Intelligent pillow packaging machine

1. The use of advanced sensors and control systems, such as PLC, servo motors, etc., can accurately control various parameters in the packaging process.

2. With automatic detection and automatic adjustment functions, it can automatically adjust packaging parameters according to changes in packaging materials, product size differences, etc.

3. The built-in fault self-diagnosis system can monitor the operating status of the equipment in real time. Once a fault occurs, the fault location and cause can be quickly and accurately displayed.

4. Advanced design, reasonable structure, and efficient film feeding and conveying system can achieve high-speed continuous packaging.

5. By accurately controlling the heat sealing temperature, pressure and time, and using high-quality heat sealing components, the sealing performance of the packaging bag is ensured to be good.

The intelligent pillow packaging machine is a packaging equipment that integrates advanced automation technology, precision mechanical design and intelligent control system. It is specially used for efficient, accurate and high-quality pillow packaging of various products.

It has automatic detection function, which can monitor the tension of packaging film, position and quantity of products in real time. Once an abnormal situation occurs, it will automatically stop and sound an alarm to ensure the stability and reliability of the packaging process and reduce the defective rate.

The intelligent memory function can store the packaging parameters of a variety of different products, making it convenient to quickly switch packaging specifications, adapt to diverse production needs, and greatly improve production efficiency.

The optimized mechanical structure design ensures smooth and stable material transportation, reduces jamming during packaging, and further ensures the continuity and efficiency of packaging.

The high-precision temperature control system ensures that the sealing temperature is uniform and stable, the seal is firm and beautiful, effectively prevents product leakage and deterioration, extends the shelf life of the product, and improves the overall quality image of the product.

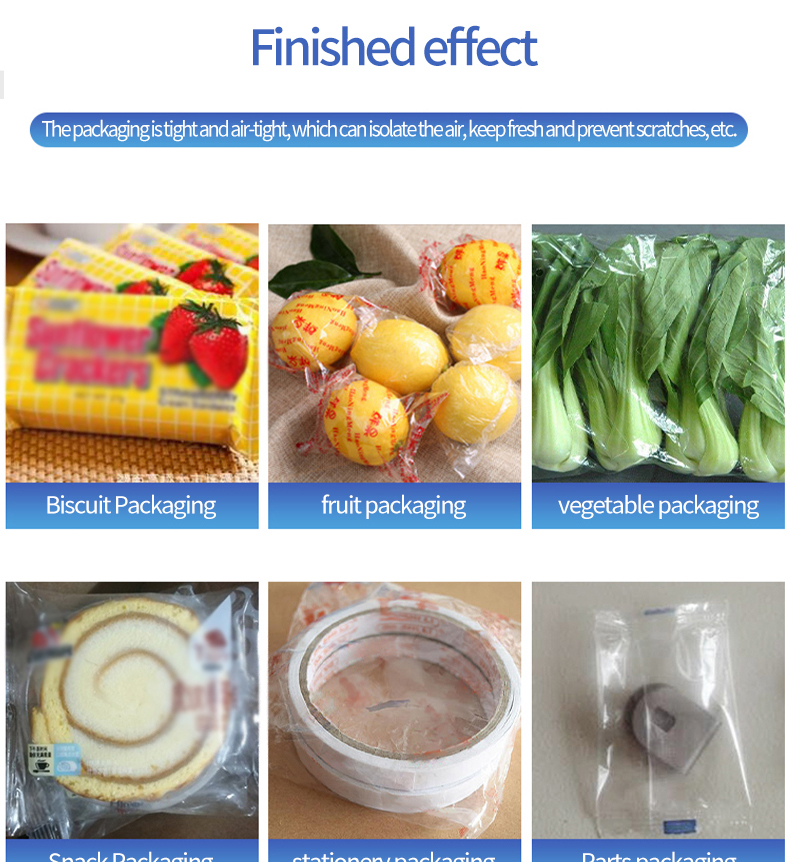

By replacing different formers and conveyor belt accessories, it can adapt to the packaging of products of various shapes and sizes, such as square, round, oval, etc. The packaging range is wide, ranging from small parts to larger daily necessities.

The overall structure is reasonably designed and the parts are compactly arranged, which is convenient for daily cleaning, maintenance and repair. The key components are made of high-quality and durable materials with a long service life, which reduces the failure rate and maintenance cost of the equipment.