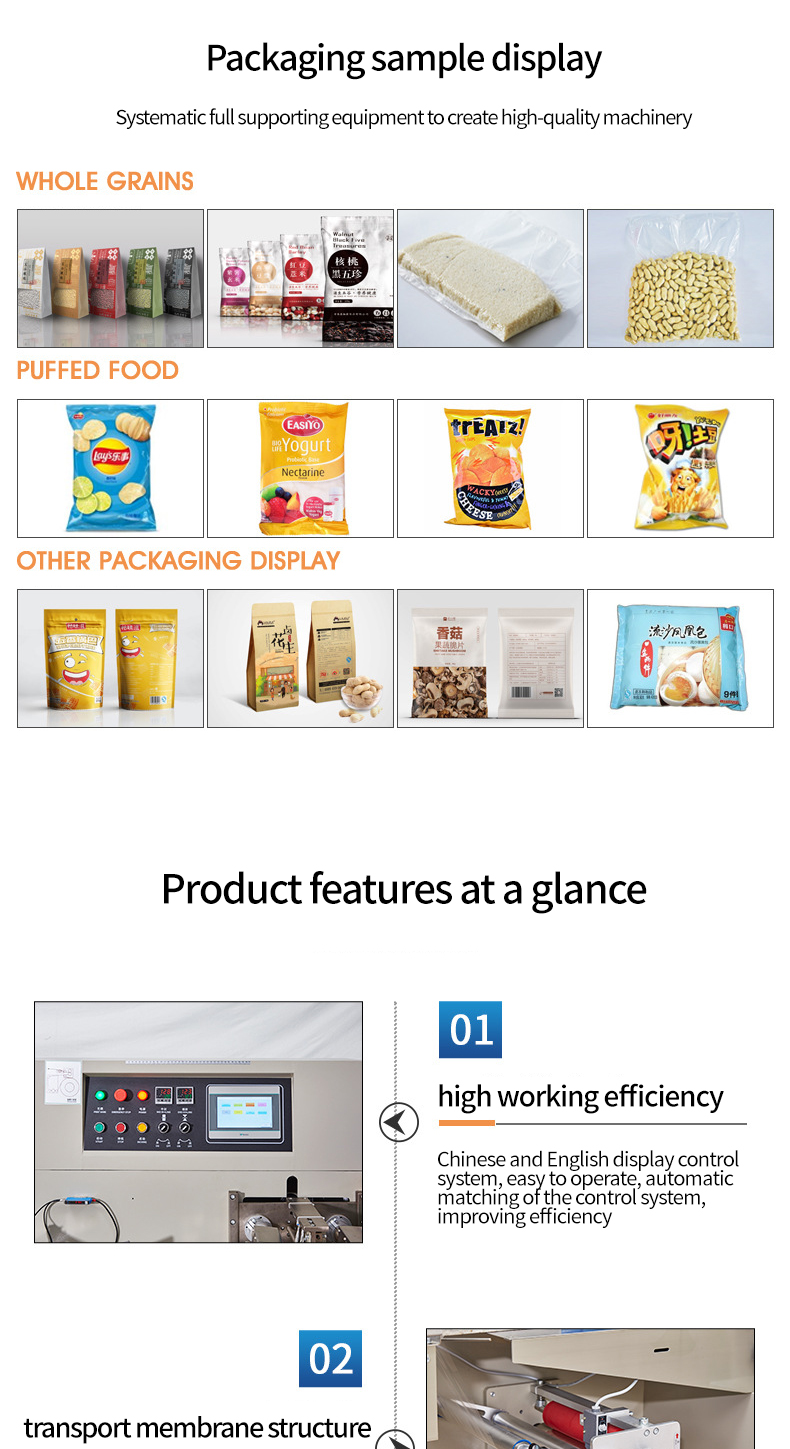

Full Servo Pillow Type automatic packaging machine is a fully servo-driven pillow type automatic Packaging Machine with the characteristics of high efficiency, precision and stability. It is widely used in many industries such as food, daily necessities, hardware, and medicine. It can automatically package products of various shapes and sizes.

