Automatic palletizer sucker gripper

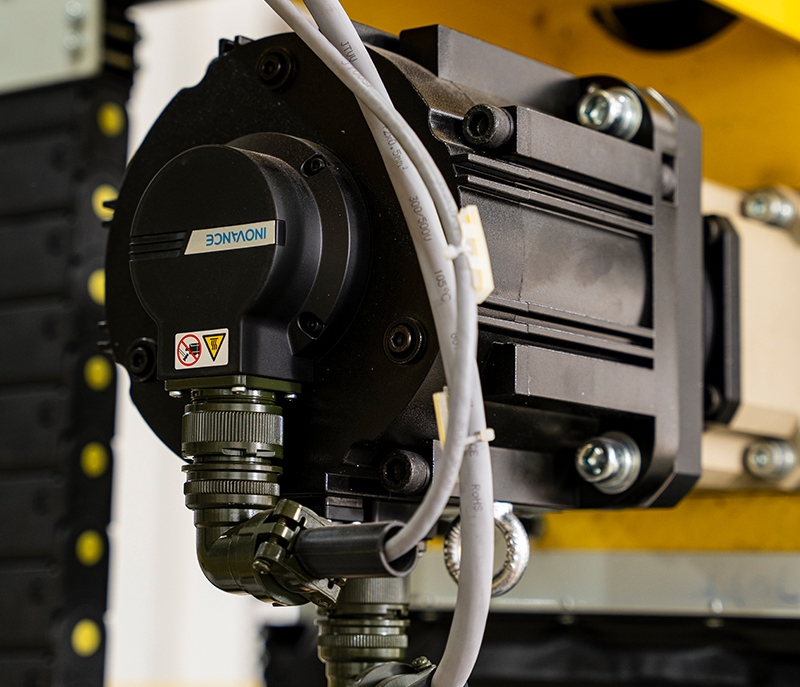

The mechanical gripper usually uses compressed air as the power source, and realizes the movement of fingers through the transmission mechanism. According to the different movement trajectory of the finger when holding the workpiece, the mechanical gripper is divided into:

(1) Arc opening and closing type driven by the transmission mechanism, the movement track of the finger end is arc, this kind of gripper has strict requirements for the size of the workpiece being clamped, otherwise it may cause the workpiece state disorder.

(2) Circular arc parallel opening and closing type This type of gripper makes equal opening and closing motion when the two fingers work, and the motion track of the finger end is an arc. The gripper shown in the figure "Circular arc parallel opening and Closing type" is the two cases in which the parallelogram transmission mechanism drives the equal opening and closing of the finger, in which the mechanism shown in figure (a) advances the finger end during the clamping.

(3) Linear parallel opening and closing type The motion trajectory of the two fingers of this type of gripper is straight, and the gripper surface of the two fingers is always equal, as shown in the figure "Linear parallel opening and Closing Type". A CAM mechanism is used to realize the parallel opening and closing of two fingers. A diagonal CAM slot is opened on the sliding block of each finger. When the piston rod moves up and down, a roller installed at its end moves in the CAM slot to realize the parallel clamping movement of fingers. The rack and pinion mechanism is adopted. When the rack at the end of the piston rod drives the gear to rotate, the rack on the finger moves in a straight line, so that the two fingers open and close equally to grip the workpiece.

A gripper is a device that holds an object and controls it. It is capable of holding and releasing objects while performing certain actions. Exercise equipment often mimics the movement of the human body and, in the case of grippers, the movement of the fingers. The "finger" itself is not a gripper, they are just a special custom tool used to grip the object, called the "clip". The most widely used gripper is the pneumatic gripper; It is essentially a cylinder powered by compressed air. When air is supplied, the gripper clip will approach the object and hold it firmly in order to perform other operations, and when the direction of the air changes, the gripper will release the object. Typical applications are to change the direction of an object or to move an object in a selective placement operation. When clamping the workpiece, there should be a certain force constraint and shape constraint to ensure that the workpiece to be clamped in the process of moving, staying and loading, should be completely loosened. In addition, it should also ensure that the geometric deviation of the workpiece holding attitude is reproduced within the given tolerance zone.