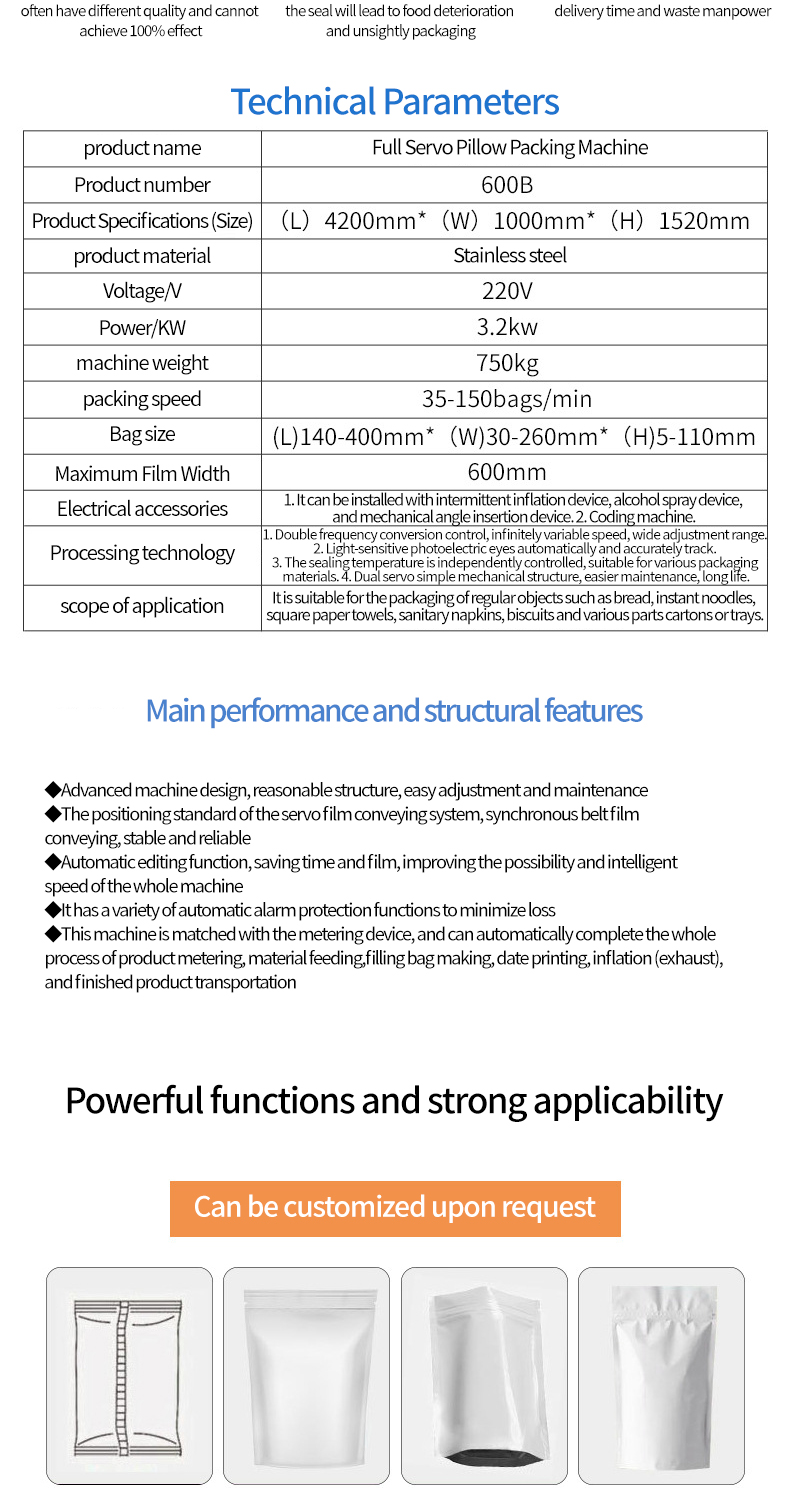

product name:Full Servo Pillow Packing Machine

Product number:600B

Product Specifications (Size):(L) 4200mm*(W) 1000mm*(H)1520mm

product material:Stainless steel

Voltage/V:220V

Power/KW:3.2kw

machine weight:750kg

packing speed:35-150bags/min

Bag size:(L)140-400mm*(H)30-260mm*(H)5-110mm

Maximum Film Width:600mm

Electrical accessories

1. It can be installed with intermittent inflation device, alcohol spray device, and mechanical angle insertion device. 2. Coding machine.

Processing technology

1. Double frequency conversion control, infinitely variable speed, wide adjustment range.

2. Light-sensitive photoelectric eyes automatically and accurately track.

3. The sealing temperature is independently controlled, suitable for various packaging materials.

4. Dual servo simple mechanical structure, easier maintenance, long life. It is suitable for the packaging of regular objects such as bread, instant noodles, square paper towels, sanitary napkins, biscuits and various parts cartons or trays.

Main performance and structural features

Advanced machine design, reasonable structure, easy adjustment and maintenance.

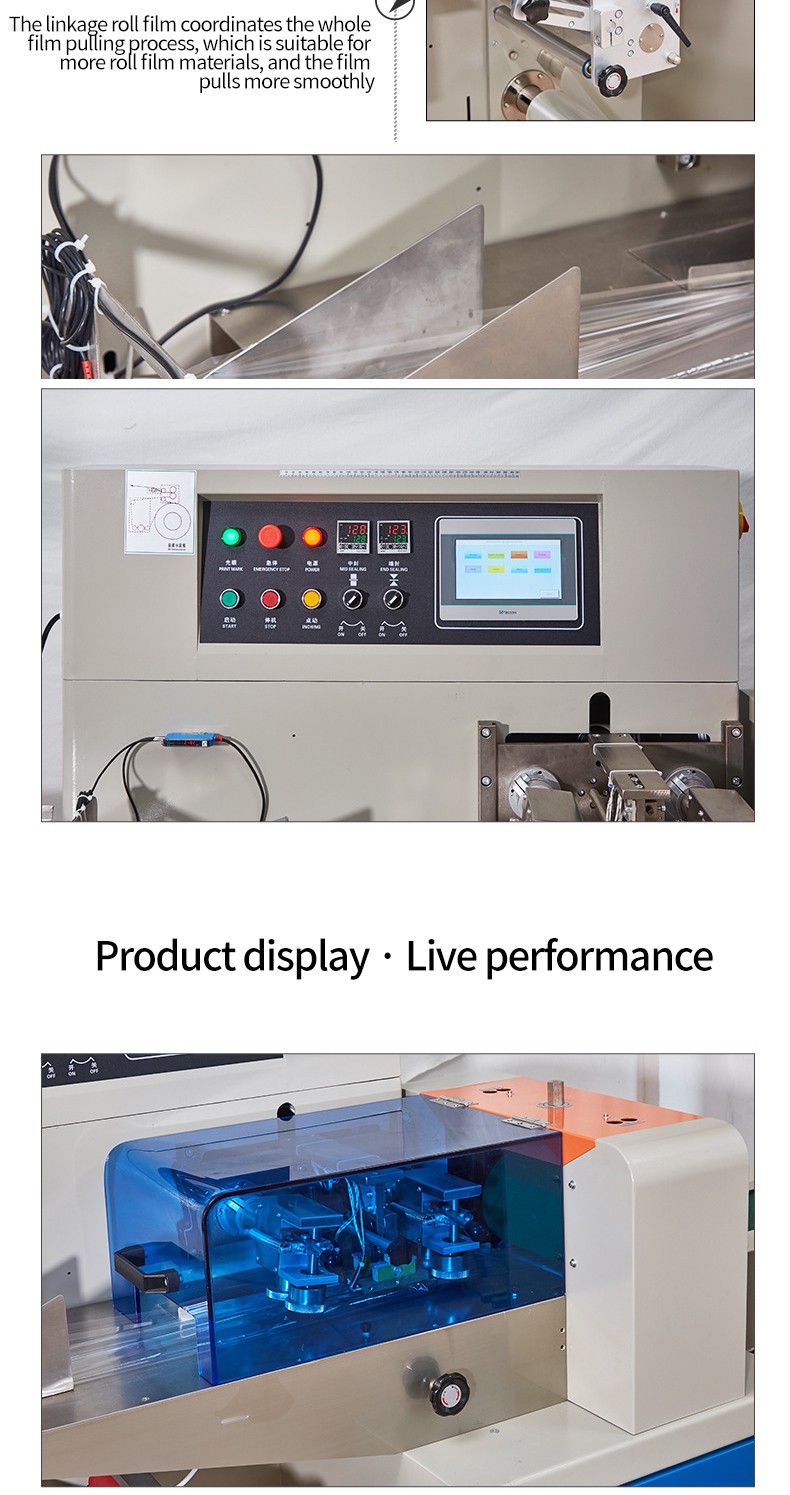

The positioning standard of the servo film conveying system, synchronous belt film conveying, stable and reliable.

Automatic editing function, saving time and film, improving the possibility and intelligent speed of the whole machine.

It has a variety of automatic alarm protection functions to minimize loss.

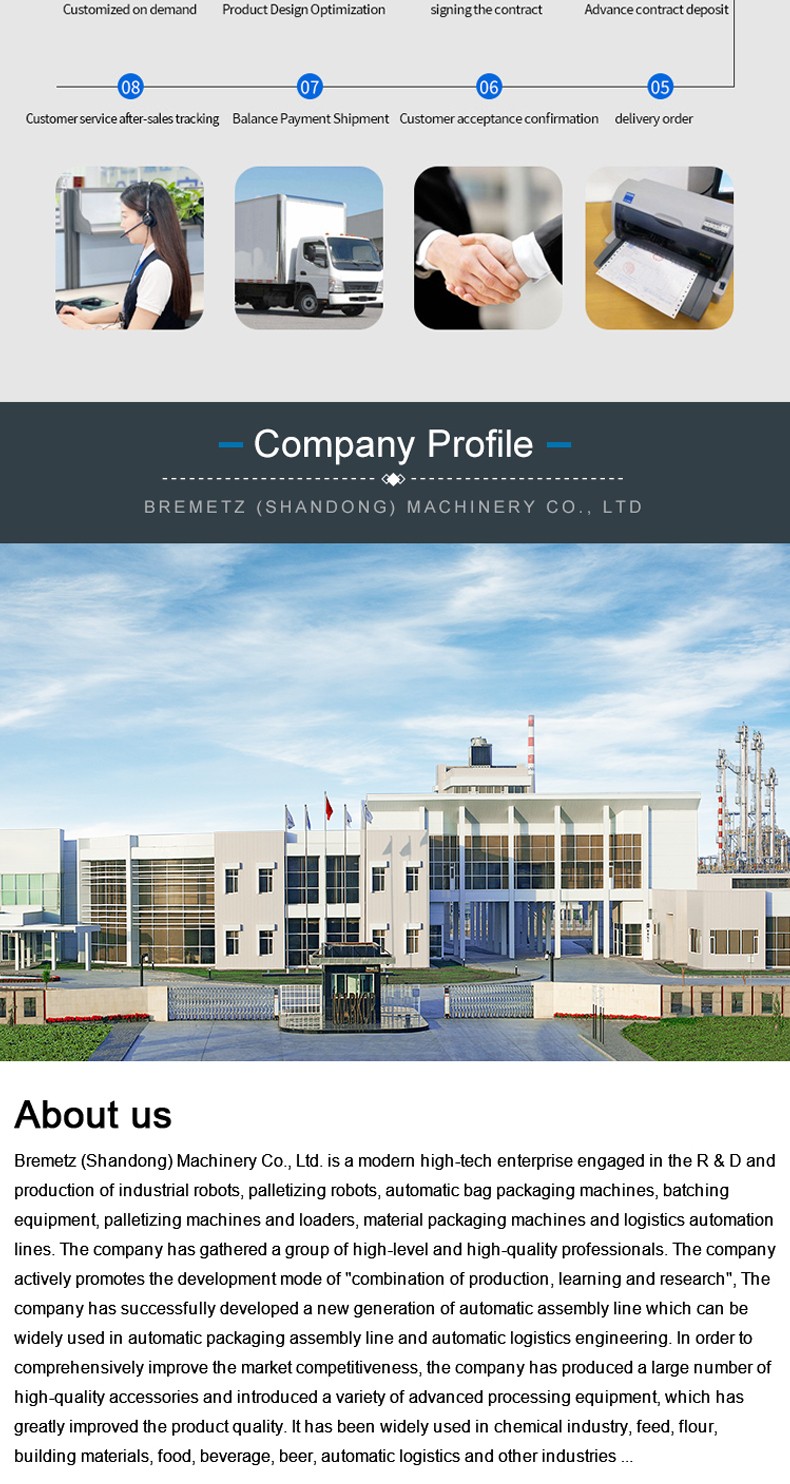

This machine is matched with the metering device, and can automatically complete the whole process of product metering, material feeding, filling bag making, date printing, inflation (exhaust), and finished product transportation.

Full servo motor drive and PLC intelligent control avoid mechanical wear and transmission error, make the operation more stable and reliable, and can run continuously for a long time, reducing the failure rate of equipment and improving production efficiency.

Through the touch screen control system, operators can easily perform operations such as equipment parameter setting, operating status monitoring, fault alarm query, etc. The rapid mold change and adjustment function also greatly improves the flexibility and adaptability of the equipment.

It can adapt to various types of packaging films, including heat-sealable composite films, paper-film composite films, aluminum foil composite films, food-grade composite films, heat shrinkable films, etc., and can package products of various shapes, sizes and properties.

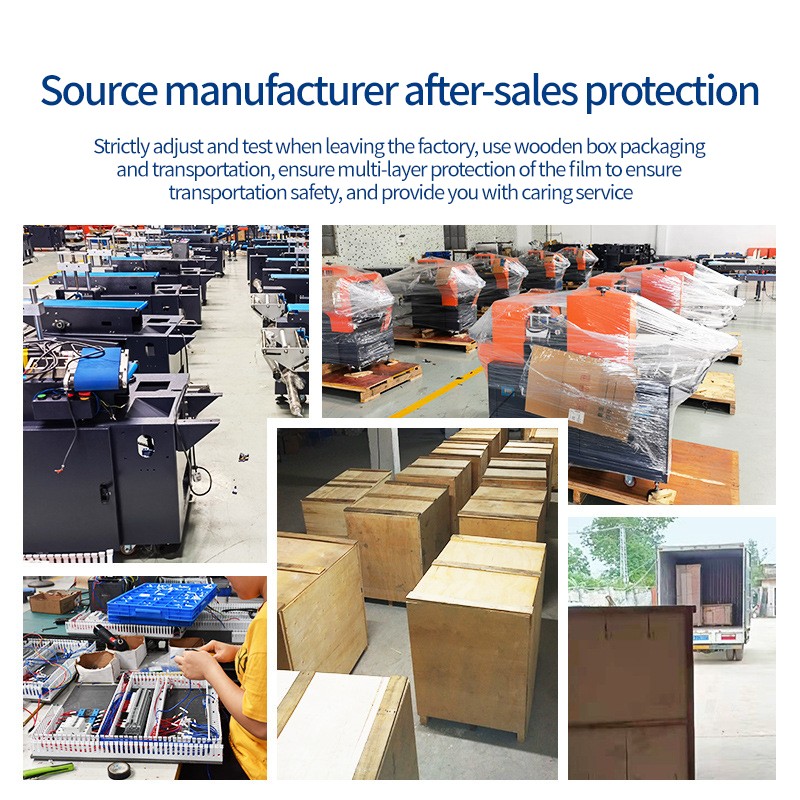

Provide customers with professional operation training to ensure that operators can master the equipment's operation methods, parameter settings, daily maintenance and other skills, so that they can operate the equipment correctly and safely and bring into play the best performance of the equipment.

Teach customers basic equipment maintenance knowledge, including daily maintenance work such as equipment cleaning, lubrication, and tightening, as well as simple fault troubleshooting and handling methods, to help customers extend the service life of the equipment and reduce production delays caused by equipment failures.

Establish a complete after-sales service network, and respond quickly to customer maintenance requests, arrange technicians to communicate with customers in a timely manner, understand the fault situation, and arrive at the site for maintenance as soon as possible.

Regularly visit customers to understand the usage and operating status of the equipment, identify potential problems in a timely manner, and provide customers with corresponding solutions and suggestions to prevent failures.

According to the special needs of customers, we provide customized after-sales service solutions, such as equipment modification, adding special functions, etc., to help customers better meet the requirements of production process and product packaging, and improve their market competitiveness.